Прецизионная литьевая форма пластиковая форма/изготовление алюминиевых форм китайский производитель пластиковые литьевые

- Категория: Moulds >>>

- Поставщик: Shenzhen Ydyp Technology Co. Ltd.

Сохранить в закладки 1600748556077:

Описание и отзывы

Характеристики

customized high precision plastic mould products maker injection mold manufacturer mouldings for factory

SHENZHEN YOUDONY YOUPING TECHNOLOGY Co.,LTD

Excitingparts Mould Co.,Limited Located in Shenzhen China.

Our company has In-house prototype and tooling workshop- fully equipped 6000 square feet tool room,making sure your molds making in house,providing free mold routine maintenance,and also mold repair work if you need.

Meanwhile 90 ton - 1600 ton injection molding machines 20 sets,30000 square feet injection molding room including 250 square feet M7 class clean room.

If you have any plastic related product need to make,please feel free to email me Charles@ yd-yp.cn

www.excitingparts.com

Injection Molding workshop

Excitingparts has 90 ton - 1600 ton injection molding machines 100 sets,14000 square feet injection molding room

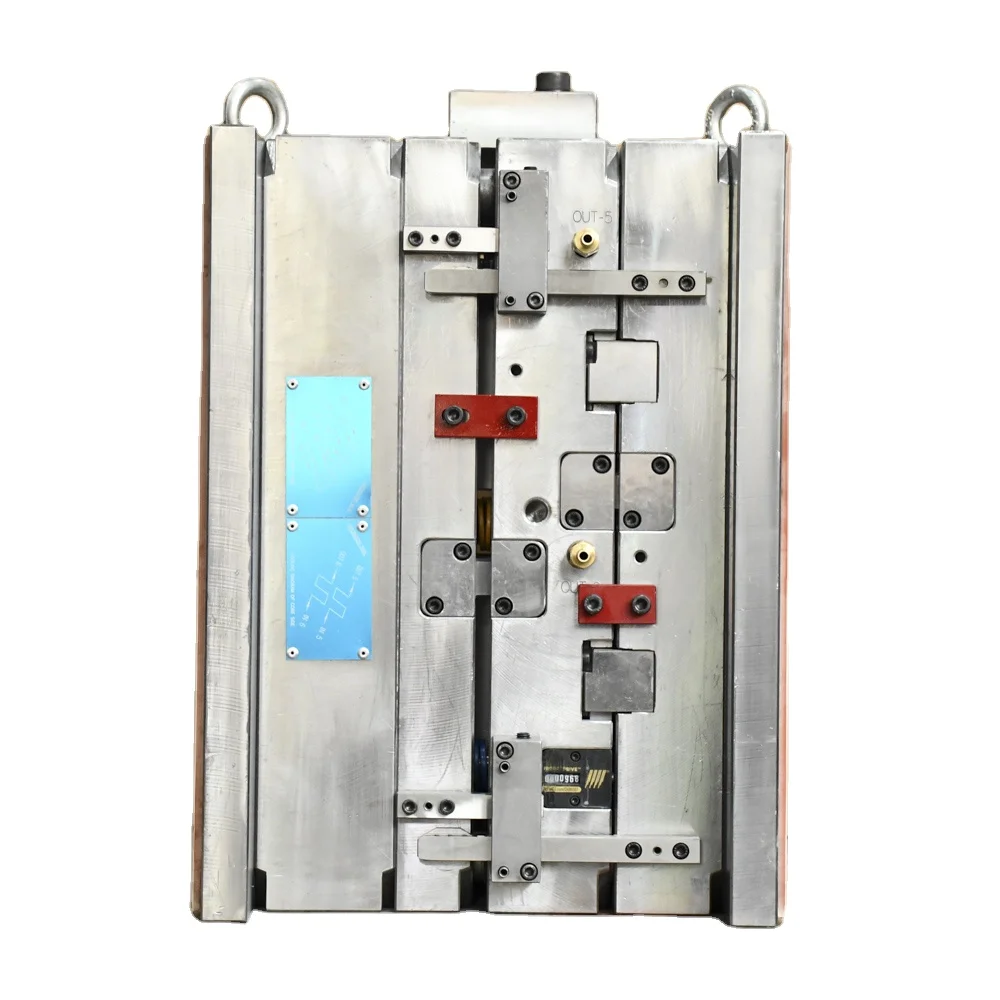

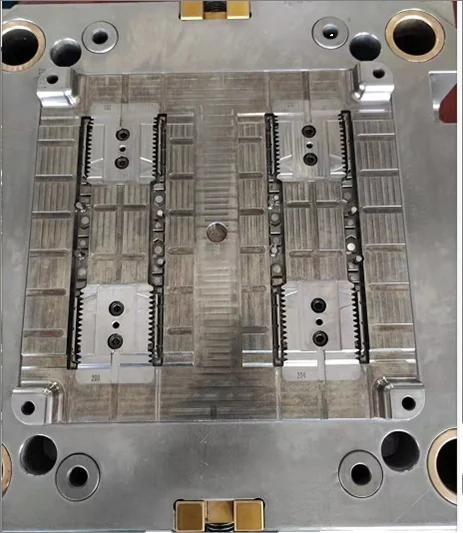

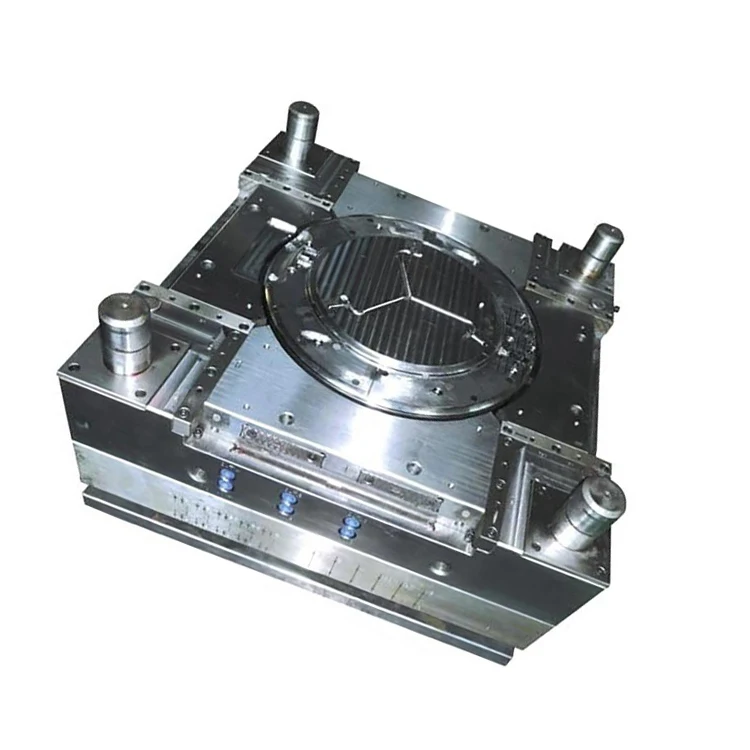

Mold Making workshop

Excitingparts has In-house tooling - fully equipped 6000 square feet tool room,making sure your molds making in house,providing free mold routine maintenance,and also mold repair work if you need.

Team

1, Why choose Excitingparts?

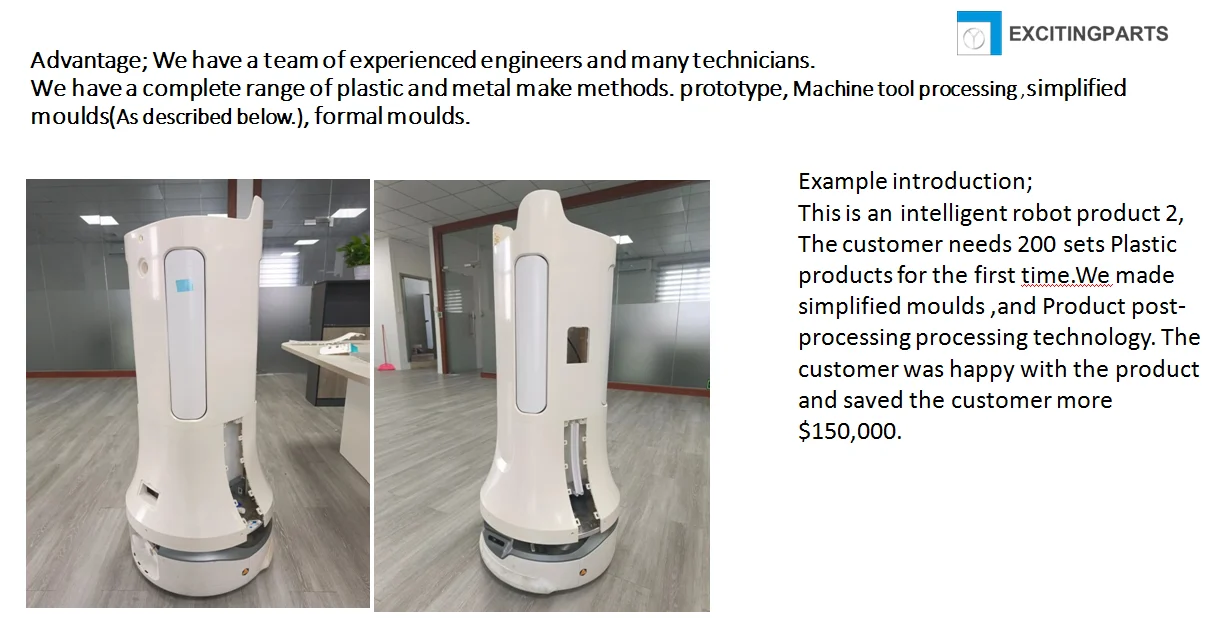

Prompt Reply;Professional Team Save cost for customers with high quality;OEM/ODM customized according to your requirement; Wide services.

2:What is your terms of payment?

50% Mold cost deposit,balance mold cost +50% production cost paid when samples confimed,Balance production cost paid against copy of B/L. We accept T/T

3:Can you make the production mold with short run production?

Yes ,we can . we can make the production for any quantity you want.

4: Are samples free of charge?

We offer custom service, we can make prototype, simplified moulds, formal moulds.If it is formal mould,the first trial samples(5-10pcs)are free. They will be sent to you by DHL, FEDEX ,UPS or TNT ).

5. How about your delivery time?

Generally, it take 40 days ( 30 days do mold and 10 days do mass production).

1,Plastic and metal parts;We are a OEM manufacturer, According to your requirements and the quantity of products,we can choose CNC, Lathe, milling machine make, prototype, simplified moulds, formal moulds.

2,Mould design; Use NX, Auto CAD , CATIA and other design software. Adopting standard prarametric design to optimize mold structure & processing process.

Use Autodesk mold-Flow for professional mold flow analysis.

ERP management system for mould design, manufacturing & testing. We have a good technical team with many experienced engineers .

Professional mould-Flow analysis team.

Professional DFM analysis team.

3,Project management;In the mold industry, better understand Chinese mold suppliers than customers in North America and Europe; better understand customer expectations and standards in North America and Europe than Chinese mold suppliers.

The Exctingparts-Mold project management team will provide project management services to customers in North America and Europe, serving as the customer's "eyes" in China to understand the true conditions of each mold from Chinese supplier.

We are committed to helping customers dig and demand building details from mold suppliers at every step of the process.

Contact Information:

Похожие товары

Изготовитель пресс-форм OEM под заказ гидравлический пресс компрессионный резиновый молдинг для резиновых

Высококачественная пресс-форма для литья под давлением изготовленная на заказ часть из АБС-пластика поставщик

Индивидуально изготовленный токарный станок с ЧПУ для быстрого прототипирования, точная обработка, нержавеющая сталь, медь, латунь, алюминиевый сплав

Инструменты для ухода за полостью рта стандартные инструменты имплантации зубов коробка инструментов из титанового

Изготовленные на заказ пластиковые детали для литья под давлением высококачественный производитель

Лидер продаж пресс-форма для литья под давлением ПЭТ

Гибочные инструменты и Гибочная форма/верхняя штамповочная пресс-форма для

Новые поступления

Новинки товаров от производителей по оптовым ценам