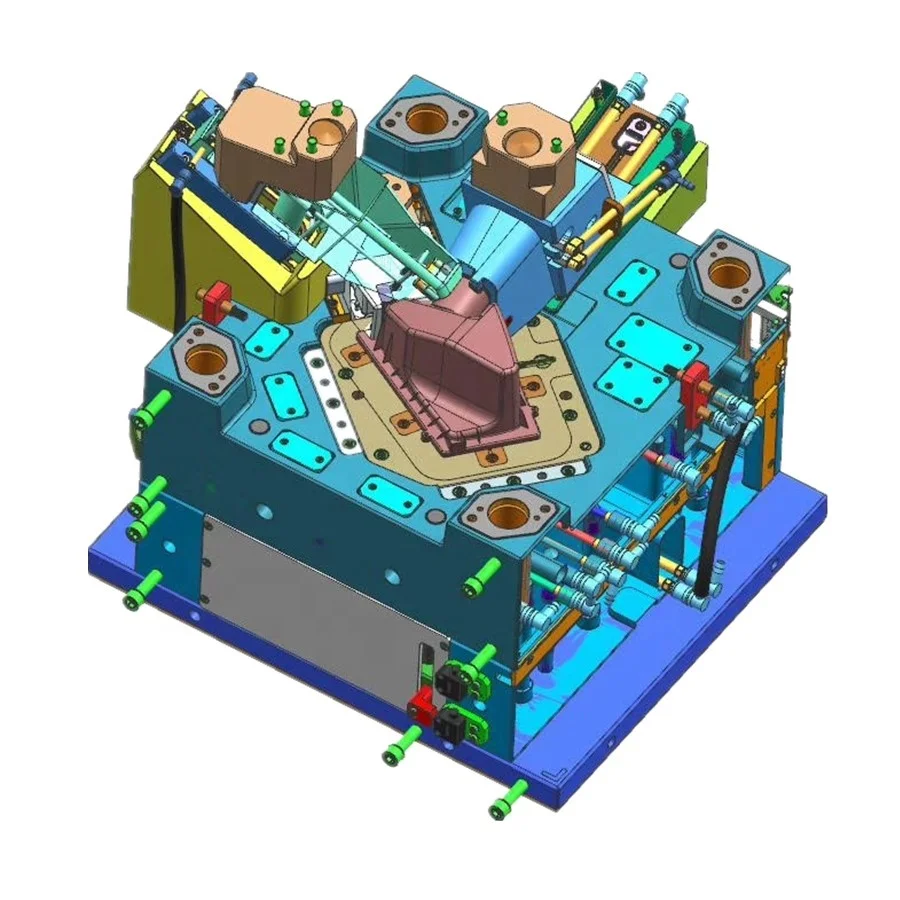

Изготовленный на заказ Abs Pp Pc Tpe Tpr Пластиковая форма дизайн DFM профиль литья под давлением Пластиковые формы завод

- Категория: >>>

- Поставщик: Dongguan Cents Precision Manufacturing Co. Ltd

Сохранить в закладки 1600658814752:

Описание и отзывы

Характеристики

What We Do: | ||||||||

1). | We make Export Mold / Mould; | |||||||

2). | We do Injection Molding Service; | |||||||

3). | Assembly and Packing Service | |||||||

Information for Mold and Parts:

Mould Information | Product Name | Plastic Injection Mould | ||

Mould Standard | LKM/HASCO/FUTABA/DME according to buyer's requirement | |||

Mold Type | Injection Mould | |||

Sprue Gate | Pin-Point Gate, Submarince Gate... | |||

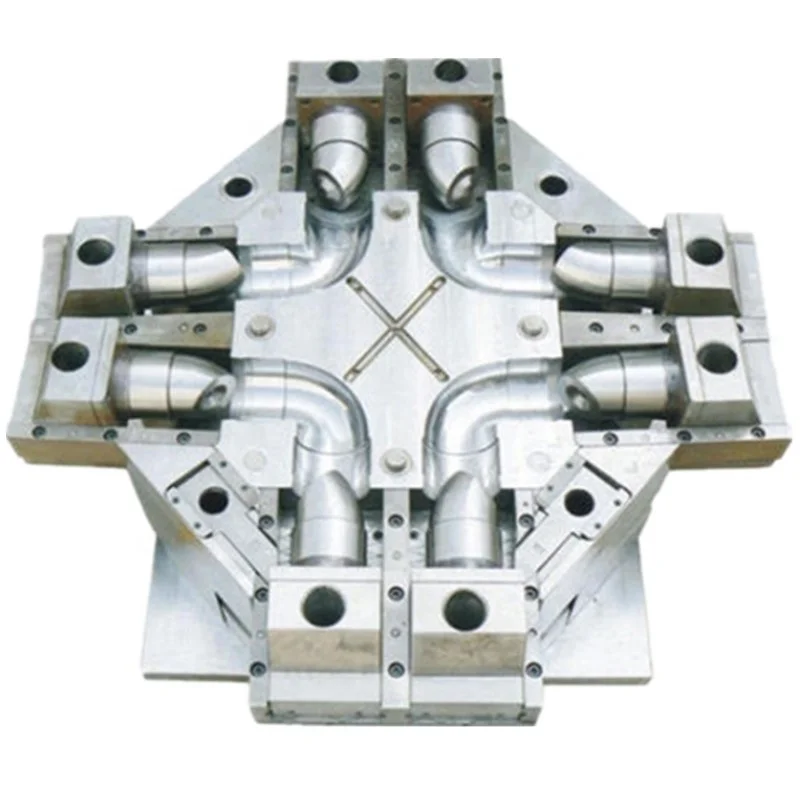

Mold Cavity | Single or multi cavity | |||

Runner Form | Cold Runner or hot runner according to product type and cavity | |||

Mould Material | NAK80, S136, 2344,2316, 718, P20... | |||

Mould life | 300000-800000shots | |||

Mould Maintenace | Keep it well maintened | |||

Plastic Part | Material | ABS, PP, PC, ABS+PC, PA66, PTFE, PEI... according to buyer's requirement | ||

Injection machine | 30ton, 100ton, 160ton, 450ton, 500 ton, 800ton... | |||

File Support | 3D drawing in Step, UG... | |||

Injection time | According to cavity, product constructure | |||

Injection system | Automatic ejection, Robert Jig system.. | |||

Custom Abs Pp Pc Tpe Tpr Plastic Mould Design DFM Profile Injection Mold Plastic Moulds Factory

Company Profile

Our Main Features:

1). We Do the Whole Mould Making Processes in House to control better Cost,Delivery and Quality:

Grinding-Drilling-EDM-WEDM-CNC Machining-Polishing-Mould Testing...

Grinding-Drilling-EDM-WEDM-CNC Machining-Polishing-Mould Testing...

imd / iml parts Injection molding | |

overmould parts Injection molding | |

two colors parts Injection Molding |

Cents was certified with ISO9001 quality system by the International Standards Authority(ISA) in 2008.

All the employees took part in the training. The quality responsibility for each department was clarified, and the management procedure was specified.Besides,the coordination between the input and output was also defined. Quality manual and program files were compiled. In the future production process, we will insist on continuous improvement to the the key weak link.

Quality Control System

It`s a long process for each product from material purchasing to the final delivery. If an error can not be identified timely, the

delivery will get delay, and cause waste on human labor and material etc. To ensure customer get the qualify products,

Cents QC Procedure

1. Part mold draft analysis

2. Mold design control

3. Steel hardness inspection

4. Dimension inspection of electrode ,cavity and core

5. Mold trial report and inspection report

6. PPAP

7. Shipment inspection

Quality Control System

It`s a long process for each product from material purchasing to the final delivery. If an error can not be identified timely, the

delivery will get delay, and cause waste on human labor and material etc. To ensure customer get the qualify products,

Cents QC Procedure

1. Part mold draft analysis

2. Mold design control

3. Steel hardness inspection

4. Dimension inspection of electrode ,cavity and core

5. Mold trial report and inspection report

6. PPAP

7. Shipment inspection

Relative Products

We make all kinds of Customize Plastic Parts/Case/Enclosure

Mainly covering to:

1) Auto parts mold and molding ;

1) Auto parts mold and molding ;

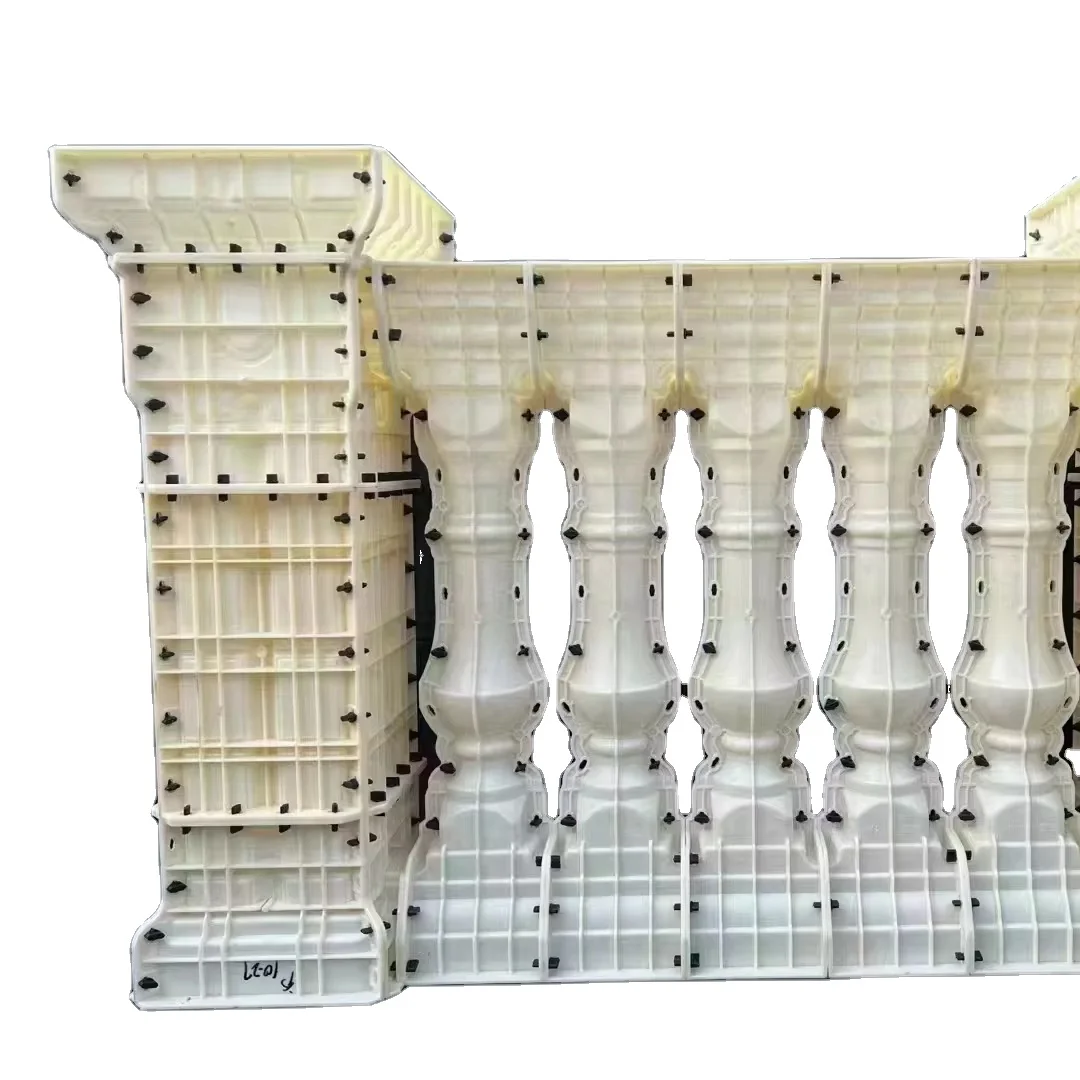

2) Consumer Electronics Enclosures mold and molding;

3) Household Produts Case mold and molding;

4) Industrial Tool Parts mould and moulding;

5) Cosmetic Tube or Container mould and moulding...Etc

One of our big advantage is making the IMD / IML Injection mold molding parts

1. 3D file or Real Sample for your products; 2. Material you require; 3. Surface treatment requirement

So our above price is only for your reference. We can quote exact price according to:

1. 3D file or Real Sample for your products; 2. Material you require; 3. Surface treatment requirement

Our Customer

Stable and Double Win Cooperation Is the Goal We Have Been Pursuing.

If you have any new Custom Plastic Parts / Enclosure / Case / Frame to be developed,please feel free to:

i). Send us 3d drawing in stp,sign NDA is acceptable if necessary;

ii). Let us know what material to be used for the part;

iii). Better to tell us the yearly qty plan,so we could have better mold design suggestion to you.

i). Send us 3d drawing in stp,sign NDA is acceptable if necessary;

ii). Let us know what material to be used for the part;

iii). Better to tell us the yearly qty plan,so we could have better mold design suggestion to you.

Product packaging

Firstly assembling and clearing mold well, and then paint anti-rust fog or grease on mold, then cover with thin film and place it into a stable wooden case.

Product Shipping

Firstly,to wrap each part up with semi-transparent thin foam and put it into plastic bag, the second step is place them into

cartons with thin sponge plates to prevent scratches.

FAQ

Q: How many molds could you make every month?

A: About 120 sets

A: About 120 sets

Q: How about the largest mold you ever made?

A: 1800*1400*950mm

Q: How about the tolerance?

A: Mold tolerance 0.02mm, Product 0.02mm

Q: Could you make double color injection mold

A: YES

Q: What do you need for the quotation?

A: We need 2D product drawing&3D file, or specific sample with detailed explanation and mold sepcification

Q: How about the steel you usually use?

A: We only use standard components form LKM,DAIDO, HASCO, DME

Q: What is your turnaround time for injection mold buiilding?

A: Usually 3-5 weeks, it also depends on mold zide and structure complexity. We can overwork for your urgent project to shorten the delivery.

A: 1800*1400*950mm

Q: How about the tolerance?

A: Mold tolerance 0.02mm, Product 0.02mm

Q: Could you make double color injection mold

A: YES

Q: What do you need for the quotation?

A: We need 2D product drawing&3D file, or specific sample with detailed explanation and mold sepcification

Q: How about the steel you usually use?

A: We only use standard components form LKM,DAIDO, HASCO, DME

Q: What is your turnaround time for injection mold buiilding?

A: Usually 3-5 weeks, it also depends on mold zide and structure complexity. We can overwork for your urgent project to shorten the delivery.

Похожие товары

EPDM резиновый силиконовый компрессионный формовочный каучук TPE поверх пресс-формы для литья под давлением и компрессионная пластиковая часть

10,79 ₽ - 107,90 ₽

Дешевая пластиковая пресс-форма для литья под давлением, пресс-форма для литья под давлением, пластиковая резиновая форма

376,57 ₽ - 527,63 ₽

Шэньчжэнь пластик ТПЭ мягкая резина/силикон литье под давлением два выстрела Молдинг

Шэньчжэнь ABS электронные продукты, Пластиковая форма для прессования под давлением

11,87 ₽ - 22,66 ₽

ПВХ труба/профиль WPC/формовочная доска для экструзионной линии

Китай высокое качество формы для бетонных балясин для продажи

Сотовая перегородка, экструзионные молдинги, инструменты для ограждения дороги, балясины

539 489,00 ₽ - 1 942 160,40 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $