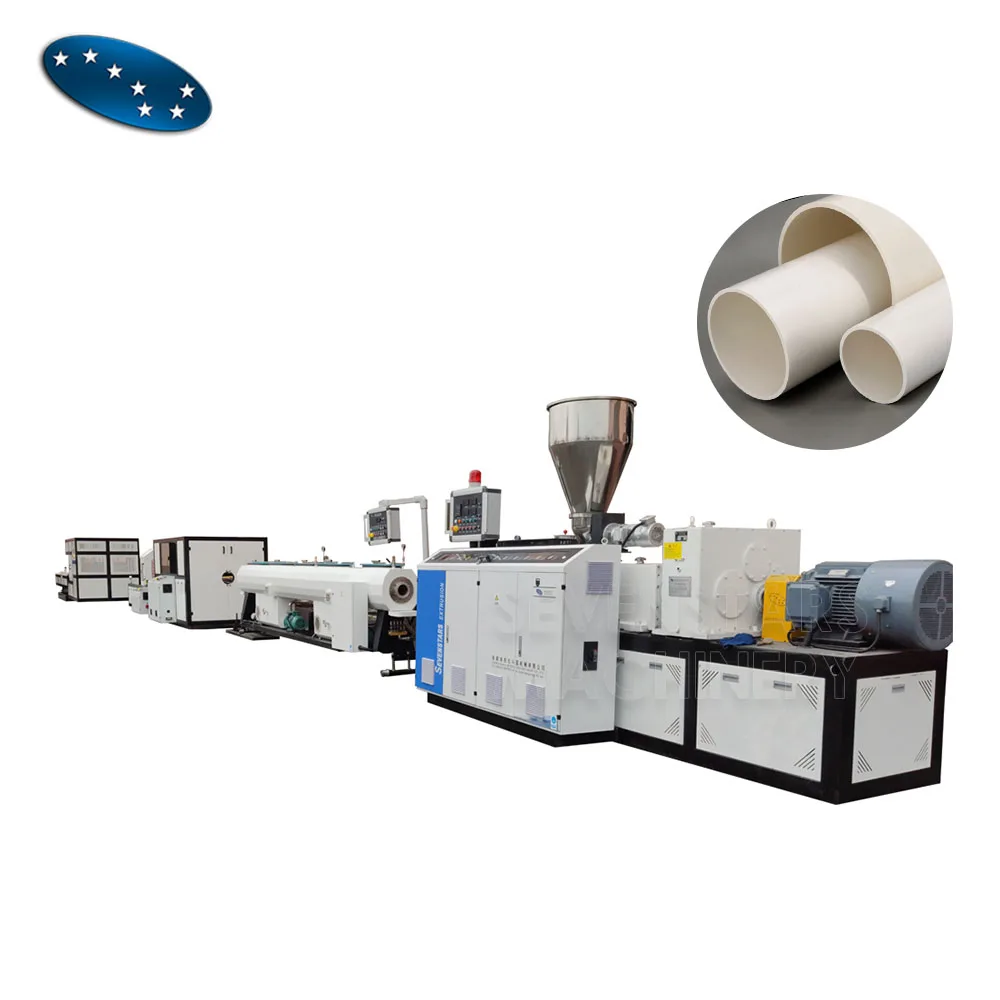

Машина для производства пластиковых ПВХ труб конический двухшнековый экструдер по хорошей

- Категория: >>>

- Поставщик: Zhangjiagang Sevenstars Machinery Co. Ltd.

Сохранить в закладки 1600686245651:

Описание и отзывы

Характеристики

PVC CPVC UPVC pipe production line / PVC extruder / PVC pipe extrusion machine

Φ20-Φ630 series PVC pipe extrusion machine line is mainly used in the manufacture of plastic PVC pipes with various diameters and wall thickness used in the industries such as agricultural and constructional plumbing,cable laying etc. This line is composed of conical twin screw extruder,Vacuum calibration tank,haul off,motors,cutter and stacker etc. The extruder and haul off methods are two-claw,three-claw four-claw,six-claw,eight-claw,ten-claw,twelve claw etc. You may choose saw blade cutting type or planetary cutting type. It is aditionaly attached with length counter and intensifying device. This line with reliable performance and high production eficiency. Our company can also manufacture special pipe production lines,e.g. spiral silencing pipe and core foaming pipe according to your requirements.

PVC pipe making machine performance

1.Replacement molds can produce pipes with different diameters.

2.With a set of molds to produce two or four tubes at the same time.Increased production efficiency.

3.More cost-effective production line.

4.Greatly saving the use of the factory space.

5.High energy efficiency.Just a set of power systems.

6.Can significantly reduce the number of operators.

7.Simple operation.

1.2 Quality Screw and Barrel

1.3 Air Cooled Ceramic Heater

1.4 High Quality Gearbox and Distribution Box

1.5 Better Cooling of Gearbox1.6 Advanced Vacuum System

1.7 Easy Cable Connection

2.2 Die Head Rotary Device

2.3 CNC Processing

2.4 High Quality Material

mirror polishing and chroming to ensure material flow smoothly.

Die head is modular design, easy for changing pipe sizes, assembling, dismantle and maintenance. we can also produce single layer or multi-layer pipe.

3.2 Better Support for Pipe

3.3 Silencer

3.4 Pressure Relief Valve

3.6 Water, Gas Separator

3.7 Full Automatic Water Control

3.8 Centralized Drainage Device

in short length, to ensure very strong cooling and vacuum function. As calibrator is placed in the front of first chamber and pipe

shape is formed mainly by calibrator, this design can ensure quick and better forming and cooling of pipe.

5.2 Advanced Hydraulic System

5.3 Dust Collection System

Cutter controlled by Siemens PLC with chamfering function, working together with haul off unit to have precise cutting. Customer

can set the length of pipe they want to cut.

Model/Item | Pipe range | Extruder | Max output | Max speed | Total power |

PVC-50*2 | 16-50mm | SJSZ65/132 | 250kg/h | 10 m/min | 85 kw |

PVC-63 | 16-63mm | SJSZ51/105 | 150 kg/h | 10 m/min | 60 kw |

PVC-110 | 50-110mm | SJSZ55/110 | 180 kg/h | 10 m/min | 70 kw |

PVC-160 | 63-160mm | SJSZ65/132 | 300 kg/h | 5 m/min | 90 kw |

PVC-250 | 110-250mm | SJSZ80/156 | 400 kg/h | 3.5 m/min | 120 kw |

PVC-315 | 160-315mm | SJSZ80/156 | 400 kg/h | 3 m/min | 160 kw |

PVC-450 | 250-450mm | SJSZ92/188 | 700 kg/h | 1.5 m/min | 200 kw |

PVC-630 | 315-630mm | SJSZ92/188 | 700 kg/h | 0.9 m/min | 230 kw |

Why choose us?

1.Low cost

All the machine ,we make it ourself to reduce the cost of our customer.

2.Genuine product with excellent quality

We choose our material very strict.

All the material come to our factory must pass the quality test

Substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4.Quick delivery

The company provide just in time delivery with its streamlined supply chain.

5.Cost saving

Se take strong attention to every detail in the manufacturing process.

The quality control in our factory is very strict.

All defective semi-manufactures must be treated again or reject.

All the machine must be checked out ,then delivered to our customer.

All about that pushing up the price,but get good quality machine.

What we want to do is give our customer a good quality product with stable working and long lived.

Похожие товары

40 унций чашки для кофейного автомобиля с ручкой изолированный стакан из нержавеющей стали вакуумные колбы портативные бутылки для воды

Микро-подушка из спандекса с бусинами/U-образная подушка для шеи из спандекса, дорожная подушка из спандекса

Планетарный миксер SICOMA Pan типа MPC, модель № MPC1875/1250

Новый продукт ручной работы с жемчужинами с блестками и бисером кружевной ткани Французский вышитый тюль ткань Нью-Йорк Оптовая ткань кружева HY0971-1

С высоким уровнем сережки из высококачественного гипоаллергенного сплава с прошивкой, прочные, износостойкий, с волнообразным краем; zapatos de seguridad труда Рабочая защитная обувь

Современный минималистичный эргономичный и удобный сетчатый офисный стул с бабочкой для конференц-зала

Камера заднего вида 1000TVL для автомобилей

Новые поступления

Новинки товаров от производителей по оптовым ценам