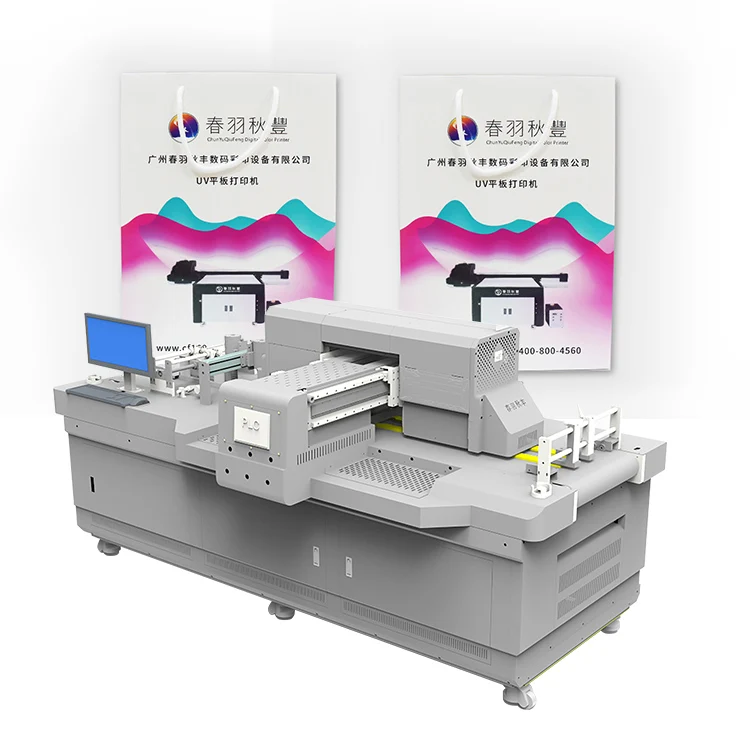

Новейшая модель 2023 высокоточная автоматическая машина для цифровой печати с высокой четкостью и жесткой картонной коробкой из гофрированного картона

- Категория: >>>

- Поставщик: Qingdao Perfect Equipment & Parts Co. Ltd.Qingdao Ltd.

Сохранить в закладки 1600744685031:

Описание и отзывы

Характеристики

CE 2023 latest model High-definition high-precision automatic corrugated cardboard rigid carton box digital printing machine

Model | PFK 2508 | PFK 2516 | |

Ink sprayer | Micro piezoelectric high-precision nozzle | ||

Sprayer quantity | 8 pcs | 16 pcs | |

Ink type | Water-based dye ink for cardboard | ||

Colors | C/M/Y/K | ||

Spraying height | 2-4mm | ||

Printing precision | More than 360*600 dpi | ||

Printing speed | 600 square meters/hour | 1200 square meters/hour | |

Printing max area | 2500*1350mm | ||

Drying speed | Immediately after printing | ||

Working temperature | Workshop temperature 20-25 degree, 50%-70% humidity | ||

Ink supply | Automatic continuous ink supply | ||

Cardboard feeding | Front lead edge automatic feeding | ||

Max feeding pile height | 43 cm | ||

Cardboard thickness | 3-30mm | ||

Software | Professional RIP software | ||

Operation System | WIN7/WIN10 | ||

Working power | 380V 50-60Hz 3Phases, about 20KW | ||

Machine sizes(L*W*H) | 5645*3750*2123mm | 5645*4150*2123mm | |

Machine Weight (KG) | About 4500KGS | About 5000KGS | |

Carton box Printing effect

PFK 2508P CNC automatic corrugated cardboard box making machine

Suitable for : Single or double wall corrugated cardboard

Cardboard thickness: 2-10mm

Max weight of the cardboard:1200GSM

Max feeding cardboard sizes: 2500mm width* infinite length

Min feeding cardboard sizes: 200*650mm (W*L)

Order changing time : 20-50 seconds

Processing boxes sizes : More than 50 types

Production capacity: 400-600 pieces/hour( depends on boxes shapes and sizes)

Standard slotting blade : 2 pieces 500mm length

Standard vertical cutting blade: 4 pieces

Standard creasing line blade: 4 pieces

Crossing cutting blade: 1 piece

Air source pressure and air consumption: 0.6-0.7Mpas 75L/Minute

Weight: About 3500 kgs

Working power : 380V 50Hz 3Phase 3.5KW( 220V or 440V need to be customized)

Machine sizes: 3900(W) * 1900(L)* 2030mm(H)

Hand hole making Yes

Cardboard feeding: Front leading edge or fanfolded auto feeding

2800mm width auto corrugated cardboard carton box making rotary die cutting machine price

This machine is a special equipment for processing special-shaped box, widely used in the three layers, five layers corrugated cardboard box shaped piece of paper, pressing, cutting, punching and other processes (handle) once completed. The machine adopts the round pressing circle process mode, which can be used for stepless speed regulation, electronic counting and electric phase adjustment. The utility model has the advantages of high efficiency, energy saving, safety and practicality. It is the ideal equipment for the special box packaging, such as the processing or the inner packaging, etc. in the modern carton packaging.

The machine has three parts, cardboard auto feeding unit(or semi-auto chain driving), die cutting unit and electric control unit

Die cutting part is a major part of the machine, the main wall and the upper and lower die roll, motor, electrical components. Cutting roller is installed under the box sheet template roller, according to box sheet prepared template, fixed by screws on the roller. A rubber pad on the die roll surface, when the Board sent to the site in the upper and lower roller, die-cutting roll and blade under the action of the cardboard box sheet and cut off residual material separation

Characters of our corrugated cardboard box making die cutting machine

1) Pre-pressing wheel, the pre-pressed cardboard is not easy to be crushed.

2) The outer diameter of the die roll is 430mm (excluding the blade), and it is made of high-quality cast steel. Surface research grinding, hard chrome plating, balance correction, increase running stability. Adapt to the die height of 25.4mm. Thickness of wood stencil:16mm (for three-layer cardboard) 13mm (for five-layer cardboard).

3) The outer diameter of the rubber pad roller (without rubber pad) is 388.9mm, and the surface of the cast steel material is ground and plated with hard chrome.

4) Die-cutting superior force rubber roller mechanically travels 30mm laterally, adopts differential speed compensation device, no matter how the diameter of the rubber pad changes, the linear speed of the rubber pad is automatically tracked and compensated without manual adjustment; more wear-resistant rubber pad thickness 8mm, width 250mm. The gap between the rubber pad roller and the die roller is pneumatically controlled, the paper feeding is stopped, the soft roller automatically rises, and returns to the working position when working;

5) The equipment is equipped with a rubber pad repairing device, and the worn rubber pad roller can be repaired by itself electrically, so as to keep the superior glue on the surface of the rubber pad with a longer service life. Die cutting roller for centrifugal casting material, wall thickness 45mm, balance correction, hard chrome plating.

6) The wall plate is made of high quality ductile iron, and the wall thickness is 40mm.

Model | AGM2800 |

Max die cutting size | 1400*2400 mm |

Min die cutting size | 350*600 mm |

Cardboard thickness | 2--8 mm |

Design working speed | 120 sheets/min |

Working speed | 100-120 sheets/minute |

Working power | 380V/50Hz/3Phase 3.0KW |

Precision | ±0.5 mm |

Sizes(L*W*H) | About 4200*2000*1800MM |

Die cutting roller length: 1600-3000mm ( customizes)

Electric phase adjustment, Photoleclectric counting

The die cutting roller is penumatic lifting, can protect the die cutting rubber cushion perferctly.

Popular among Europe market, meet with CE standard.

Jaw type manual heavy cardboard leather plastic platen die cutting creasing machine

Indentation machine (Creasing Die Cutting Machine) is also called jaw butterfly die cutting machine, cutting machine, rolling car, and box machine. It uses steel knives (knife molds), metal molds, steel wires (or templates carved from steel plates) to pass The embossing plate applies a certain pressure to roll the printed product or cardboard into a certain shape. The shape is mainly used for cardboard, corrugated cardboard, plastic sheet, leather, cork, self-adhesive, EVA, double-sided tape, electronics, etc. It is an important equipment for post-press packaging processing and forming.

Packaging of our corrugated cardboard box digital printer machine

plastic film and soft material wrapped, then load into 20" container

Delivery of our corrugated carboard carton box making manufacturing machines

What service you can enjoyed from us for corrugated cardboard carton box making printer machine

1) Provide you good quality corrugated cardboard die cutting machines, corrugated box folding gluing machines, carton box printing machines, cardboard slotting machines, carton box stitching forming machines with the most economic prices.

2) Design and produce the most economic 2 ply, 3 ply, 5 ply, 7 ply corrugated cardboard production line for you according to your budget, plant covering area.

3) Super after sales service and technical support, related parts supplying for your maintenence, engineers overseas support and service

4) Our 24 hours online service for automatic cardboard carton box making printer machine

www.pefct.com

www.autoboxmachine.com

www.eggboxtraymachine.com

What's app: +86 18561832088

www.paperpulpmoldingmachine.com

1) Established in1982 year, and start to produce corrugated cardboard making

machines, cartons flexo printing machines, tissue paper making machines since 1991.

2) Covering area is more than 16000 square meters, total assets is more than ten

million US$

3) Workers more than 300, and engineers 35, manage persons 15.

4) Advanced production equipment: tungsten carbide corrugated rollers

manufacturer and repair center, computer corrugated roller grinding machine, back to

large round grinder and complete advanced production processing equipment; CNC

processing equipment.

5) Special for: corrugated cardboard making single facer machine, carton box die cutting machine, corrugated box printing machine, cnc cardboard box making machine, carton box digital printer, 3 layer, 5 layer, 7 layer corrugated cardboard production lines, waste paper recycling egg tray production lines.

6) New developed items recent 10 years: paper pulp making machines, hydrapulper,

paper making pressure screen, egg tray making machines, tissue paper converting and

processing machines

7) Our corrugated cardboard production lines are famous brand in north of China,

and our egg tray making machine, cardboard box making printing machine, automatic carton box making machine, cardboard sheet printer machine, tissue paper

making machines, toilet paper converting machines already been exported to more

than 75 countries, like Ukraine, Argentina, South Africa, India, Egypt, Philippine, Russia, Spain etc

For more details about our corrugated cardboard carton box making printer machine, corrugated cardboard box making die cutting machine, cnc automatic carton box making machine, please email us freely !

Похожие товары

Многоцветный гофрированный картон принтер струйная печатная машина для производства картонных коробок Прямая Фабрика картонная

Все размеры A1 A3 3050 4050 4060 6090 2513 UV планшетный принтер High Drop для бутылок чехол телефона и т. д. печать

Цифровая бумажная коробка однопроходная печатная машина гофрированный картон Печатный однокартонный принтер

Foofon оптовая продажа цифровой принтер высокого качества для однопроходного принтера в картонной коробке

Печатная машина для металла бумаги дерева пластика большой гофрированный картон сублимационный Ультрафиолетовый планшетный принтер чехла телефона

Цветной струйный принтер

Высококачественный цифровой струйный принтер Kelier для картона Гофрированная коробка Однопроходный картонный

Новые поступления

Новинки товаров от производителей по оптовым ценам