Пластиковые гранулы из смолы высокопрочные термостойкие PBT 3020M

- Категория: PBT >>>

- Поставщик: Hangzhou Yuhang Trade Co. Ltd.

Сохранить в закладки 1600712295273:

Описание и отзывы

Характеристики

HANGZHOU YUHANG

Physical properties of | Test conditions | The test method | The test data | The data unit |

The proportion of | / | ISO 1183 | 1.13 | g/cm3 |

Melt flow rate | Melt flow rate | ASTM D1238 | 27 | g/10 min |

shrinkage | Flow: 1.60mm | ASTM D955 | 0.12-0.18 | % |

Bibulous rate | 23°C, 24 hr | ISO 62 | 0.060 | % |

Rockwell hardness | M meter scale | ASTM D785 | 87 | / |

Mechanical properties of | ||||

Tensile stress | yield | ISO 527-2 | 55.0 | MPa |

Tensile strain | The fracture | ISO 527-2 | >120 | % |

Bending modulus | / | ISO 178 | 2450 | MPa |

The bending strength | / | ISO 178 | 83.0 | MPa |

Thermal performance | ||||

Thermal deformation temperature | 0.45mpa, unannealed | ISO 75-2/B | 155 | °C |

1.8 MPa, without annealing | ASTM D648 | 60.0 | °C | |

The melting temperature | / | DSC | 223-227 | °C |

Linear expansion coefficient | The flow | ASTM D696 | 0.000090 | cm/cm/°C |

Electrical properties | ||||

Surface resistivity | / | IEC 60093 | 1.0E+13 | ohms |

Volume resistivity | / | IEC 60093 | 1.0E+15 | ohm.cm |

Dielectric strength | 2.00mm | ASTM D149 | 20 | V/mm |

Dielectric constant | / | ASTM D150 | ASTM D150 | / |

Dissipation factor | / | ASTM D150 | 0.0010 | / |

The electric arc resistance | / | ASTM D495 | 120 | sec |

UL flame retardant rating | 3.20mm | UL 94 | HB | / |

PBT application field

PBT resin is mostly processed into the use of mixing, after a variety of additives modified, and other resins blend can obtain good heat resistance, flame retardant, electrical insulation and other comprehensive properties and good processing performance. Widely used in electrical appliances, automobiles, aircraft manufacturing, communications, household appliances, transportation and other industries. For example, PBT modified by glass fiber can be used to manufacture electronic components requiring long-term stability at higher temperatures. PBT breakdown voltage is high, suitable for the production of high voltage resistance parts, because of its molten state of good liquidity, suitable for injection processing of complex structure of electrical parts, such as integrated circuit socket, printed circuit board, computer keyboard, electrical switch, fuse, temperature control switch, protector, etc.. Car bumper, carburetor, spark plug, fuel supply system parts, igniter, etc. In the field of communication PBT is widely used in program-controlled telephone integration module, terminal board, power tools and so on.

Introduction of PBT,

Polybutylene terephthalate (PBT) is a polyester made from the condensation of terephthalic acid and 1, 4-butanediol. It is an important thermoplastic polyester and one of the five engineering plastics.

Polybutylene terephthalate is a milky translucent to opaque, semi-crystalline thermoplastic polyester with high heat resistance. Resistant to strong acid, alkali, organic solvent, flammable, high temperature decomposition.

Polybutylene terephthalate is widely used in automobile, mechanical equipment, precision instrument parts, electronic appliances, textiles and other fields.

Polybutylene terephthalate is a milky translucent to opaque, semi-crystalline thermoplastic polyester with high heat resistance. Resistant to strong acid, alkali, organic solvent, flammable, high temperature decomposition.

Polybutylene terephthalate is widely used in automobile, mechanical equipment, precision instrument parts, electronic appliances, textiles and other fields.

PBT is non-toxic and has no stimulating effect on the skin. There are adverse environmental impacts in the production process, which need to be addressed.

PBT resin is packed with plastic lining or plastic woven bag, stored in dry, ventilated, rain, sun place storage, away from high temperature, open fire, avoid mixing and transportation with strong acid, strong alkali, strong oxidant.

Похожие товары

Инженерные пластиковые гранулы PBT пластиковый материал Gf30 %

Pbt гранулы PC/PBT поликарбонат + PBT долговечность и химическая стойкость

1 850,00 $ - 2 250,00 $

Инженерный Пластик PBT gf30 30% из стекловолокна гранулы для литья под давлением

Прямые продажи с завода PBT 3030-104 повышенная термическая стабильность при впрыске против

PBT Ultradur b4406g2 b4406g3 b4406g4 натуральный/черный полибутилентерефталат Лучшая цена Pbt Смола пластиковое

1,00 $ - 1,50 $

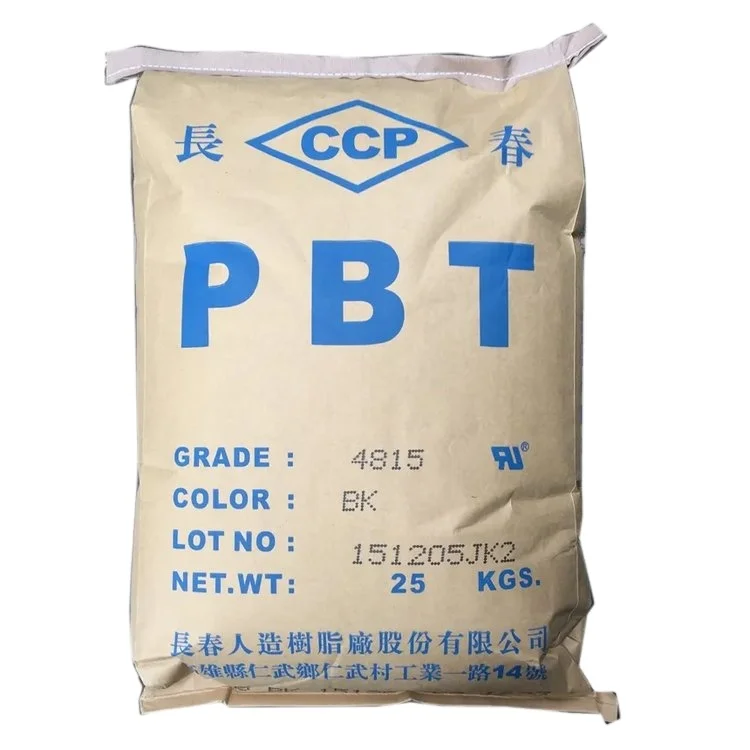

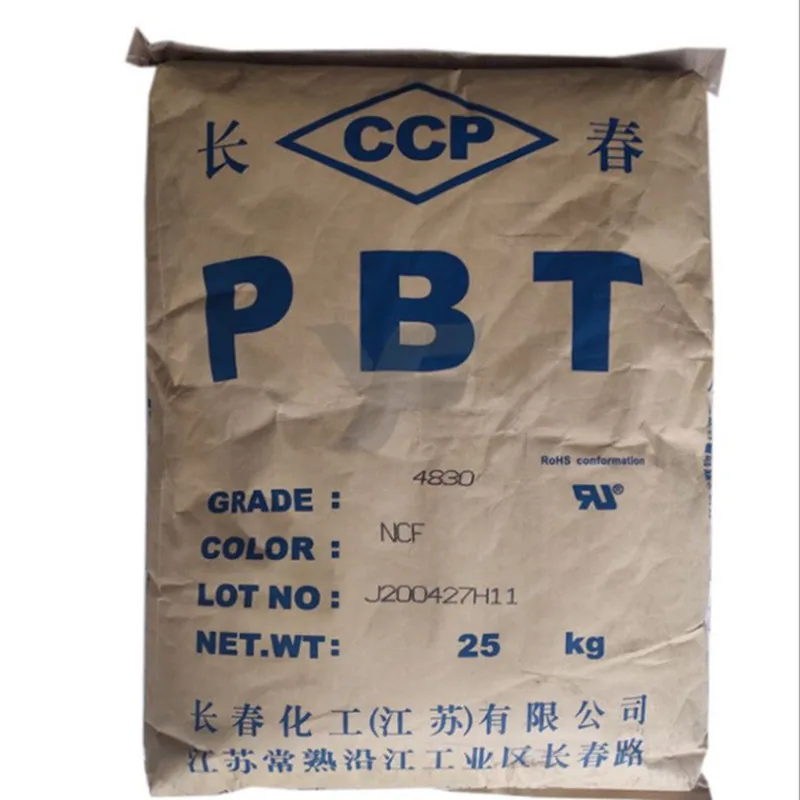

CHANGCHUN PBT 1100/4115 202FV 226U/4120/4130/4140/4815/4830/4830BK/BK NCF NCB BKF/4820NCB/3040/4830NCF/3015

1,50 $ - 2,50 $

Полибутилентерефталатное пластиковое сырье из смолы Pbt 100% гранулы натурального пластика Pbt/Смола для литья под

Новые поступления

Новинки товаров от производителей по оптовым ценам

Умный цифровой электронный ручной инфракрасный лазерный термометр для ветеринарного и медицинского мониторинга человека

5-10 $

Цифровой инфракрасный лазерный термометр для взрослых

5,90-6,70 $

Командная версия 24-скоростной ультралегкий карбоновый шоссейный велосипед Гоночная рама и комплект колес

Четырехцилиндровый двигатель CA6110/125G5 части клапана 1007011-A013-0000 1007016-A013-0000

0,50 $

55203781 46740344 55181201 55266538 зубчатый шкив коленчатого вала для FIAT 500 BRAVA BRAVO DOBLO PANDA PUNT0

3-3,70 $

Оптовая продажа 100% Рафинированное Масло из семян подсолнечника малазия масло для приготовления пищи

GY031 металлическая рамка пользовательских игровых сидений Sim гоночные игровые сиденья симулятор вождения кабины для Xbox 360 Logitech G25 G27 G29 G920

88-143 $

Роскошные пользовательские островные стулья современные кухонные с выдвижными ящиками и раковиной кухонный шкаф U-образной формы из нержавеющей стали

160-180 $