Полиэтиленовая полипропиленовая Труба 20 63 мм многослойная линия по производству экструдеров/пластиковые экструдеры

- Категория: >>>

- Поставщик: Zhangjiagang Huade Machinery Technology Co. Ltd.

Сохранить в закладки 1600706335095:

Описание и отзывы

Характеристики

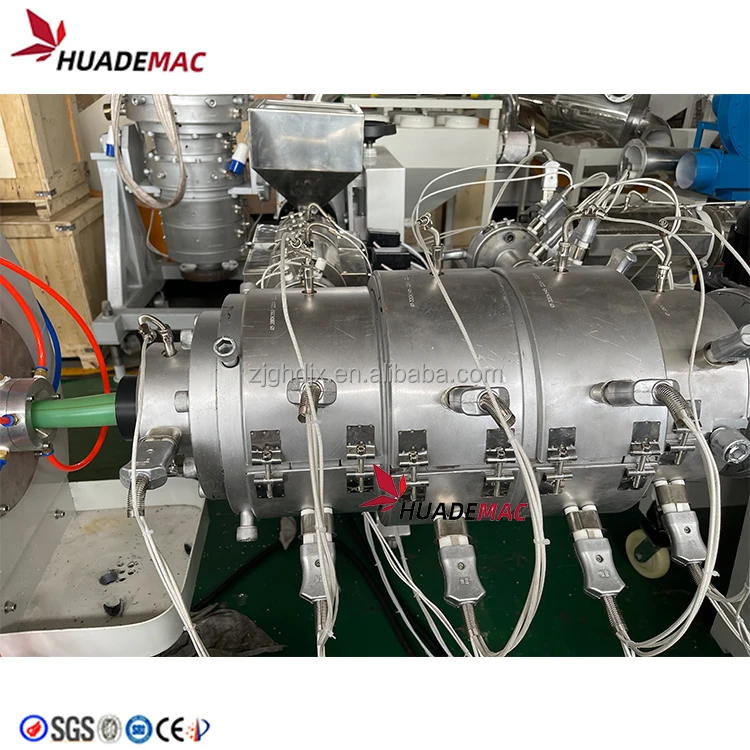

PE PPR pipe 20-63mm multi-layer extruder production line/plastic extruders

PE PPR pipe 20-63mm multi-layer extruder production line/plastic extruders

Product Application

The company inducts the moderm management idea and uses the strict quality assurance system. The thinking providing user the high-quality service and meeting the user biggest need is own duty. It strengthens in the production process to each kind of stage product examination and the experiment to guaranteed customer's satisfaction.

The company inducts the moderm management idea and uses the strict quality assurance system. The thinking providing user the high-quality service and meeting the user biggest need is own duty. It strengthens in the production process to each kind of stage product examination and the experiment to guaranteed customer's satisfaction.

PE PPR pipe 20-63mm multi-layer extruder production line/plastic extruders list

No. | Machine | Qty. |

1 | AL300 Vacuum Feeder | 1 pc |

2 | STG-U80 Hopper Dryer | 1 pc |

3 | SJ65/33 Single Screw Extruder | 1 pc |

4 | SJ45/30 Single Screw Extruder with Feeder and Dryer | 3 pcs |

5 | SJ25/25 Co-Extruder-Color Line | 1 pc |

6 | Die head & Mould (20/25/32/40/50/63mm) | 1 set |

7 | Vacuum Calibration Tank | 1 pc |

8 | Water Spray Cooling Tank | 1 pc |

9 | 2 Caterpillar Haul-Off | 1 pc |

10 | Dust-free Cutter | 1 pc |

11 | Stacker | 1 pc |

12 | Hot Transfer Machine | 2 pcs |

13 | 100kg Mixer | 4 pcs |

Main Technical Features

PP-R pipe extrusion line is developed by Huade based on European advanced technology and experience of the plastic machinery for many years. Advanced design, reasonable structure, high reliablity, high degree automation of the complete line.

PP-R pipe extrusion line is developed by Huade based on European advanced technology and experience of the plastic machinery for many years. Advanced design, reasonable structure, high reliablity, high degree automation of the complete line.

PE PPR pipe 20-63mm multi-layer extruder production line/plastic extruders photos

Single screw extruder

Drive motor: Siemens Beide motor

Inverter: ABB

Temperature control: Omron

Contactor: Siemens

For 20-63mm three layer pipe machine, if you have specific requirement for each layer percentage, we suggest you use three

extruder co-extrusion, otherwise 2 sets extruder co-extrusion is enough.

Inverter: ABB

Temperature control: Omron

Contactor: Siemens

For 20-63mm three layer pipe machine, if you have specific requirement for each layer percentage, we suggest you use three

extruder co-extrusion, otherwise 2 sets extruder co-extrusion is enough.

Material: 40Cr

Calibrator: Stainless steel

It will be much better if you can tell us the specific pipe size(pipe diameter & pipe thickness or pressure) you want to produce,

then we can suggest you the most suitable machine based on your requirements.

Calibrator: Stainless steel

It will be much better if you can tell us the specific pipe size(pipe diameter & pipe thickness or pressure) you want to produce,

then we can suggest you the most suitable machine based on your requirements.

Material: Stainless steel

Tank Movement : Forth and back by motor driven Up and down by manual adjust

Tank Movement : Forth and back by motor driven Up and down by manual adjust

Material: Stainless steel

Length: 6m or customized

Length: 6m or customized

2 Caterpillar Haul-Off

Haul Off Maximum Pipe Diameter:Φ63mm

Useful haul-off length:1300mm

Haul Off Speed: 1-10m/min

Haul Off Motor Power:1.5kwX2pcs

Hold Pipe Mode: By Cylinder

Haul Off Motor Mode: Motor With Inventor From ABB

Useful haul-off length:1300mm

Haul Off Speed: 1-10m/min

Haul Off Motor Power:1.5kwX2pcs

Hold Pipe Mode: By Cylinder

Haul Off Motor Mode: Motor With Inventor From ABB

Cutting Machine

Cutting Saw: Adopt Alloy Steel Saw

Machine Type: No dust cutting machine

This type cutting machine can reduce the dust in your factory, and with lower norise.

This type cutting machine can reduce the dust in your factory, and with lower norise.

Stacker

Laying Board Material: 1.5mm Stainless Steel Board

Stacking Mode: Stacking by Gas Cylinder, adopt Limited Switch Send out Cutting Signal

Stacking Mode: Stacking by Gas Cylinder, adopt Limited Switch Send out Cutting Signal

Related Products

PE PPR pipe 20-63mm multi-layer extruder production line/plastic extruders exhibition

Certifications

Похожие товары

Высокая точность C7 grade32mm мяч screw3205 HIWIN шариковый винт R32-5T4-FSI

Хорошее качество Универсальные пластиковые автомобильные аксессуары Автомобильная кожаная консоль коробка Универсальный подлокотник для автомобильного сиденья

6,00 $ - 6,50 $

HIP6008CB-T бак широтно-модулятор (ШИМ)

Большая доза розлива жидкости и скручивания защиты от кражи, механическая группа, фармацевтическая машина для розлива

25 000,00 $

20 шт., водонепроницаемый кожаный портсигар

0,65 $ - 0,79 $

Полноценная гусеничная дробильная установка для карьера, передвижная ударная Дробилка для камня с фидером и ленточным конвейером

110 000,00 $ - 145 000,00 $

Eyika латунный позолоченный бразильский браслет из сплава камней CZ регулируемый браслет с конским глазом Рубином женские ювелирные изделия оптом

Новые поступления

Новинки товаров от производителей по оптовым ценам

Умный цифровой электронный ручной инфракрасный лазерный термометр для ветеринарного и медицинского мониторинга человека

5-10 $

Цифровой инфракрасный лазерный термометр для взрослых

5,90-6,70 $

Командная версия 24-скоростной ультралегкий карбоновый шоссейный велосипед Гоночная рама и комплект колес

Четырехцилиндровый двигатель CA6110/125G5 части клапана 1007011-A013-0000 1007016-A013-0000

0,50 $

55203781 46740344 55181201 55266538 зубчатый шкив коленчатого вала для FIAT 500 BRAVA BRAVO DOBLO PANDA PUNT0

3-3,70 $

Оптовая продажа 100% Рафинированное Масло из семян подсолнечника малазия масло для приготовления пищи

GY031 металлическая рамка пользовательских игровых сидений Sim гоночные игровые сиденья симулятор вождения кабины для Xbox 360 Logitech G25 G27 G29 G920

88-143 $

Роскошные пользовательские островные стулья современные кухонные с выдвижными ящиками и раковиной кухонный шкаф U-образной формы из нержавеющей стали

160-180 $