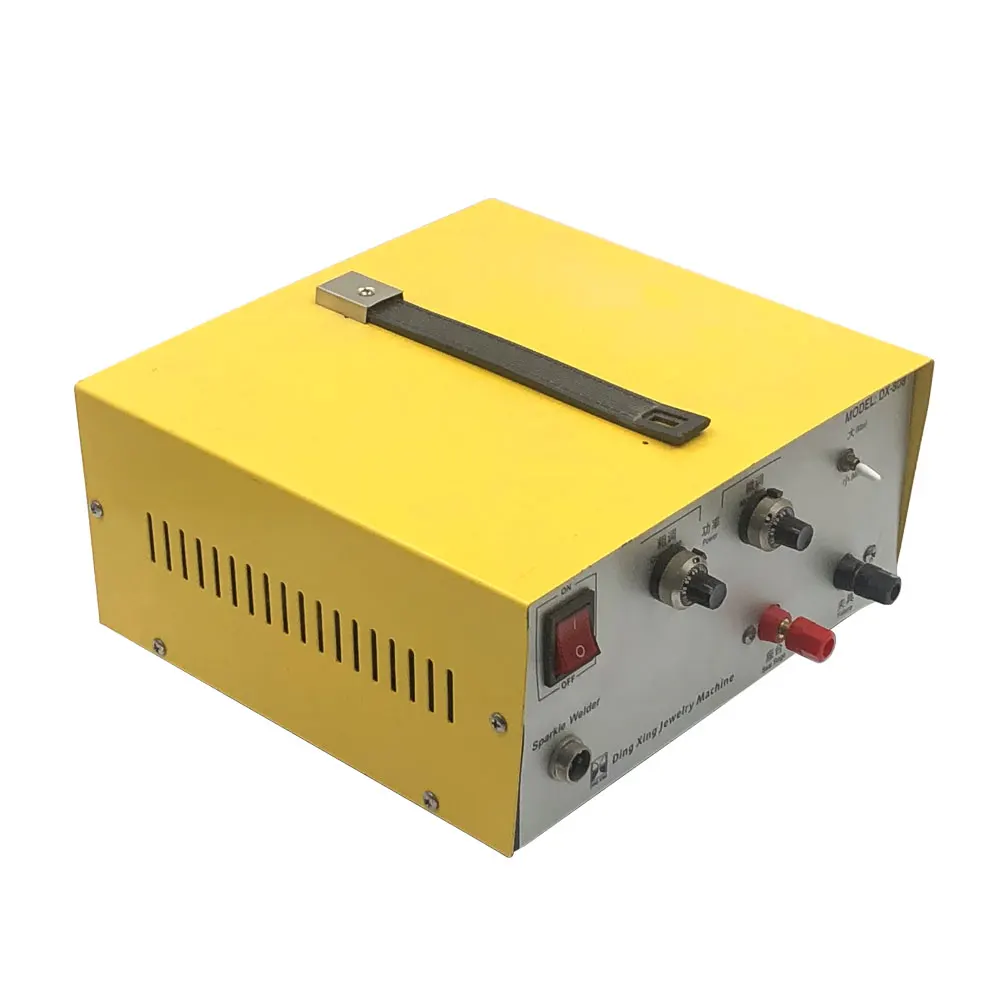

Аппарат для точечной сварки 80 А

- Категория: Spot Welders >>>

- Поставщик: Xiamen Meidianou Trade Co. Ltd.Xiamen Ltd.

Сохранить в закладки 1600710540100:

Описание и отзывы

Характеристики

| After Warranty Service | Video technical support |

| Certification | CE |

| Showroom Location | None |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Not Available |

| Marketing Type | Hot Product 2019 |

| Warranty of core components | 1 Year |

| Core Components | PLC |

| Condition | New |

| Warranty | 1 Year |

| Key Selling Points | Low Maintenance Cost |

| Place of Origin | Fujian,China |

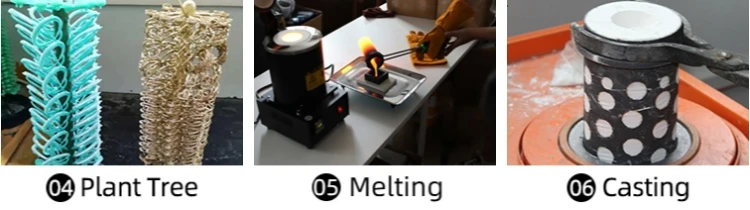

| Applicable Industries | Jewelry making tools |

| Welding Range | 0.5-2.0MM |

| Dimensions | 26.5*26*14cm |

| Usage | spot welding |

| Voltage | 110/220V |

| Power (kW) | 500W |

| Weight (KG) | 6.5 |

| Application | Jewelry Eyeglass Welding |

Please Feel Free to Contact us For More Details

Operation and usage methods

Before using the welding machine, check if the power supply meets the required voltage. Connect the screw of the corresponding polarity to the output wiring of the welding machine (tighten the nut when connecting the output wire to the output pole). When working, clamp the workpiece with the clamp on the output black line, close to the tungsten needle, and the distance depends on the size and shape of the workpiece. Generally, the distance between the tungsten needle and the workpiece is between 0.5-1 millimeter. After setting the welding position, press the foot switch to generate a high-temperature arc between the workpiece and the tungsten needle.

Instantly weld the workpiece together. The discharge end of the tungsten needle must be kept sharp before and during use to maintain a good discharge state.

Welding can achieve the desired effect by changing the output pulse current according to the size of the workpiece, the size of the welding point, and the process requirements (this machine can weld 0.5-2.0mm). When rotating the potentiometer clockwise (coarse adjustment, fine adjustment), the output pulse current increases, and vice versa, the output pulse current decreases.

Matters needing attention

1. Please confirm whether the plug of the machine matches your current voltage plug before use. If it does not match, please contact customer service for consultation before use

2. If the welding machine is placed in a damp place or not used for a long time, it may become damp. If the above phenomenon is found during use, it should be dried before use, and the machine should be well grounded. Please pay attention to safety when using.

3. When welding, strong light will be released, which may cause temporary darkness in the eyes. Therefore, please wear protective goggles during welding and do not look directly at the welding area.

4. When welding, do not press the tungsten needle tip against the workpiece and step on the foot switch, as this can cause a short circuit in the machine and affect its service life.

5. Please keep your hands dry when using this machine. If your hands are wet, you may feel numb during operation.

6. When welding, the foot switch should be pressed and released immediately. It cannot be pressed continuously as this will cause a short circuit in the foot switch and prevent it from working.

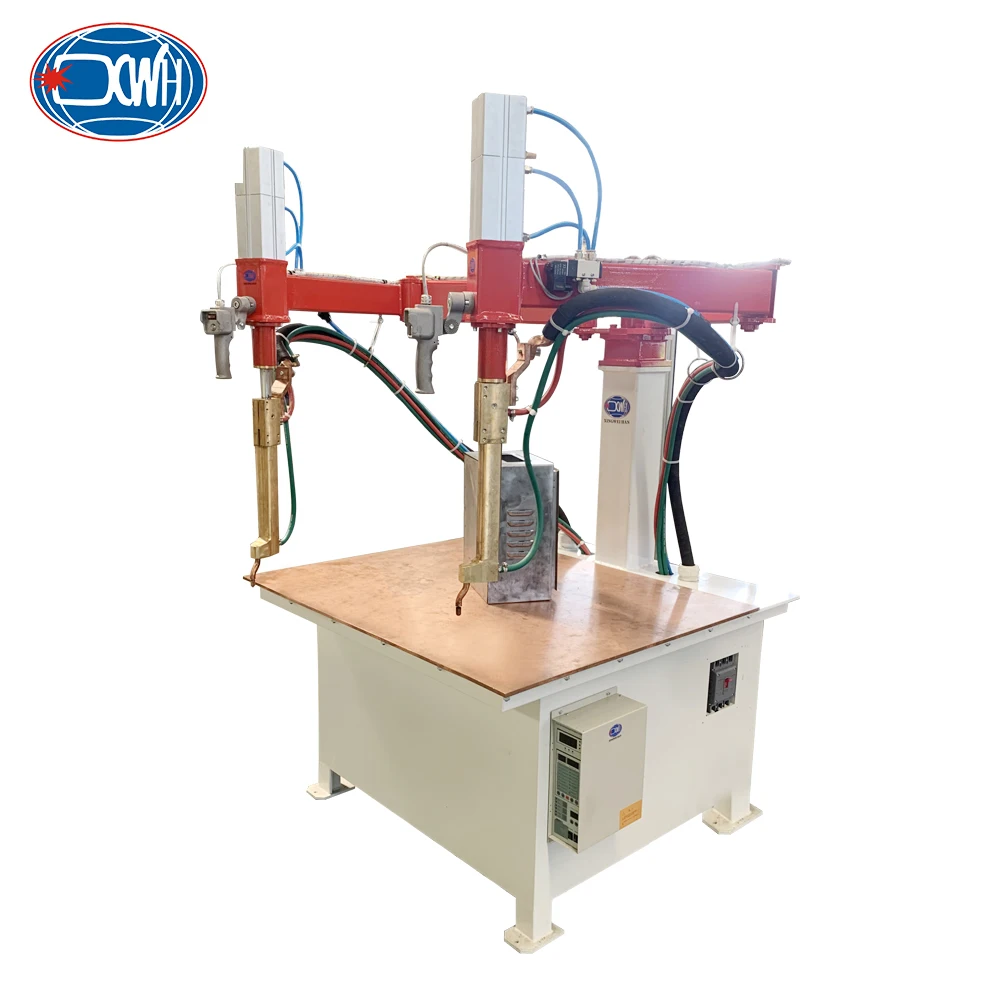

Похожие товары

Блеск 801D конденсатор для точечной сварки светодиодный цифровой дисплей SUNKKO 12KW аккумулятор портативный небольшой точечный сварочный аппарат

Автоматический Портативный Аппарат для точечной сварки MF 440 В 50 Гц

Точечная сварочная машина 2 мм для точечной сварки листового металла

Горячая Распродажа 35 кГц Настольный тип ультразвуковой точечный сварочный аппарат

RC3563 4-проводной 18650 Напряжение батареи тестер внутреннего сопротивления высокоточный на литиево-железо-фосфатный аккумулятор True

Sunkko 4 3 кВт 709 плюс точечная сварочная машина с дистанционной паяльной ручкой Электрический паяльник для сварки аккумуляторных батарей

Портативный многотехнологичный лазерный сварочный аппарат, сварочный аппарат для ремонта пресс-форм, инвертор, сварочный аппарат для ремонта

Новые поступления

Новинки товаров от производителей по оптовым ценам