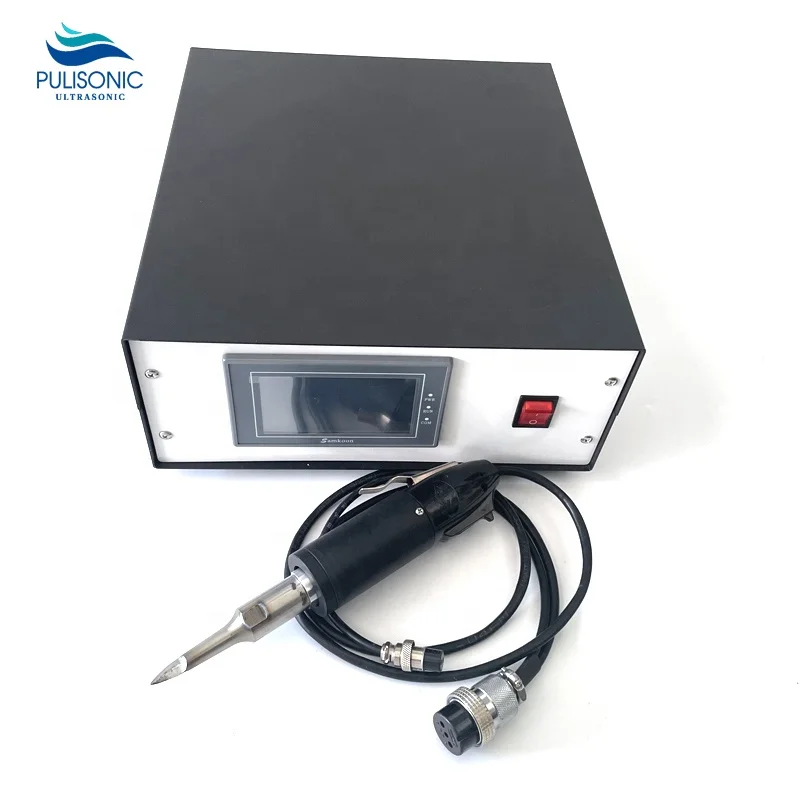

1000 Вт 40 кГц ультразвуковой кавитационный нож для резки пластиковой машины с генератором ЖК дисплея

- Категория: >>>

- Поставщик: Foshan Pulisonic Ultrasonic Technology Co. Ltd.

Сохранить в закладки 1600716894504:

Описание и отзывы

Характеристики

The basic structure of the ultrasonic cutting machine. Ultrasonic transducer, ultrasonic horn, ultrasonic cutting knife, ultrasonic generator.

Ultrasonic generator: the mains electricity is converted into high frequency and high voltage alternating current, which is output to the ultrasonic transducer. Ultrasonic transducer is equivalent to energy conversion device, it can convert the input electric energy into mechanical energy, namely ultrasonic wave. The ultrasonic transducer stretches back and forth in the longitudinal direction, and the frequency of the stretch movement is equal to the frequency of the high-frequency alternating current supplied by the driving power source.

Ultrasonic horn: The ultrasonic horn amplifies the output amplitude of the ultrasonic transducer.

Ultrasonic cutter: further amplify the amplitude and focus the ultrasound. Ultrasonic waves are output, and the cutting knife is used to concentrate the ultrasonic energy into the cutting part of the material to be cut. Under the action of huge ultrasonic energy, this part instantly softens and melts, and its strength is greatly reduced. Only a small amount of force is required to achieve the purpose of cutting materials.

Features:

High stability: When the ultrasonic generator is working, it generates 40KHz electromagnetic vibration, which is transformed into mechanical vibration and transmitted to the cutting knife and the material to be cut. The slitting is performed mechanically, so there is no need for sharp cutting edges, and the blade wear is small, and at the same time The cutter head can be replaced by yourself.

No pollution: When the ultrasonic knife is cutting, the temperature of the knife head is lower than 50 ℃, so smoke and odor will not be generated, which eliminates the danger of injury and fire during cutting.

Neat cutting: Since the ultrasonic is cut by high-frequency vibration, the material will not stick to the surface of the blade, and only a small amount of pressure is required when cutting. It will not deform or wear for fragile and soft materials. The fabric will be automatically sealed at the same time. Will cause edge collapse.

The operation is simple: the cutting knife is connected to the ultrasonic generator, the generator is connected to the 220V mains, and the switch can be turned on to cut. It supports hand-held cutting and is equipped with an air-cooled interface.

Wide range of applications: various textile materials and plastic sheets can be ultrasonically cut, such as natural fibers, synthetic fibers, non-woven fabrics and knitted fabrics can be ultrasonically cut.

Model | Power | Frequency |

PLS-HJDY-300W | 300W | 28KHZ,30KHZ,35KHZ,40KHZ |

PLS-HJDY-500W | 500W | 28KHZ,30KHZ,35KHZ,40KHZ |

PLS-HJDY-800W | 800W | 28KHZ,30KHZ,35KHZ,40KHZ |

PLS-HJDY-1000W | 1000W | 15KHZ,20KHZ,28KHZ |

PLS-HJDY-1200W | 1200W | 15KHZ,20KHZ,28KHZ |

PLS-HJDY-1500W | 1500W | 15KHZ,20KHZ |

PLS-HJDY-2000W | 2000W | 15KHZ,20KHZ |

PLS-HJDY-2600W | 2600W | 15KHZ,20KHZ |

PLS-HJDY-3200W | 3200W | 15KHZ |

PLS-HJDY-4200W | 4200W | 15KHZ |

Похожие товары

6 оси сварочный робот диапазон 1500 мм MIG TIG

Тестер напряжения аккумуляторов Allsun BT21, электронное устройство 9 В AAA AA, со светодиодным дисплеем

Сделано в Китае 48V-84V 600A скорость приводного двигателя контроллер который заменить curtis 1244-6661

Пищевой порошок Дикалия гидрофосфат dkp cas 7758-11-4, Дикалия фосфат, цена россыпью

Новинка 2022, GPS-локатор для автомобилей и мотоциклов, точное позиционирование в режиме реального времени, GSM GPRS 356, GPS-локатор для автомобиля, GPS-Трекер против потери

32 amp промышленная пробка BJ-60YT/YZ-4 мужского и женского пола 4Pin штекер 60A для бурового оборудования 4 этапа разъем

Керамический порошок с дальним инфракрасным излучением для шелкографии на текстильном покрытии

Новые поступления

Новинки товаров от производителей по оптовым ценам