Заводская горячая Распродажа керамическая шаровая мельница для шлифования лепидолита spoduмола

- Категория: >>>

- Поставщик: Henan Zhengzhou Mining Machinery Co. Ltd.Henan Ltd.

Сохранить в закладки 1600729613336:

Описание и отзывы

Характеристики

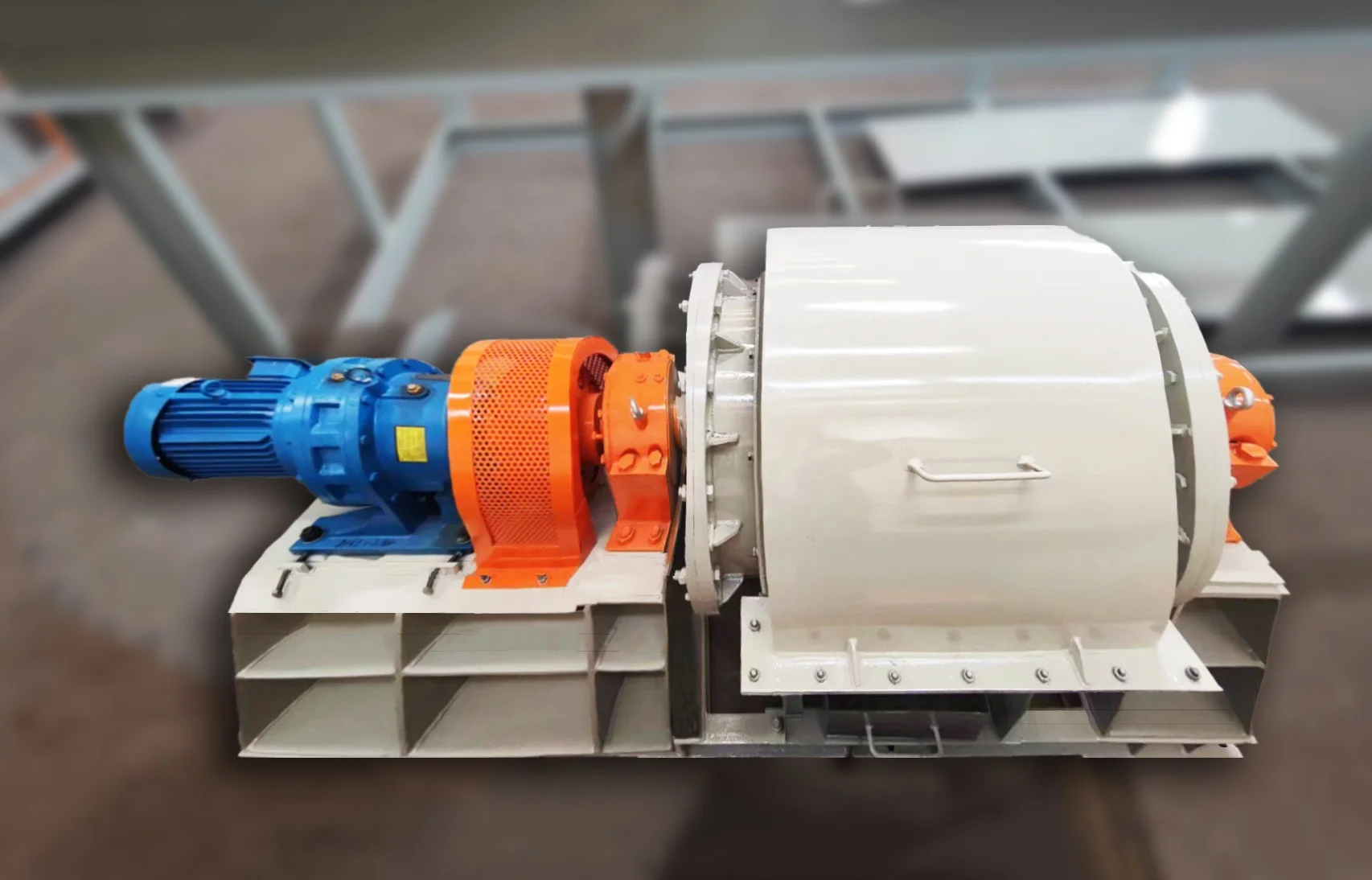

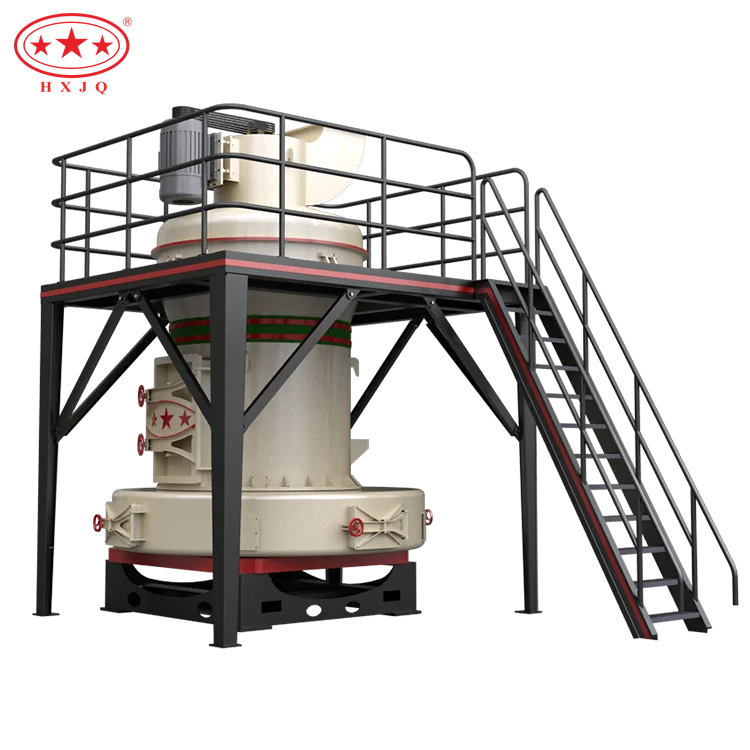

Ceramic ball mill is also called Intermittent ball mill/Batch ball mill. Ceramic ball mill is mainly used for mixing and grinding of ceramic raw materials, Aluminium powder,Lepidolite, Spodumene, kaolin and glaze materials etc. It is widely applied in industrial production of high fine grinding materials. The fineness of products is uniform and power is saved. Ceramic ball mill grinding has dry and wet ways, of which the dry grinding can produce ultra-fine powder with the fineness of 1000 mesh. The machine can adopt different types of lining plates according to production needs to meet different needs.

The material goes to the first hopper after the spiraling by the quill shaft from the feeding equipment. The hopper has ladder sheathing or corrugated sheathing with steel balls inside, which will fall under the effect of centrifugal force by barrel turning to ram hard and grind material.

Features

1. The type of lining board can be changed: according to different materials, different lining boards can be used to meet different needs;

2. Low price: Compared with other ball mills, ceramic mills have low prices and quick cost recovery;

3. Small land area required: Compared with other mills, the length of the ceramic mill is short, so it occupies a small area;

4. Stable operation: The transmission of the main engine adopts a closed gear, so the stability of the transmission is enhanced.

Technical Parameter

| Model | Loading Capacity (tons/time) | Rotating Speed (r/min) | Reference Power (kW) |

| 600*700 | 0.05 | 50 | 2.2 |

| 800*600 | 0.075 | 42 | 3 |

| 900*1200 | 0.2 | 38.5 | 5.5 |

| 1300*1500 | 0.5 | 33 | 7.5 |

| 1500*1800 | 1.2 | 28.5 | 11 |

| 1800*2000 | 1.5 | 24 | 15 |

| 2600*2800 | 5 | 16.5 | 37 |

| 3000*3800 | 10 | 14.5 | 57.2 |

| 3200*4600 | 15 | 13.5 | 75 |

| Ceramic, silica, rubber, metal (supporting power will vary depending on the material of the liner and the grinding material) | |||

1. Excellent installation team or installation service for you;

2. Provide you with operating and training services;

3. Help with the equipment commissioning and solve problems in trial operation;

4. Check before acceptance of single equipment or whole production line;

5. Service items including follow-up visit, customer satisfaction surveys and so on;

6. Timely provide you with necessary accessories after acceptance;

7. Provide you with warranty services of repair, replacement and refund if conditions are fulfilled;

8. Help you solve other problems.

Henan Zhengzhou Mining Machinery Co., Ltd. was founded in 1956, area of 70000 square meters, plant construction area of 40000 square meters with six modern workshops, two heavy machinery workshops, one Municipal Technology Center and more than 260 sets of machining, assembling, welding and other equipments. Its fixed asset value has exceeded 100 million RMB. Henan Zhengzhou Mining Machinery Co., Ltd has become an integrated modern enterprise with scientific research, design, development, manufacturing, sales, installation, commissioning and training services.

The main products of company include: ball mill, rotary kiln, preheater, cooler, crusher, bucket elevator, dust collector,conveyor and other equipments relate to metallurgy, cement, lime, refractory, chemical industry. The products of Henan Zhengzhou Mining Machinery Co., Ltd have been sold to every province of China and exported to Russia, Korea, Vietnam, Malaysia, Nepal, Bangladesh, Mexico, Armenia, Africa, South America and other countries and regions.

Over 60 Years Mining Equipment Manufacturing Experience

Customers from over 130 countries chose us

A Team of Professional Engineers & Considerate After-sales Service

In order to recommend suitable design for you, please kindly tell me:

♥ How many tons do you want to produce per hour? like 5tph

♥ What is your raw material to process?

♥ What are output sizes you want? like 150-300 meshes

Can you tell me your email and WhatsApp? So that our manager can quote for you after selecting the appropriate model. Thank you.

Now, please click the following contact to send us email !

↓↓↓

Похожие товары

Новая Золотая шаровая мельница для цемента навоза угля керамики

Золотая руда серебряная медная свинцовая цинковая молибденовая рудная мельница/мелкая шаровая мельница для продажи

Мельница для мелкого баритового гипса

Шлифовальная машина Raymond оборудование для шлифовки минеральных материалов линия по производству гипсового порошка

HGM160 Raymond мельница цена порошковая шлифовальная дробилка завод

Лабораторная шаровая мельница серии XMQ небольшая минеральная дробильная машина для продажи

Масляный проппант керамический песочный стержень шаровая мельница

Новые поступления

Новинки товаров от производителей по оптовым ценам