Hongfa Германия Ytong автоклавная машина для изготовления строительных блоков из аэрированного Бетона AAC от

- Категория: >>>

- Поставщик: Guangxi Hongfa Heavy Machinery Co. Ltd.

Сохранить в закладки 1600634363485:

Описание и отзывы

Характеристики

Hongfa Germany Ytong Autoclaved Aerated Concrete AAC Building Block Making Machine Manufacturer Plant

High technology for AAC:

1.500kg/m3,600kg/m3,700kg/m3

2.Raw material :sand or fly ash

3.Its weight is 1/4 concrete

4.ISO/CE

1.light weight .Areated concrete density is usually 400-700kg/m3,(according the market in produce ),same as 1/3 of clay block and 1/5 common concrete.So use the Light block can reduce the weight of the build more,and also reduce the beam of roof and pillar press best.then you can see,it can save the material and cost,it also fighting shaking.

2.keeping temperature .It has many are porous,the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or 1/5 of clay brick,so it is best materials now in the world.

Hongfa Germany Ytong Autoclaved Aerated Concrete AAC Building Block Making Machine Manufacturer Plant

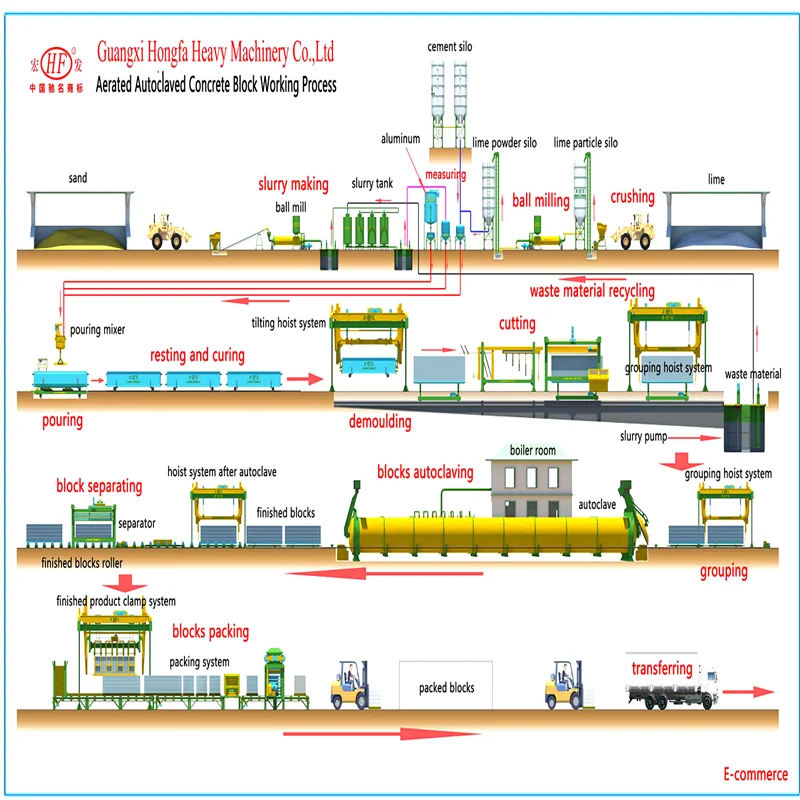

Main process flow of Made-in-China AAC brick making machine production line concrete block plant aac block manufacturing plant cost

Hongfa is a complete solution supplier and a complete set of equipment production

supplier.

1.Raw material preparation for AAC plant:

A, Milling sand ( fly ash no need mill) and to make slurry

B, Lime: crushing - milling ( or to buy lime power directly)

C, Gypsum:to mill with sand or lime or input with fly ash then to make slurry directly.

2. Dry and wet Ball mill for lime and sand

3.Slurry batching: The prepared and stored raw materials to be used are metered, adjusted for temperature and concentration, and a small amount of dosing materials are metered on site, and then fed to the stirring equipment in turn according to the process requirements.

4. Pouring: In this process, the materials that are put into the mixer after the previous batching process are measured and adjusted if necessary, and the materials that meet the time, temperature, and consistency requirements of the process are made, then pouring into the mold. The pouring process is an important process that can form a good pore structure, and it constitutes the core

link of aerated production as the batching process.

5. Cutting of hongfa aac block production line : As the main equipment in the production process of aerated concrete block, the quality and cutting accuracy of aerated block cutting machine directly affect the quality of AAC block. JQF series of air filling block cutting machine of our company has the characteristics of high efficiency and high degree of automation .

1) Highly intelligent operation and management, PLC centralized control, with frequency converter to realize the whole cutting process automatic operation.

2) Hongfa cutting machine can not only produce AAC blocks, but also produce ALC panel, and cut the blocks and panels in six sides, so the quality of products is not affected by mould oil and mould deformation.

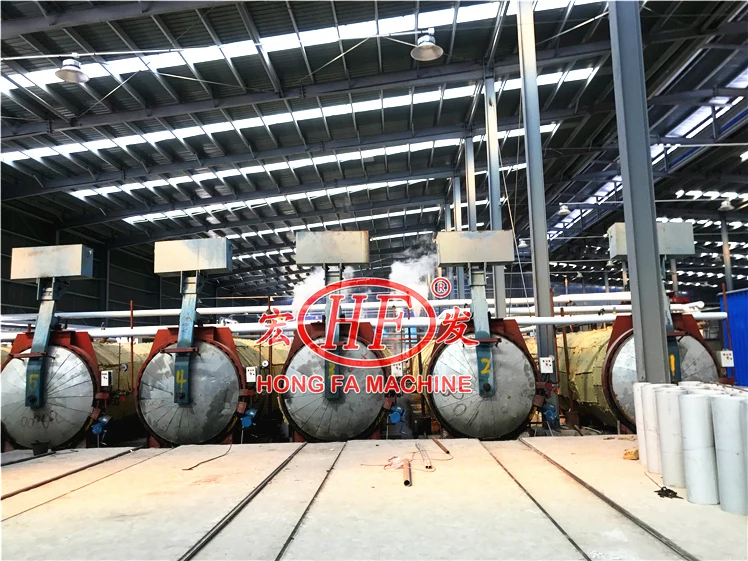

6.Autoclave curing for AAC block production line :

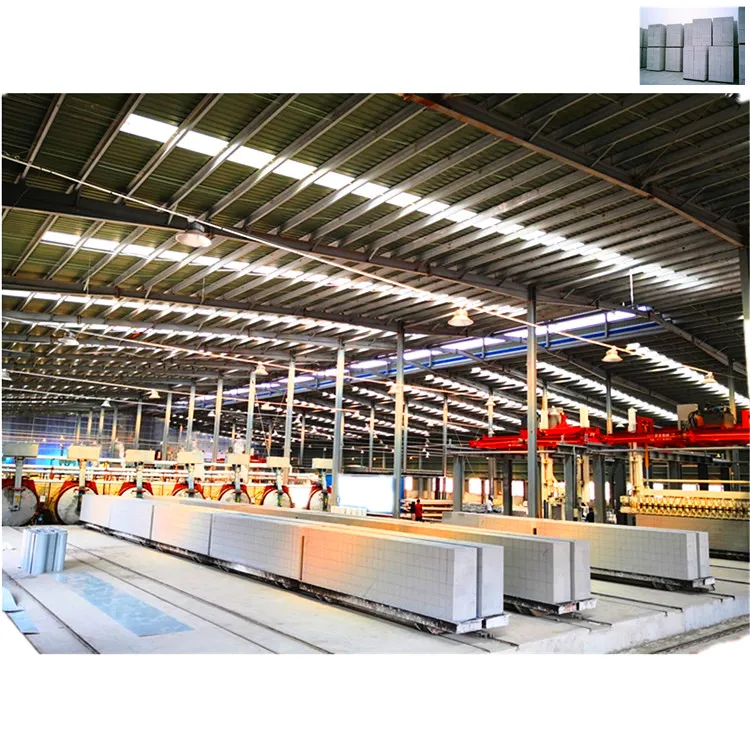

Hongfa Germany Ytong Autoclaved Aerated Concrete AAC block machine Plant AAC Block manufacturers AAC Block Production Line is running in our factory! Welcome to visit us !

Hongfa Germany Ytong Autoclaved Aerated Concrete AAC block machine Plant AAC Block manufacturers AAC Block Production Line , welcome to visit our factory to see the production line running!

Hongfa Germany Ytong Autoclaved Aerated Concrete AAC block machine Plant AAC

Block manufacturers AAC Block Production Line Introduction:

1.Our company has set up office in Vietnam,Indonesia,South Africa and sale service station in nanning guangxi province and will ensure the matericals rapid and timely service.

2.We have successfully exported and established more than 100 sets of AAC concrete production lines in overseas.So,we have many type of business model in

other countries,such as Indonesia,Myanmar,Iraq,Mongolia.You can pay a visitting to these countries and see our successful molds whenever you fell free.

3.Hongfa Machinery are the best manufactuer in producing aerated block and concrete block molding machine in China,as we Famous Trademark of China,and One of Top Ten Influential Brands in China Brick & Tile Industry.Please see the following Hongfa'Honor,and you will have a better undstanding to our company.

4.We have mature and rice experience to successfully help customers establish aerated concrete walls manufactuer.If you buy one set line of AAC from our company,we will give you a valued project report and detailed instrution.

QC Dept. will test our AAC block machine at least three times before shipping.

Hongfa Germany Ytong Autoclaved Aerated Concrete AAC block machine Plant AAC Block manufacturers AAC Block Production Line

Some of successful plants for Hongfa Germany Ytong Autoclaved Aerated Concrete AAC block machine Plant AAC Block manufacturers AAC Block Production Line

Advantages of the AAC block application

1. Sound proof

AAC wall has an excellent sound Transmission class (STC) ,rating of 44. Result: Virtually Soundproof Interiors

2. Thermal Insulation

It has highest thermal rating in the industry….R30! Thus provides well insulated interiors, keeping out warm air in summer and cold air in winters. AAC reduces Air conditioning cost by 30%.

3. Earthquake Resistant

Earthquake forces on structure are proportional to the weight of the building, hence AAC shows excellent resistant to earthquake forces. Regions of high seismic activity like Japan exclusively use AAC. It has been proven to withstand wind loads of category 5 tropical storms.

4. Floor Space Area

Use of thinner blocks (6" instead of 9" exterior walls) because of its excellent water barrier & insulation properties leads to an increase in floor space area between 3-5%.

5. Cost saving

Being lightweight AAC drastically reduces the dead weight of building, resulting into reduction in steel (up to 27%) and cement (up to 20%) structural cost saving. Being 8 times the size of a clay brick, AAC wall construction involves 1/3 the joints, thus an overall mortar saving up to 66%.

6. Fire Resistant

Best in class fire rating of 4 hours. The melting point of AAC is over 1600 ºc, more than twice the typical temperature in a building fire of 650 ºc.

7. Pest Resistant Termites hate AAC!

Being made of inorganic minerals, it does not promote growth of molds.

8. Water Barrier

Its structure does not allow for capillary action making it impervious to water. Its water barrier properties are further enhanced by adding silicone based additives.

Strength to weight ratio, higher than even M150 concrete and far exceeds the Indian Building code requirements.

9. Energy Efficient

Hongfa Group Established in 1990.

A leader developer& Manufacturer of Construction Material Machinery.

Main business Range & Products:

Lightweight Panel Production Line, AAC Block Production Line, Full Automatic Concrete Block Production Line, Artificial Quartz Plate Production Line, Concrete Pipe Machine, Concrete Tile Machine, Concrete pipe machine, Bidirectional Hydraulic Brick Maker, Mining Machinery, Concrete Batching plant, Stereo Parking Equipment, etc.

Hongfa Strengths

More than 30 years experience. 1500 employee (50+engineers)

2) Total 4 factories with 440,000M2 and annual sell above USD100 Million .

3) 10,000 customers and fulfillment to over 120 countries.

4) Continuous service and logistics system.

5) High quality products and competitive price.We hope we can cooperate with each other and establish a win-win business relationship.

Contact Information:

Foreign Trade Dept. : Emily Lee

Guangxi Hongfa Heavy Machinery Co., Ltd.

What's app:+86 15177094840

Wesite: www.gxhongfa.cn

Welcome to send me any inquiry of Hongfa Germany Ytong Autoclaved Aerated Concrete AAC block machine Plant AAC Block manufacturers AAC Block Production Line !

Похожие товары

HFD16/12-ZH-3N реле 12V 1A

Мини-камера видеонаблюдения Leksell с Wi-Fi IP-USB Full HD 720P P2P CCTV SD карта Облачное хранилище смарт-AI Обнаружение человека V

Puresci, ротор осушителя, активный силикагель, материал подходит для осушителя, производитель

Автомобильные детали под заказ, медные графит, Кнопка сцепления, тормозные колодки для грузовиков, детали сцепления

Оборудование для изготовления обуви на каблуках, промышленное оборудование для обуви

50 мм EPS Цемент бетон сэндвич стеновая панель изоляция полиуретан пенополистирол шлифовальная для плоских стен

INTL-CL152 7SBU16C 6PK авто компрессор переменного тока шкив сцепления для AUDI A4/A6/A8/S6/SKODA/VW 4B0260805B

Новые поступления

Новинки товаров от производителей по оптовым ценам