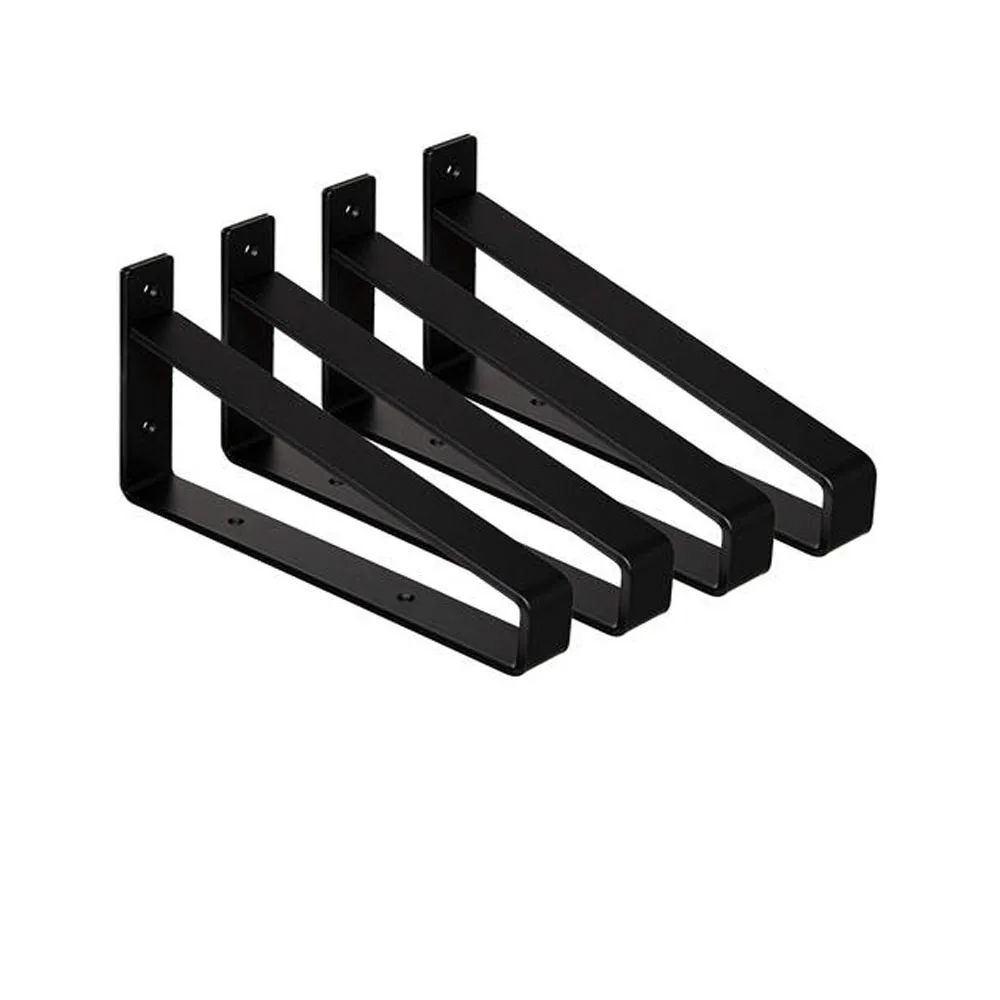

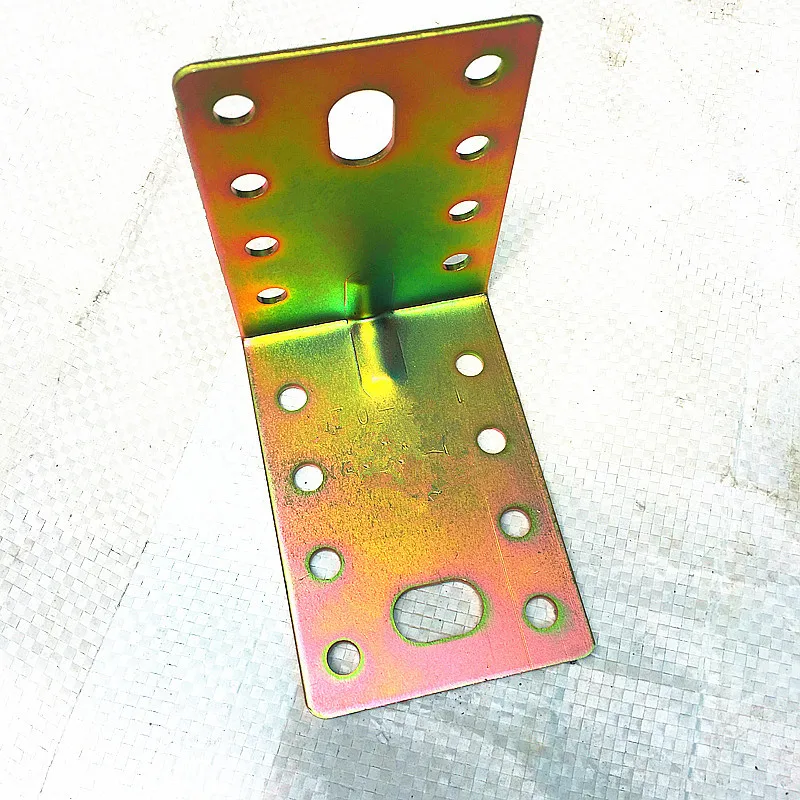

Пользовательские Монтажный кронштейн антенны из нержавеющей стали Z образные монтажные кронштейны 3/4 отверстие

- Категория: >>>

- Поставщик: Dongguan Shuangxin Industry Co. Ltd.Dongguan Ltd.

Сохранить в закладки 1600747613642:

Описание и отзывы

Характеристики

Custom Mounting Bracket Antenna Stamping Fabrication 3/4 Hole Heavy Duty "Z" Shaped Bracket

| ITEMS | DETAILS |

| Available Manufacturing Materials | Carbon steel(cold rolled steel sheet, galvanized steel sheet or tube), stainless steel, copper, brass, aluminum,etc. |

| Surface treatment | All kinds of surface treatment is available, polishing, zinc plating, nickel plating, chrome plating, powder coating, phosphate coating. |

| Measurements | According to customer's design,drawing or sample. |

| Mould/tooling/die | 1. We make the toolings by ourselves according to customer's drawing or sample. 2. We send samples to customer to confirm first 3. Single stamping die can save the cost if the quantities are not large.But the produce time is a little slowly than progressive stamping die 4.Progressive die can save produce time for the large quantities products ,but the die's cost is expensive than single stamping die. |

| Confirm sample | If the first sample is not satisfied customer, we will modify the mould until customer satisfied. |

| Usage | Funiture hardware, electronic hardware, construction machinery parts, metal processing machinery etc. |

| Sale market | Europe, Middle east, America, Africa ,Suoth America etc. |

| Our Service | We will answer your email or inquiry within 12 hours |

|

1).We remain profitable and sustainable even through the current economic downturn, in part though our market diversification,and in part due to our conservative philosophy guiding the way we have done managed our business since 2000. |

2).We continue to offer innovative cost-reduction options at the design stage and value-added/value engineered cost savings for our customer's current products. |

3).We listen to our Customers and add systems,processes,equipment or facilities constantly to meet the needs and requests of our customers. |

4)While these key indicators are a "Given" today, we track, monitor and implement changes to always improve our goals as we strive to improve in everything we do. |

5)Our commitment to quality is backed up by third party certification to world class quality standard ISO/TS 16949:2002. We offer the global OEM market quality distinction in manufacturing,innovative & engineering. |

Company Mission Statement |

"Support our customers by providing innovative,cost effective, engineered solutions,prototypes, components and assemblies, enabling our respective business partners to achieve superior financial results and quality growth." |

Establish a challenging and enjoyable workplace environment to promote teamwork.

|

| |

| |

|

CNC Production Departments

Capabilitie | CNC Milling,CNC lathe/turning,CNC Turning with Live Tooling |

| Solidworks,STEP,IGS, AutoCAD,Etc. | |

Equipment Capacity | 25 sets 3 / 4 Axis CNC Milling ,30stes CNC lathe / turning machines;30 Sets Small CNC(Auto Lathe) Machines,1 Set High Flow Speed Polish Machine |

| Tolerance | 0.01~0.05mm |

Metal Stamping Departments

| Capabilities | Progressive / Fourslide stamping,In-die tapping | |

| Solidworks, STEP, IGS, AutoCAD,Professional manufacturing department for OEM / ODM Toolings/Moulds | ||

| Press Capacity | 10 to 250 tons,40 sets stamping machines | |

| Available Manufacturing Raw Material | Aluminum 5052 ,Carbon Steel,SPCC,Hot/Cold Rolled Steel; Hardened Steels, Brass/Copper, etc. | |

| Surface Treatment | Anodized, Plating,Power,Coating, deburring, heat treatment,Oxided,Mirror Polishing,Etc. | |

| Tolerance | 0.05~0.1mm | |

Fasteners Department

| Capabilities | Screws, Nuts, Bolts, Washers,Rivets etc. | |

| Standard and customized fasteners are all available | ||

| Equipment Capacity | 60 sets machines. | |

| Available Manufacturing Raw Material | Carbon Steel, Stainless Steel, Brass/Copper, Aluminum, etc. | |

| Surface Treatment | Plating,Anodized,Grinding ,Coating, deburring, heat treatment,Oxided,Etc. | |

| Tolerance | 0.05~0.1mm | |

CNC Spring Department

| Capabilities | Compression spring,Wire bend form spring/hook;Torsion spring,Extension spring,Spiral Spring,Battery Spring,Etc. | |

| Press Capacity | 18 sets machines | |

| Available Manufacturing Raw Material | Spring Steel, steel , stainless steel ,music wire or other available materail. | |

| Surface Treatment | Anodized, Plating,Grinding ,Coating, deburring, heat treatment,Oxided,Etc. | |

| Tolerance | 0.05~0.1mm | |

| Wire diameter | 0.004"(0.1mm)to 6.0"(6.0mm) | |

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

Payment Terms

Payment: T/T, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

Q1: What is the stamping parts?

Metal stamping can be applied to a variety of materials based on their unique metalworking qualities for a number of applications across a wide range of industries. Metal Stamping may require the forming and processing of base common metals to rare alloys for their application specific advantages. Some industries require the electrical or thermal conductivity of beryllium copper in areas such as aerospace, electrical, and the defense industry or the high strength application of steel and its many alloys for the automotive industry.

Q2:How do your company control the products' quality?

Well,as we all know that the quality comes first during the businesses with our customers that we always persist in “Quality is the life of enterprise.we are using the first confirmed cases, production inspection, packaging seized the entire combination to control products quality strictly.

Q3:Are you a manufacture company or trade company?

we are a professional hardware manufacture company with over 10 years history,we have our own factory with complete hardware produce equipments and professional engineers that we can produce out perfectly products according to your requirements.

Q4:How about your products' price?

Well, we are insisting on the "win-win" principle.With the most advantageous price,to help our clients to gain more market share, so as to win more business.

Q5: How to order?

(1)You send us drawing or sample;(2)We carry through project assessment;(3)We give you a design;(4)You think the design is ok;(5)We make the sample and send it to you;(6)You think the sample is good then place an order and pay us 30% deposit;(7)We start to make the product;(8)When the goods is done, we deliver it to Shengzhen Yiantian;(9)You pay us the balance after you see the B/L Copy;(10)The whole order is done,thank you!

Q6:How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now.......

Похожие товары

Оптовая продажа кронштейн для большой грузоподъемности

Сверхпрочный кронштейн для настенной полки треугольный металлический держатель в гостиной спальне новой квадратной тубе золотистый плавающий

6 дюймов аксессуары для шкафа невидимые плавающие настенные полки поддержка скрытая кронштейн скрытой 2 упаковки

Настенные кронштейны на заказ скрытая опора плавающая полка кронштейн полки металлические поддержка сверхпрочных металлических черных цветов

Прямая поставка с завода нержавеющая сталь вешалка стальная вытяжная кронштейн деревянные строительные соединители

Многофункциональные Треугольные металлические мебельные Угловые скобы из нержавеющей стали

Низкая цена индивидуальный угловой кронштейн с порошковым покрытием железный Z-образный тремя отверстиями

Новые поступления

Новинки товаров от производителей по оптовым ценам