Химический смесительный резервуар из нержавеющей стали 316L

- Категория: Reactors >>>

- Поставщик: Zhengzhou Mino Scientific Instruments Co. Ltd.

Сохранить в закладки 1600764440261:

Описание и отзывы

Характеристики

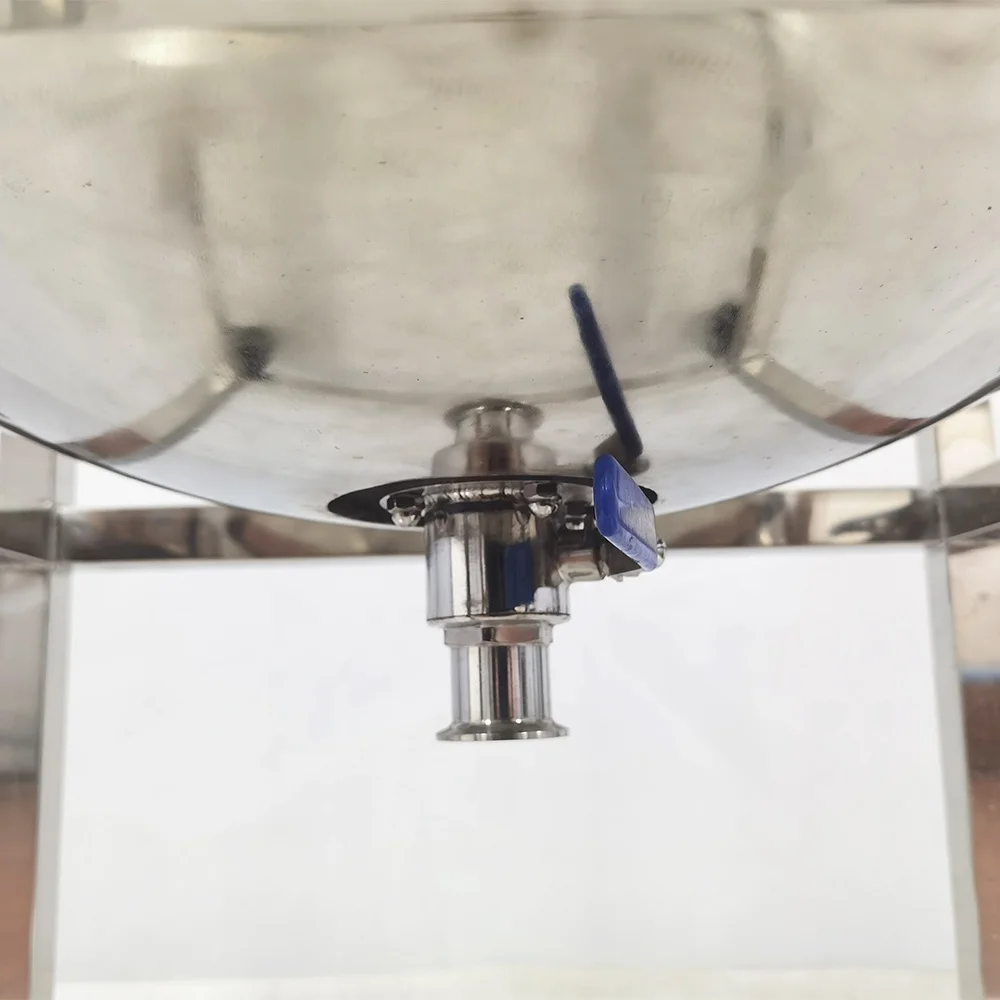

Chemical 316L 316 Stainless Steel Jacketed Reactor Mixing Vessel Tank

A stainless steel jacketed reactor is a type of vessel used in the chemical, and food processing industries for carrying out various chemical reactions, mixing, and blending processes. The reactor is made of high-grade stainless steel and features a jacketed design, which means it has an outer shell surrounding the inner vessel that is used to control the temperature of the contents inside.

Stainless steel jacketed reactors are ideal for processes that require precise temperature control, as the jacket can be filled with a heating or cooling medium, such as water or oil, to maintain the desired temperature. This makes them useful in a wide range of applications, including chemical synthesis, fermentation, polymerization, and crystallization.

Some of the specific uses of stainless steel jacketed reactors include:

Chemical synthesis: The reactor can be used to carry out chemical reactions that require precise temperature control, such as hydrogenation, oxidation, and esterification.

Fermentation: The jacketed design of the reactor is ideal for the growth and maintenance of microorganisms, making it useful for fermentation processes in the production of various products such as antibiotics, enzymes, and biofuels.

Polymerization: Stainless steel jacketed reactors are commonly used in the production of polymers and plastics, as they can maintain the precise temperature required for the reaction to occur.

Crystallization: The jacketed design of the reactor can be used to control the cooling and crystallization process of certain compounds.

Overall, stainless steel jacketed reactors are versatile vessels used in various industrial processes that require precise temperature control and high-quality materials to ensure product purity and safety.

| 1L~5L Jacketed Stainless Steel Reactor | ||||

| Model | BSF-1L | BSF-2L | BSF-3L | BSF-5L |

| Reaction Flask | 1L | 2L | 3L | 5L |

| Jacket Volume | 0.6L | |||

| Motor Power | 120W | |||

Port Number on The Lid | 6 or Customized | |||

Constant Pressure Drop Funnel | 500ml | |||

Rotating Speed | 0-600rmp | |||

| Reachable Vacuum | -0.098MPA | |||

| Power Supply | 220V / 50Hz or Customized | |||

| Material | Stainless Steel 316/304 | |||

| 10L~100L Jacketed Stainless Steel Reactor | |||||

| Model | BSF-10L | BSF-20L | BSF-30L | BSF-50L | BSF-100L |

| Reaction Flask | 10L | 20L | 30L | 50L | 100L |

| Overall Dimension | 480mm*480mm *1560mm | 500mm*500mm *1850mm | 530mm*530mm *1900mm | 580mm*580mm *2100mm | 1050mm*690mm *2350mm |

| Motor Power | 200W(1:3) | ||||

Port Number on The Lid | 8 or Customized | ||||

Temperature Range | -120℃~260℃ | ||||

Constant Pressure Drop Funnel | 1000ml | 2000ml | |||

| Charging Port | φ35 | ||||

| Power Supply | 220V / 50Hz or Customized | ||||

| Material | Stainless Steel 316/304 | ||||

Thickness of Stainless Steel | φ3 | φ4 | |||

Похожие товары

Химический смесительный реакционный чайник для обработки краски 500L-10000L высокопроизводительный реактор из нержавеющей

Надежная работа реактора PFR с PTFE

Лабораторный однослойный плоский фланец с открытым горлышком отдельный цилиндрический Сферический одногорловой стеклянный реакционный чайник двумя

Хорошее качество высокого давления водородный биодизельный Бак

Реактор гидротермального синтеза автоклав из нержавеющей

Цена по прейскуранту завода-изготовителя с двойными стенками S212-20L реактор покрытый кожухом фильтр боросиликатного

Gg-17 ( 3.3 ) боросиликатного стекла, стеклянный реактор 50l с рефлюкс блок

Новые поступления

Новинки товаров от производителей по оптовым ценам