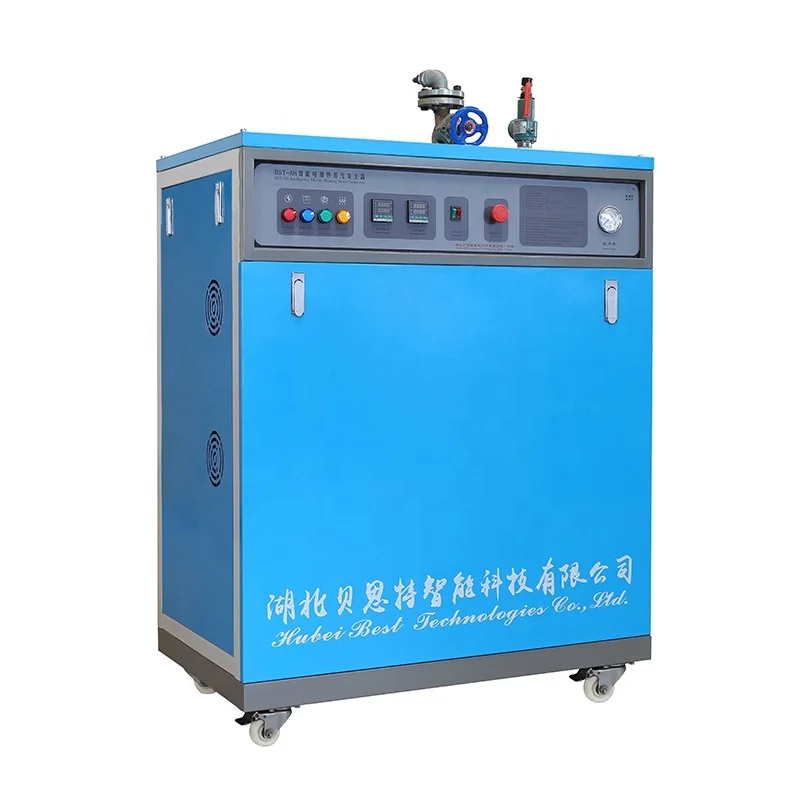

Небольшой подвижный электрический парогенератор 9 кг для гладильного

- Категория: Boilers & Parts >>>

- Поставщик: Zhangjiagang Delon Thermal Machinery Co. Ltd.

Сохранить в закладки 1600740568822:

Описание и отзывы

Характеристики

Small Movable 9Kg Electric Steam Generator for Ironing Table

"DELON THERMAL" offers a complete line of small electric steam generators for heating and process applications that range from 6kW to 36kW (9kg/h to 50kg/h).

"NEOSOUL" brand Electric Steam Boilers are extremely efficient because the heating elements are totally immersed in water and the pressure vessel is fully insulated, which results in minimal radiation losses. With the carefully calculated heat to steam ratio, operating pressures are achieved quickly with maximum efficiency.

1) Electric steam boilers are efficient, quiet and safe for your processing needs.

2) Vertical design requires minimal floor space.

3) The heating elements are easily accessible-permit quick removal for service or inspection.

4) No NOx(Nitrogen oxides) emission. Electric boilers have no wasted fuel going out the stack as electric boilers are environmentally friendly.

5) Completely wired control panel box located in front of the boiler.

6) All electrical components have demonstrated signs CE and equipped with world famous brands (SIEMENS, WEIDMULLER, OMRON, LS...) to ensure product safety and service life

7) 98% thermal efficient because the flange heaters are totally immersed in water.

8) One-key blow-down function.

9) Power switch function to allow different steam using requirements.

10) Steam pressure adjustable to allow different steam using requirements.

Model / Series | Unit | NS-6DS | NS-9DS | NS-12DS | NS-18DS | NS-24DS | NS-36DS |

Rated evaporation | Kg/h | 9 | 13 | 17 | 25 | 35 | 50 |

Input power | kW | 6 | 9 | 12 | 18 | 24 | 36 |

Rated current | A | 9.2 | 13.8 | 18.4 | 27.6 | 36.7 | 55.1 |

Main power supply | V/HZ | 380V±5%/50HZ, 3Ph (3P+N+E) or Custom made | |||||

Rated working pressure | MPa | 0.7 (Custom made) | |||||

Saturated steam temperature | °C | 170 (Custom made) | |||||

Steam outlet diameter | mm | DN15 | DN15 | DN15 | DN15 | DN15 | DN15 |

Safety valve outlet diameter | mm | DN15 | DN15 | DN15 | DN15 | DN15 | DN15 |

Water inlet diameter | mm | DN15 | DN15 | DN15 | DN15 | DN15 | DN15 |

Blow-down outlet valve diameter | mm | DN15 | DN15 | DN15 | DN15 | DN15 | DN15 |

Overall size | C mm | 660 | 660 | 700 | 700 | 750 | 750 |

B mm | 395 | 395 | 410 | 410 | 460 | 460 | |

A mm | 740 | 740 | 790 | 790 | 920 | 920 | |

Net weight | Kg | 62 | 62 | 78 | 78 | 95 | 95 |

Note: We're able to design and manufacture the customized products.

DELON has been marketing the electric steam generators for 10 years, and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

1) Can your steam generators meet the heating needs of my production?

If this is your first purchase, all the specifications and the operation requirements should be provided, our engineers will calculate and advise the suitable models for your reference.

2) What are the payment terms?

For new customers, usually we accept the 35% T/T as the prepayment, the balance shall be paid before shipment, and if you have been with us for years or due to the restrictions of foreign exchange policy, we do offer L/C at sight.

3) Do you provide customized service?

We can design the steam generators according to your requirements (temperature, material, power, control mode, control accuracy, etc.) We will also provide you with expert guidance at the same time, based on our years of experience in this temperature control field.

4) How long does it usually take to manufacture?

Depends on whether you want to do customization of your electric oil heaters or not, and also depends on the quantity you want to order.

For regular machines in LCL, the lead time is 5-10 working days.

For customized products and bulk orders in FCL, the lead time is 15-30 working days.

5) What's the warranty for the machine?

Generally, the warranty 24 months counting from the date against shipment, during the warranty period, if there's any parts damaged in quality, you can get the new ones for free.

6) Do you test the machine after the production?

Before shipment, our engineer will arrange the functional tests for each machine.

7) Can I come to China for factory inspection?

Of course, but it is better to wait until the epidemic subsides. Now we support using ZOOM for online factory inspection.

8) How often should the heating elements be changed?

Depends on frequency of use, generally speaking, you need to change this part every 3 to 4 years.

Похожие товары

320000 BTU пропановая струйная горелка с 32 латунными насадками, наружные горелки

Автоматический Газовый Котел горячей воды паровой котел высокого давления

Электрический паровой котел с паровым утюгом/паровой рисовой

Горизонтальная Паровая горелка на

Паровой котел beist AH 18 кВт 60 паровой для молока стирки пальмовых

6t Автоматический Газовый паровой котел с

Новый стиль эффективный горизонтальный обогреватель для нефтяных

Новые поступления

Новинки товаров от производителей по оптовым ценам