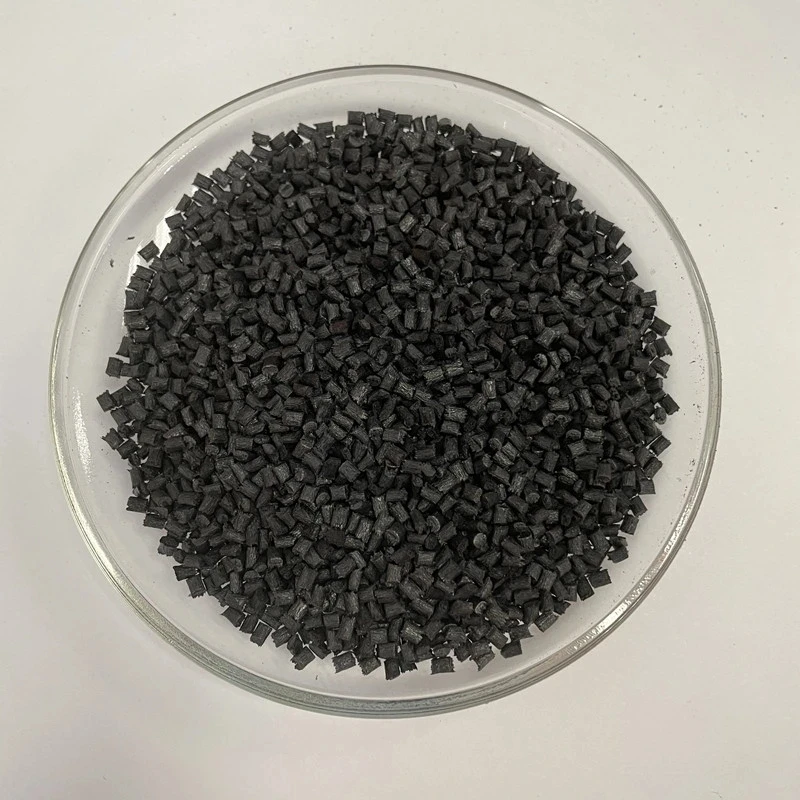

V0 класс полиамид с 15% стекловолоконным наполнителем PA6 GF15 пластиковая смола

- Категория: >>>

- Поставщик: Hebei Shengshi Plastic Sales Center

Сохранить в закладки 1600656091087:

Описание и отзывы

Характеристики

Products Description

PA6 Feature

It has the characteristics of thermoplastic, light weight, good toughness, good chemical resistance and durability, etc. It is

generally used in automobile parts, mechanical parts, electronic and electrical products, engineering accessories and other products.

generally used in automobile parts, mechanical parts, electronic and electrical products, engineering accessories and other products.

Product packaging

application

PA6

Our products are widely used in these industries, such as: household appliances, automobiles, electronic appliances, power tools, office equipment, etc.

Product Paramenters

Product Description | Applications | |||||||||

·10%,20%6 10% glass fiber reinforced,20% mineral filled PA6 | · Injection molding | |||||||||

· Excellent heat stability | · Good mechanical properties balance | |||||||||

Properties | Test Method | Test Condition | Unit | Typical Values | ||||||

Physical properties | ||||||||||

Specific Gravity | ISO 1183 | 23ºC | g/cm3 | 1.35 | ||||||

Ash | ISO 3451 | 800ºC,30min | % | 30 | ||||||

Mechanical properties | ||||||||||

Tensile Strength | ISO 527 | 50mm/min | MPa | 125 | ||||||

Elongation at Break | ISO 527 | 50mm/min | % | 2.5 | ||||||

Flexural Modulus | ISO 178 | 2mm/min | MPa | 8500 | ||||||

Izod Notched Impact Strength | ISO 180 | 23ºC | kJ/m2 | 9 | ||||||

Thermal properties | ||||||||||

Heat deflection temperature | ISO 75 | 1.80MPa | C | 185 | ||||||

Melting Point | DSC | - | C | 222 | ||||||

Other properties | ||||||||||

Mold Shrinkage | internal test method | 48 hours after tool | % | 0.3-0.5 | ||||||

Flammability | TL1010 | - | mm/min | 39 | ||||||

Company Profile

Hebei Shengshi Plastic Sales Center is a distribution center affiliated to SINOPEC, selling raw materials at a lower price.

The company has warehouses in Tianjin, Ningbo and Guangzhou port, and the goods are distributed nearby. The products are exported to Southeast Asia, North America, South America, Europe, Africa and other 50 countries all over the world, with excellent quality, stable supply of goods and competitive price.

The company has warehouses in Tianjin, Ningbo and Guangzhou port, and the goods are distributed nearby. The products are exported to Southeast Asia, North America, South America, Europe, Africa and other 50 countries all over the world, with excellent quality, stable supply of goods and competitive price.

Transportation

FAQ

Q1. About payment terms

A: We’d like to use T/T, visa, Paypal as the terms of payment About L/C, D/A, D/P terms can communicate.

Q2. About Trade Term

A: We accept FOB/CIF/EXW/CNF as trade term.

Q3. Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight

Q4. How about your delivery time?

A: Generally it is 7-14days, if we have stock. If not, maybe need 15-20 days to arrange the shipping.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

A: We’d like to use T/T, visa, Paypal as the terms of payment About L/C, D/A, D/P terms can communicate.

Q2. About Trade Term

A: We accept FOB/CIF/EXW/CNF as trade term.

Q3. Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight

Q4. How about your delivery time?

A: Generally it is 7-14days, if we have stock. If not, maybe need 15-20 days to arrange the shipping.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Похожие товары

25 шт. черные треугольные D-образные кольца пилообразный зуб фото рамка вешалка художественная Работа картина маслом зеркальная пила зубной крючок с винтом 6 типов

ГТ DMTG прецизионный токарный станок с ЧПУ Ck6140 горизонтальный токарный станок с плоской кроватью

80 000,00 $

Пользовательский пустой белый ПВХ контактный чип бизнес-отель ID RFID-карта для системы контроля доступа

Внутренний диаметр 6 8 10 12 14 16 19 25 32 мм экструдированный силиконовый шланг, оранжевый внутри и синий снаружи

США 12 унций 16 унций сублимационный прозрачный матовый цвет холодное пиво Вино кофе стеклянный стакан бутылка стеклянная чашка с крышкой

0,85 $ - 1,85 $

dualie дети пластиковые тачки

Мужской незаметный антиперспирант Rexona для черного и белого цвета, спрей-дезодорант-150 мл

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $