Алюминиевая бесшовная трубка производство алюминиевых труб 6061

- Категория: Other Aluminum >>>

- Поставщик: Shanghai Nansen Industry Co. Ltd.

Сохранить в закладки 1600717581775:

Описание и отзывы

Характеристики

aluminum seamless tube aluminum pipe manufacture 6061 aluminum tube

The seamless aluminum tube is made of pure aluminum or aluminum alloy by extrusion processing along its longitudinal length of the hollow aluminum tube without weld. The seamless tube will ideally be a solid metal tube with each end connected to another tube without having any welding joint.

| Product Name | Aluminum seamless tube |

| Material | Aluminun Alloy |

| Al (Min) | 99.7% |

| Grade | Alloy 7001,7005,7075 Alloy 6061,6063,6082 |

| Shape | Round, Oval, Square, Rectangle,Flat,Special Shape etc. |

| Largest Outer Diameter | 200mm |

| Min. Wall Thickness | 0.7mm |

| Max. Length | 12m |

| Color | Black,Silver,Blue,Gold, Red,Green etc. |

| Application | pressure vessels, hydraulic cylinders, compressed gas cylinders, drive shafts, lighting applications and bus conductors |

| Surface Treatment | Mill finish,sand blasting,polishing,anodizing,wood grain,electrophoresis painting,power coating |

| Technique | Cold drawn |

| Certificates | ISO, CE, SGS |

| Standards | GJB 9001B-2009 GB/T I9001-2008/ISO 9001:2008 |

Mechanical Properties

Alloy | Tensile Strength | Yield Strength | Hardness | Elongation% | Temper |

7001 | 600-680 | 600-620 | >140 | 5-8 | T3 - T8 |

7005 | 600-680 | 600-620 | >140 | 5-8 | T3 - T8 |

7075 | 600-680 | 600-620 | >140 | 5-8 | T3 - T8 |

6061 | 290-310 | 250-270 | HB90-110 | 12-17 | T3 - T8 |

6063 | 290-310 | 250-270 | HB90-110 | 12-17 | T3 - T8 |

6082 | 290-310 | 250-270 | HB90-110 | 12-17 | T3 - T8 |

Advantages of seamless tube and pipe

· No weld seams, preferred for pressure vessels

· More uniform anodizing appearance, especially on heavier wall sections

· No weld seams that could split in forming operation

· Increased structural integrity

· ultra-fine-grained material

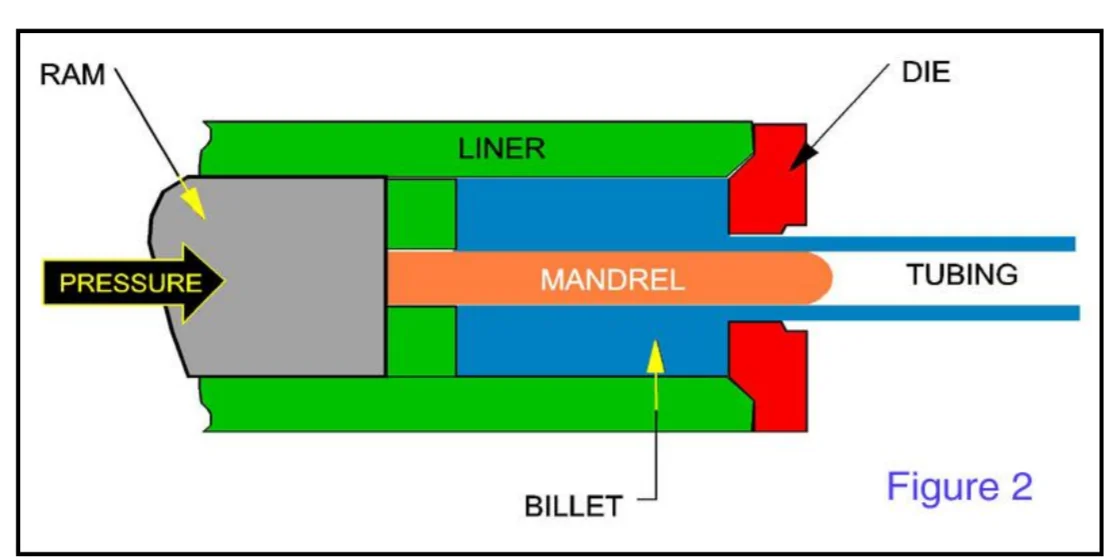

Extrusion by mandre (s. standard EN 755-1, -2, -7) The essential features are > seamless tube wall (no pressure welds, homogeneous microstructure) > larger concentric tolerances compared to porthole die extrusion > shapes limited to concentric cross-sections.

Ultrasonic testing of aluminium alloy specimens

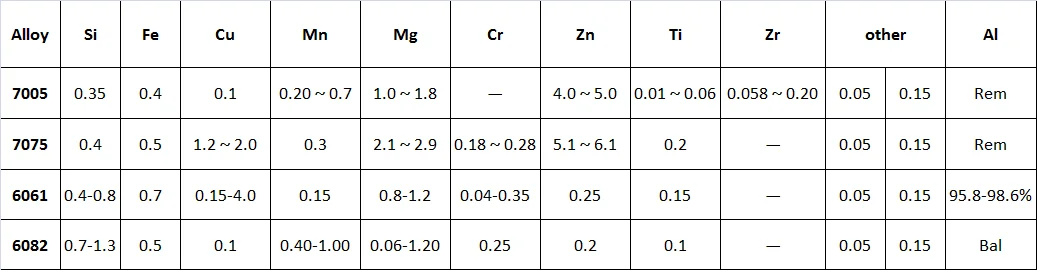

Alloy Analysis

1>7075 Aluminum vs. 6061 Aluminum

Because they both contain largely the same alloys, 7075 and 6061 aluminum are often cross-compared as grade options for any given application. But the two aluminum grades’ differing composition ratios make them respectively suitable for different types of production needs.

7075 aluminum contains more zinc than 6061. This makes it more corrosion resistant and strong, but less easily shaped than 6061, which is more malleable, weldable, and versatile. As a result, 7075 is preferable for high stress applications like aerospace or military equipment, while 6061 is useful for crafting particularly shaped parts that face less strenuous wear, like transit infrastructure, stairs, or small water vessels. Analyze the pressures of your project's use environment to make the right aluminum grade choice.

2>6063 Aluminum vs. 6061 Aluminum

Likewise, 6061 aluminum often draws comparisons with 6063 aluminum, as both grades are commonly used to craft structural parts. While the two are extremely similar and often present negligible differences in application, 6061 provides a notably higher yield strength for parts that need to withstand exceptional force. Regardless of your choice, 6061 or 6063 aluminum will provide your project with high weldability and formability.

3>Properties

6061 is typically bought to meet chemistry requirements rather than physical requirements. For that reason, physical properties are generally not provided unless requested prior to production. Any material can be sent to a third party after production to be tested for physical properties.

4>Typical Uses

· Railway car components

· Bridge components

· Pipe fittings

· Wheels and various transportation end uses

Seamless pipe and tube is typically used for pressure vessels, hydraulic cylinders, compressed gas cylinders, drive shafts, lighting applications and bus conductors. They are recommended for applications requiring:

· Critical pressure ratings

· Demanding forming applications

· Critical strength requirement

· Uniform anodizing appearance

Ms. Keila

Shanghai Nansen Industry Co., Ltd.

Address: Pudong District, Shanghai, China.

Tel: 86-21-2024 9001

Wechat /what'app : 0086-138 1720 9443

Email: sales at nansencn. com

Website: www.nansencn.com

Похожие товары

Прямая поставка с завода низкая цена экструзионный профиль экструдированный литой дизайн алюминиевый

Алюминиевая экструзия 6063 Лом/алюминиевый лом 99%/колесный из

Лидер продаж a7 a8 adc12 алюминиевые слиток от 91% до 98% 99 7 чистые слитки из чистого алюминиевого

Алюминиевая полоса из алюминиевого сплава 1060 H24 3003H14 5052H32 O country чистая

Алюминиевые слитки 99.9%, алюминиевые слитки 99.7%

Изготовленный на заказ алюминиевый сплав с высокой затылочной литой алюминия для исследований и

Оптовая продажа от производителя алюминиевая проволока без сплава 10 мм диаметр 1070 дюйма 20 для

Новые поступления

Новинки товаров от производителей по оптовым ценам