Пластиковая сборная машина оборудование для массового производства Рычажная рама автоматическая сборка

- Категория: Other Machinery & Industrial Equipment >>>

- Поставщик: Shanghai Suyu Electronics Co. Ltd.

Сохранить в закладки 1600677374889:

Описание и отзывы

Характеристики

Product Show

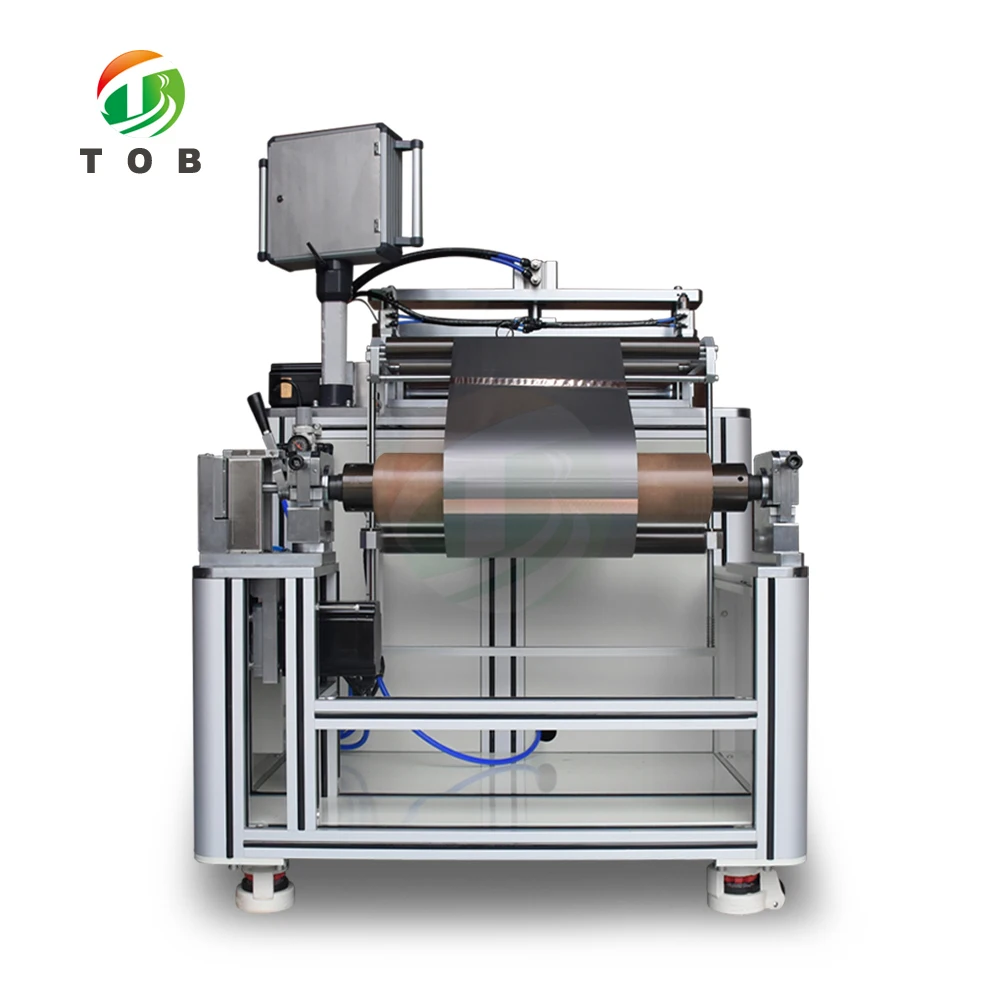

Automated Assembly Machines

Working environment | Working environment temperature: | - 12 ℃ ≤ temperature ≤ 45 ℃. |

environment humidity: | 20-90% under normal temperature. | |

Working environment air: | no corrosivity,Flammable and explosive gas. | |

Equipment location requirements: | ventilation around, no barrier and heat source within 1m. | |

Energy requirements | Power supply: | AC220V+/- 5% 50/60Hz |

Air supply: | flow ≥ 1M3/MIN0.4MPa ≤ pressure ≤ 0.8MPa | |

special grease for mechanical transmission, which shall be filled regularly according to maintenance requirements. |

1.Equipment name: Lever rack automatic assembly equipment.

2.Device Model: SY-4T/A.

3.Equipment function: mainly used for lever frame, spring, thread block, lever, assembly and so on.

4.Production beat: 6s/pcs (the working cycle of the equipment, the specific time shall be subject to the actual work) .

2.Device Model: SY-4T/A.

3.Equipment function: mainly used for lever frame, spring, thread block, lever, assembly and so on.

4.Production beat: 6s/pcs (the working cycle of the equipment, the specific time shall be subject to the actual work) .

5. Equipment energy consumption: 5.5KVA

6. Equipment capacity: 2 shifts per day and 10 hours per shift.

7.Operator: 1 person.

6. Equipment capacity: 2 shifts per day and 10 hours per shift.

7.Operator: 1 person.

The first station The second station The third station The fourth station

Accessories Final good

Our company

SUYUSONIC

Founded in 2005, Shanghai Suyu Electronic Co., Ltd. is a professional plastic welding equipment and tooling manufacturer integrating R & D, production, sales and service.

Our products include ultrasonic welding machine, hot plate welding machine, rotary friction welding machine, hot riveting welding machine, infrared wire welding machine, laser welding machine and automatic assembly welding detection line.

We are located in Shanghai with convenient transportation. We have our own manufacturing plant and four subsidiaries in China.We have established a branch office in India and a service department in Brazil.Our company is committed to strict quality control and considerate customer service.

Successful Project

Oil mist separator/Cylinder cover assembly/Testing line

National Ⅵ canister assembly and testing line

Intake manifold/Cylinder cover assembly/Inspection line

Net pipe/Dirty pipe/Presure pipe

Assembly welding inspection workstation

Assembly welding inspection workstation

FAQ

1. Who are we?

We are based in Shanghai, China, start from 2005,sell to Domestic Market,Southeast Asia,South America.

There are total about 101-200 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3.What can you buy from us?

Automatic Assembly and Welding Detection Line,Ultrasonic Welding Machine,Filter Paper Welding Machine,Hot Plate Welding Machine,Spin Friction Welding Machine.

4. Why should you buy from us not from other suppliers?

Our company has rich experience in the design, manufacture and commissioning of "Plastic Welding" and "Industrial Automated Assembling and Testing" systems.Such as hot plate welding, ultrasonic welding, infrared welding and new technologies and so on.

5. What information do you need to provide to receive a quote?

After the initial discussion to determine we are a good fit for your requirement, we will then ask you to provide us the component specifications, samples/drawings, production speeds and design specifications.

We are based in Shanghai, China, start from 2005,sell to Domestic Market,Southeast Asia,South America.

There are total about 101-200 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3.What can you buy from us?

Automatic Assembly and Welding Detection Line,Ultrasonic Welding Machine,Filter Paper Welding Machine,Hot Plate Welding Machine,Spin Friction Welding Machine.

4. Why should you buy from us not from other suppliers?

Our company has rich experience in the design, manufacture and commissioning of "Plastic Welding" and "Industrial Automated Assembling and Testing" systems.Such as hot plate welding, ultrasonic welding, infrared welding and new technologies and so on.

5. What information do you need to provide to receive a quote?

After the initial discussion to determine we are a good fit for your requirement, we will then ask you to provide us the component specifications, samples/drawings, production speeds and design specifications.

Похожие товары

Школьная машина для изготовления мела цена ручная литья в

1 860,00 $ - 2 250,00 $

Машина для сборки крышки

Полуавтоматические ролики Eurotech для мягких колес сборное оборудование lang 4 2 дюйма установка машины в европейском

9 600,00 $ - 9 800,00 $

Промышленный пластиковый поворотный миксер цветной блендер для пластиковых

1 200,00 $ - 1 400,00 $

Полировальный станок для iPhone 13 14 шлифовальный с

1 800,00 $ - 1 850,00 $

Refox APM-20B APM-40B APM-80 для шлифовки и полировки стекла машина iPhone мобильный телефон-часы ЖК-экрана с защитой от царапин удаления

Машина для ламинирования oca YYD на заказ ЖК-экран вакуумная машина ремонта мобильных телефонов и

98,50 $ - 107,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $

Оригинальная популярная клавиатура для рабочего места Genos2 с 76 клавишами

200 $

Умный цифровой электронный ручной инфракрасный лазерный термометр для ветеринарного и медицинского мониторинга человека

5-10 $

Цифровой инфракрасный лазерный термометр для взрослых

5,90-6,70 $

Командная версия 24-скоростной ультралегкий карбоновый шоссейный велосипед Гоночная рама и комплект колес

Четырехцилиндровый двигатель CA6110/125G5 части клапана 1007011-A013-0000 1007016-A013-0000

0,50 $

55203781 46740344 55181201 55266538 зубчатый шкив коленчатого вала для FIAT 500 BRAVA BRAVO DOBLO PANDA PUNT0

3-3,70 $