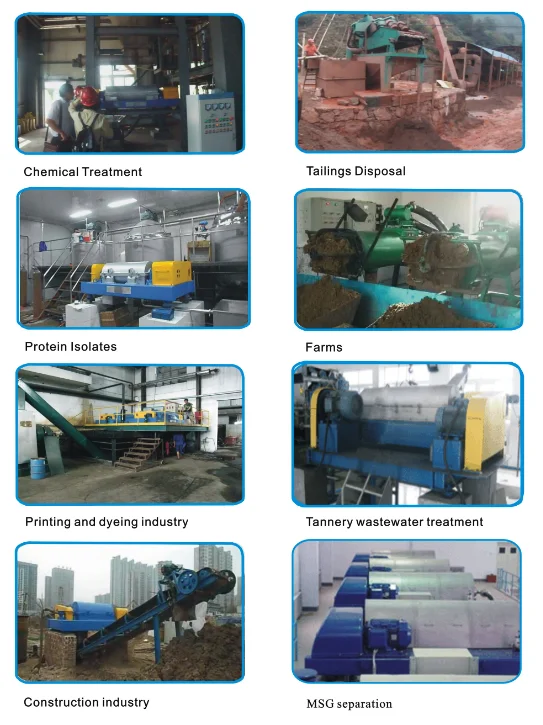

LIAOYANG WINTECH INDUSTRIAL CO., LTD is a Centrifugal Filter Equipment processing and manufacturing as the main industry, the main products are Horizontal Decanter Centrifuge, Disc Centrifuge, Tubular Centrifuge, Flat Series Centrifuge, CO2 Supercritical Extraction Equipment, and corresponding supporting equipments, eg. food line, pharmaceutical line, chemical line. At the same time to undertake standards and non-standard products. Our equipment is exported to Europe, America, Southeast Asia, Africa and other countries, and has been praised by foreign customers.

Our company has professional engineers with strong new product development ability, and can develop equipment products according to the actual needs of customers. Our company has ISO 9001 certification, CE certification and other relevant authoritative parts of professional identification and recognition. At the same time, facing the fierce market competition, our company is relying on its own advantages, integrating external resources, optimizing internal management, constantly exploring and innovating, and striding forward in the direction of business specialization and diversification. Our company adheres to the business philosophy of quality and service, and wholeheartedly provides high-quality products and services for new and old customers to meet the needs of customers to the maximum extent. Serve customers, achieve customers, sincerely look forward to cooperating with new and old customers to create a better future.