Лидер продаж термопластичный вулканизированный материал ТПВ/ТПЭ пластмассовое сырье ТПЭ/ТПВ композитная резина для проводов и

- Категория: Thermoplastic Elastomers >>>

- Поставщик: Henan Hongke New Material Technology Co. Ltd.

Сохранить в закладки 1600788863070:

Описание и отзывы

Характеристики

Product Description

Details Images

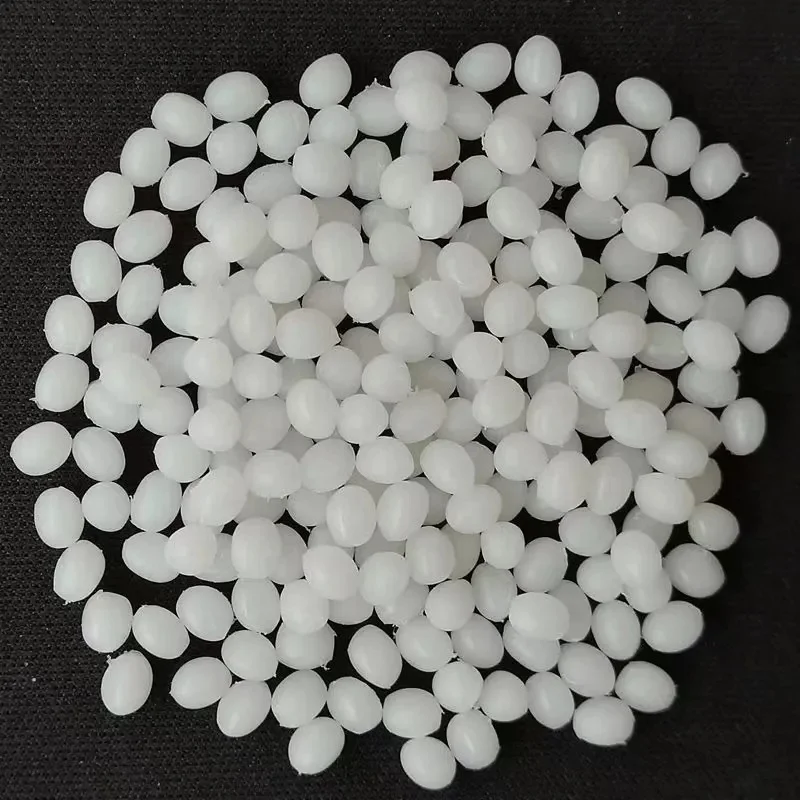

TPE RESIN

TPE (Thermoplastic Elastomer) is a thermoplastic elastomer material with the characteristics of high strength, high resilience,injection molding processability, wide application range, environmental protection, non-toxicity and safety, and excellent colorability. Thermoplastic elastomers have both the processing properties of thermoplastics and the physical properties of vulcanized rubber, which can be described as an advantageous combination of the advantages of plastics and rubber. Thermoplastic elastomers are taking over what was once only vulcanized rubber.

It’s soft, weather resistance, fatigue resistance and wide temperature service range, excellent processing performance, no need for vulcanization, recyclable, can be secondary injection molding, coated with PP, PE, PC, PS, ABS and other matrix materials. It can also be formed separately.

It’s soft, weather resistance, fatigue resistance and wide temperature service range, excellent processing performance, no need for vulcanization, recyclable, can be secondary injection molding, coated with PP, PE, PC, PS, ABS and other matrix materials. It can also be formed separately.

Product Features:

1. It can be processed by general thermoplastic molding machine without special processing equipment.

2. The production efficiency has been greatly improved. It can be directly injection molded by rubber injection molding machine. Since vulcanization is not required, the molding time is very short. It can be directly produced and processed by the extruder, and the production efficiency is greatly improved.

3. Easy to recycle and reduce cost. The wastes generated in the production process (burrs escaping, extruded waste rubber) and the final waste products can be directly returned for reuse; Used TPE old products can be recycled after simple regeneration, reducing environmental pollution and expanding the source of renewable resources.

4. Energy saving. Most thermoplastic elastomers do not need curing or curing time is very short, which can effectively save energy. Take the energy consumption of high-pressure hose production as an example: the rubber is 188mj / kg, and the TPE is 144mj / kg, which can save more than 25%.

Product performance: good transparency, elasticity and relatively low price, with wide design space and wide hardness range, from super soft to 90a. Excellent transparency, gloss and comfortable hand feel, widely used in adult products. It has good UV resistance, weather resistance and high temperature resistance, and has been used outdoors for a long time.

2. The production efficiency has been greatly improved. It can be directly injection molded by rubber injection molding machine. Since vulcanization is not required, the molding time is very short. It can be directly produced and processed by the extruder, and the production efficiency is greatly improved.

3. Easy to recycle and reduce cost. The wastes generated in the production process (burrs escaping, extruded waste rubber) and the final waste products can be directly returned for reuse; Used TPE old products can be recycled after simple regeneration, reducing environmental pollution and expanding the source of renewable resources.

4. Energy saving. Most thermoplastic elastomers do not need curing or curing time is very short, which can effectively save energy. Take the energy consumption of high-pressure hose production as an example: the rubber is 188mj / kg, and the TPE is 144mj / kg, which can save more than 25%.

Product performance: good transparency, elasticity and relatively low price, with wide design space and wide hardness range, from super soft to 90a. Excellent transparency, gloss and comfortable hand feel, widely used in adult products. It has good UV resistance, weather resistance and high temperature resistance, and has been used outdoors for a long time.

Scope of application

Application:

Sports shoes, travel shoes, ski boots, hiking boots and other sporting goods wire cable and golf leather Industrial rubber products such as hoses, tapes, and rubber sheets.

Transmission belt, conveyor belt Waterproof membrane, film, raincoat.

High-grade, high-transparency toys, adult products, suction cup materials, sports equipment and sealing rings, etc.

Home appliance shells, handles, etc.

All kinds of stationery, toys, daily supplies, etc.

Car bumpers, dashboards, steering wheels, wiper strips, gears, etc.

Plastic surgery appliances, plaster substitutes

Transmission belt, conveyor belt Waterproof membrane, film, raincoat.

High-grade, high-transparency toys, adult products, suction cup materials, sports equipment and sealing rings, etc.

Home appliance shells, handles, etc.

All kinds of stationery, toys, daily supplies, etc.

Car bumpers, dashboards, steering wheels, wiper strips, gears, etc.

Plastic surgery appliances, plaster substitutes

Product Paramenters

Commodity | TPE30C | Quality inspection date | |||||

Item | Unit | Standard | Determine scope | Testing result | Test method | ||

Appearance | Visual test | Natural color | Natural color | ||||

Hardness | Shore A | ASTM-D2240 | 0~100 | 30C | indoor temperature | ||

Density | SP.Gr | ASTM-792 | 1.15±0.05 | 1.2 | |||

Solution flow index | g/10min | ASTM-D1238 | 5-20 | 13 | |||

Tensile strength | Mpa | ASTM-D412 | ≥5 | 7.8 | indoor temperature 500mm/min | ||

Elongation | % | ASTM-D412 | ≥500 | 550 | |||

Teat strength | KN/m | ASTM-D624 | ≥20 | 23 | |||

Manufacturing technique | ||||

Barrel temperature | Range ℃ | Typical value ℃ | ||

Forepart | 150-190 | 170 | ||

Midpiece | 150-210 | 180 | ||

Back end | 150-210 | 180 | ||

Orifice/Die-head | 160-200 | 180 | ||

Upper limit of processing temperature ℃ | 220 | |||

Time of drying | Generally there is no need to dry,If the storage environment is humid or the production of products surface requirements higher parts,dry in a hot air oven for 2 to 4 hours | |||

1.The above data is only for reference. The above data can be adjusted according to different models,molds and product requirements. 2.Do not allow the material in the barrel to stay too long too long,Please use PE to clean the machine before stopping it. | ||||

Company Profile

Henan Hongke New Material Technology Co., Ltd. is located in Zhengzhou City, Henan Province, an important industrial town in China. Our company is a dynamic modern industrial enterprise dedicated to the research, development, production and sales of plastic particles, with advanced equipment, strong technical strength, and an annual production of 10000 tons.The products have been exported to all regions of China and have been obtained in many countries and regions around the world

Our products including PP/PC/PVC/ABS,LDPE/LLDPE/HDPE//EVA and so on.The company's products are widely used in many fields such as waterproof coiled materials, modification, pipes, blowing films, handicrafts, etc. The company has advanced plm, erp, scm and crm management systems to ensure that customers have no worries in the whole process of product consultation, procurement, ordering and use!

Our company wins the trust and favor of our customers by virtue of high-quality products, good services and ultra-low prices, so that our products are spread all over the country and abroad! Thanks to the support of new and old customers, we will work harder and make progress, and give back to our customers with good service! Your satisfied smile is our eternal pursuit!

Our products including PP/PC/PVC/ABS,LDPE/LLDPE/HDPE//EVA and so on.The company's products are widely used in many fields such as waterproof coiled materials, modification, pipes, blowing films, handicrafts, etc. The company has advanced plm, erp, scm and crm management systems to ensure that customers have no worries in the whole process of product consultation, procurement, ordering and use!

Our company wins the trust and favor of our customers by virtue of high-quality products, good services and ultra-low prices, so that our products are spread all over the country and abroad! Thanks to the support of new and old customers, we will work harder and make progress, and give back to our customers with good service! Your satisfied smile is our eternal pursuit!

Certifications

Packing & Delivery

FAQ

1. who are we?

We are based in Henan, China, start from 2023,sell to North America(20.00%),South America(20.00%),Eastern Europe(20.00%),Oceania(18.00%),Africa(10.00%),Mid East(7.00%),Southeast Asia(5.00%). There are total about 11-50 people in our office.

2. Can you provide samples?

Always We can provide you with free samples, you only need to bear the freight.

3.How about your price?

Although our products are brand-name products, our prices are very favorable and competitive. Customers from all over the world are willing to purchase our products because of our competitive price

4. How long is your delivery time?

Generally it is 10 days if the goods are in stock. Or it is 30 days if the goods are not in stock, it is according to quantity.

5. What is your terms of payment?

We accept LC and TT both. If the total price is below $3000, you must pay in full. If it's over $3000, you must pay 30% in advance, and the balance before shipment

We are based in Henan, China, start from 2023,sell to North America(20.00%),South America(20.00%),Eastern Europe(20.00%),Oceania(18.00%),Africa(10.00%),Mid East(7.00%),Southeast Asia(5.00%). There are total about 11-50 people in our office.

2. Can you provide samples?

Always We can provide you with free samples, you only need to bear the freight.

3.How about your price?

Although our products are brand-name products, our prices are very favorable and competitive. Customers from all over the world are willing to purchase our products because of our competitive price

4. How long is your delivery time?

Generally it is 10 days if the goods are in stock. Or it is 30 days if the goods are not in stock, it is according to quantity.

5. What is your terms of payment?

We accept LC and TT both. If the total price is below $3000, you must pay in full. If it's over $3000, you must pay 30% in advance, and the balance before shipment

Accepted Delivery Terms: FOB,CIF,DDP;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C;

Похожие товары

Тайваньская добавка h функциональная маточная смесь из переработанного ТПУ

Полиэтилен высокой плотности HDPE сырье гранулы

1,50 $ - 2,00 $

1330 мм * 200 м прозрачная tpu сырье Защитная пленка для экрана мобильного

5,00 $ - 9,00 $

CNMI Sinopec производитель прямой яркий нейлон 6 чипов для тонкой

1,90 $ - 2,00 $

2023 Новый 4028 телефон гибкий провод огнестойкий анти УФ маслостойкий компоненты бытовой техники и

Шланг/пневматическая труба сырье из термопластичных полиуретановых

2,10 $

Состав термопластичного эластомера ТПЭ/ТПВ

2 980,00 $ - 3 680,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $