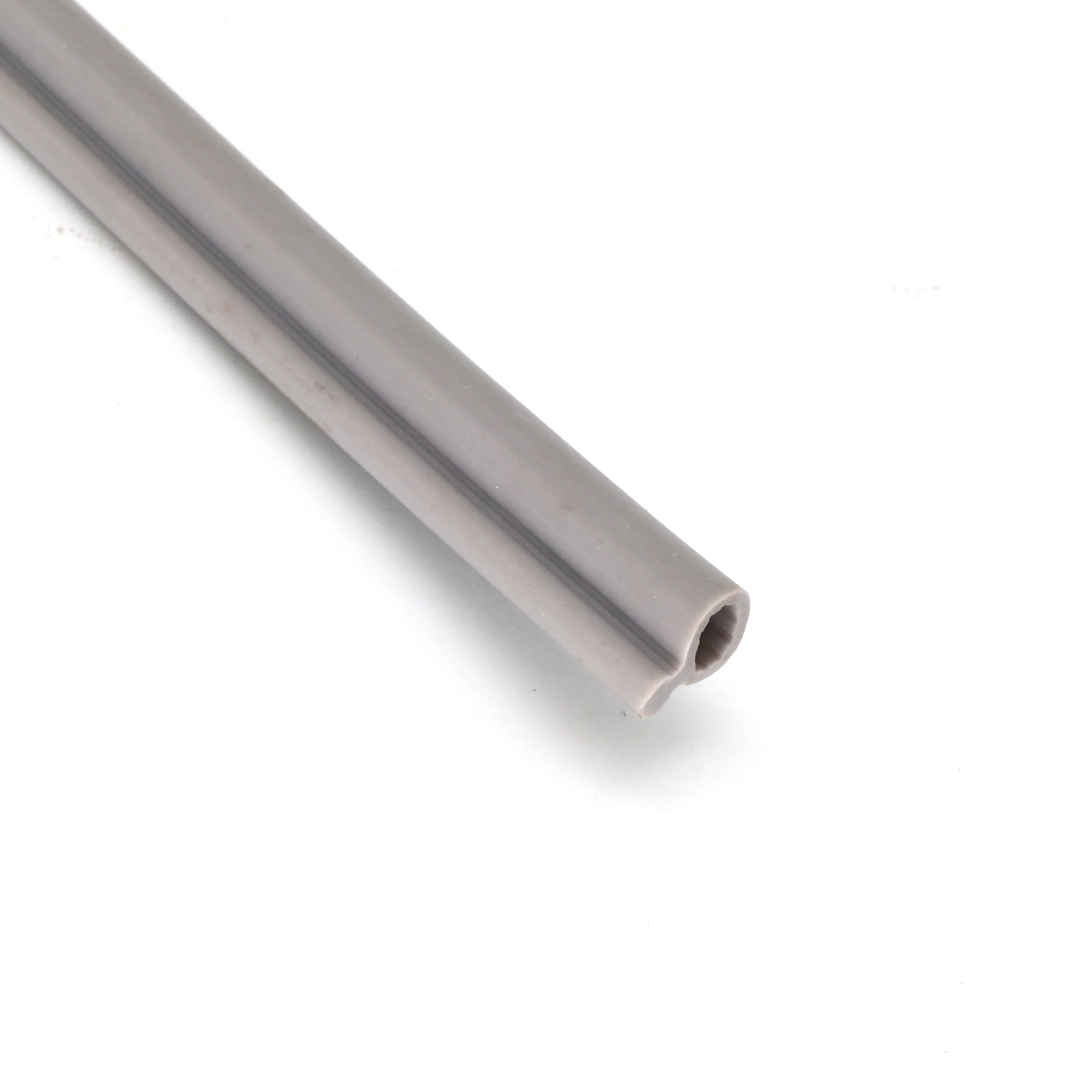

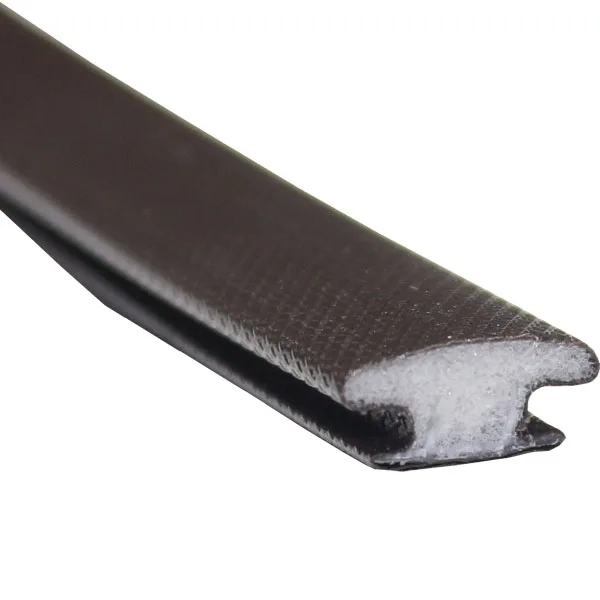

Цвет и размер могут быть изготовлены по индивидуальному заказу огнестойкий ПВХ край резиновый материал для бокового уплотнения гаражной двери

- Категория: >>>

- Поставщик: Hangzhou Biyou Building Materials Technology Co. Ltd.

Сохранить в закладки 1600802007356:

Описание и отзывы

Характеристики

PRODUCT DESCRIPTION

Components

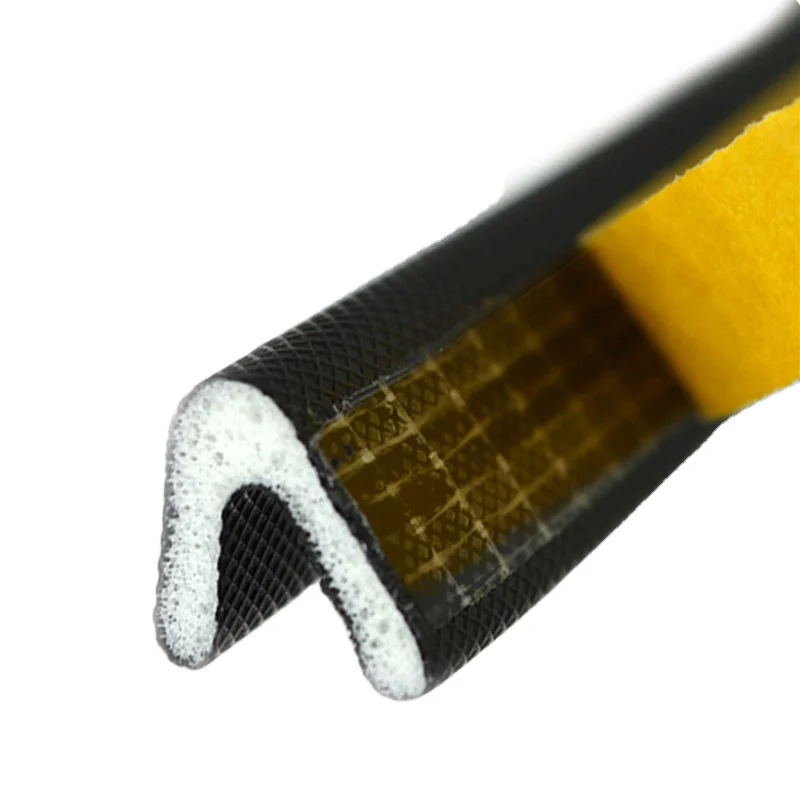

* Polyurethane (PU) foam core – high durability, superior recovery performance

* Polyethylene (PE) film – weather and UV-resistant

* polypropylene (PP) insert – prevents elongation and shrinkage

* Smooth or embossed exterior, resistant to contamination

* Compatible with cleaning agents

* Polyethylene (PE) film – weather and UV-resistant

* polypropylene (PP) insert – prevents elongation and shrinkage

* Smooth or embossed exterior, resistant to contamination

* Compatible with cleaning agents

Ultimate benefits

* Excellent memory - returns to original shape after compression

* Stability - low/no stretch gained by rigid insert

* Easily compressed - low compression force, unaffected by temperature variance

* Acoustics - outstanding acoustic performance

* Thermal conductivity - unrivalled thermal performance

* Paint and stain proof - properties unaffected by standard paints and stains

* Stabilized - unaffected by rot, fungi, UV-light or ozone

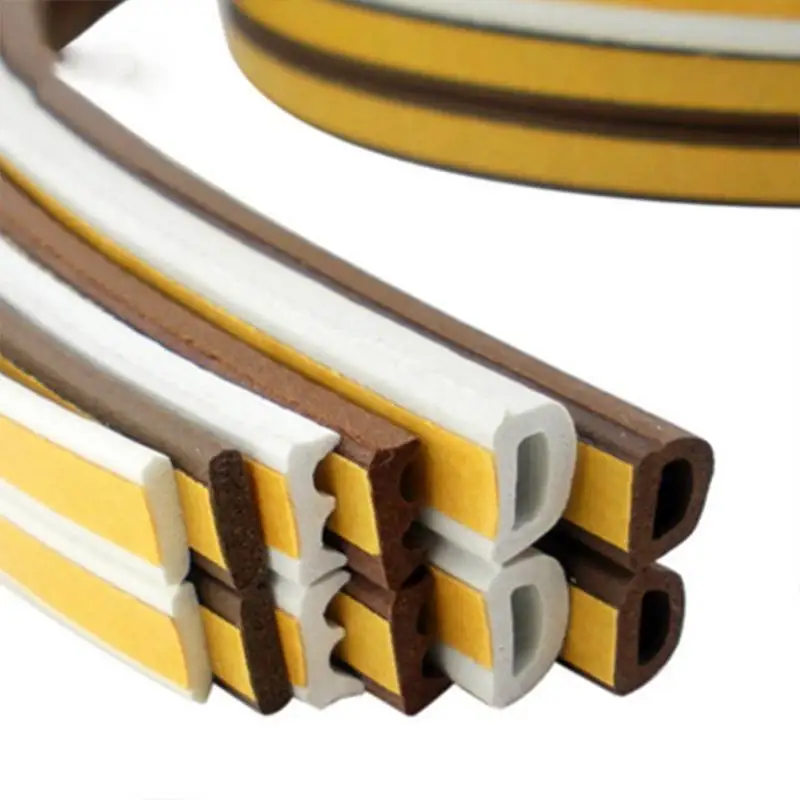

* Colors - white, black, brown, grey and many other options

* Temperatures - wide operating range under extremely cold and warm weather conditions

* Stability - low/no stretch gained by rigid insert

* Easily compressed - low compression force, unaffected by temperature variance

* Acoustics - outstanding acoustic performance

* Thermal conductivity - unrivalled thermal performance

* Paint and stain proof - properties unaffected by standard paints and stains

* Stabilized - unaffected by rot, fungi, UV-light or ozone

* Colors - white, black, brown, grey and many other options

* Temperatures - wide operating range under extremely cold and warm weather conditions

Applications

* For universal flat surfaces

* For timber windows and entry doors

* For PVCu windows and doors

* For Aluminum windows and doors

* For internal door and furniture applications, internal timber doors and sliding wardrobe, closet and sideboard doors

* For universal flat surfaces

* For timber windows and entry doors

* For PVCu windows and doors

* For Aluminum windows and doors

* For internal door and furniture applications, internal timber doors and sliding wardrobe, closet and sideboard doors

Technical Data Sheet

Compression set

<15% after 1 hour relief of 50% compression at 70℃ and 24 hours

<15% after 1 hour relief of 50% compression at 70℃ and 24 hours

Compression force

approx. 15N at 25% compression per 100mm, <10N for lip profiles Test temperature -60℃ to +70℃

Heat conductivity

0,014 W/km at 0℃

Long life performance

no change of length-related and partial joint permeability

Paint compatibility

no adhesion, no hardening, no discoloration

Acoustic testing

43 dB at a window IV68 with a center seal

43 dB at a window IV76 with center and overlap seals

Weather-resistance

tested up to 20 years

Heat conductivity

0,014 W/km at 0℃

Long life performance

no change of length-related and partial joint permeability

Paint compatibility

no adhesion, no hardening, no discoloration

Acoustic testing

43 dB at a window IV68 with a center seal

43 dB at a window IV76 with center and overlap seals

Weather-resistance

tested up to 20 years

Ozone resistance

rack stage 0

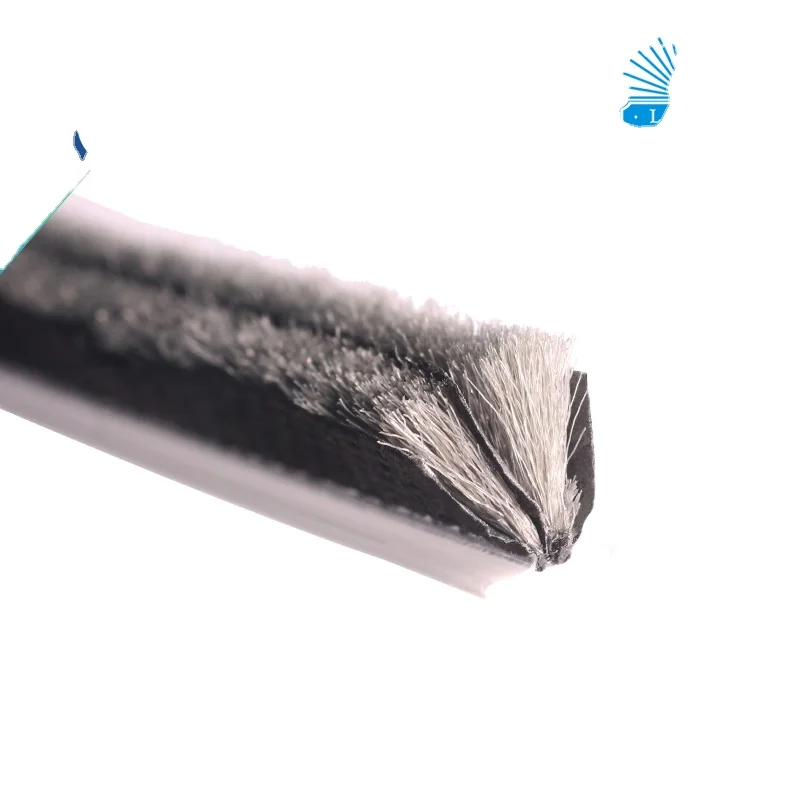

Abrasion resistance

no abrasion after 285,000 cycles of grinding load.

no abrasion after 285,000 cycles of grinding load.

PRODUCT SHOWCASE

PRODUCT PACKAGE

COMPANY PROFILE

INTERNATIONAL TESTING

CERTIFICATE DISPLAY

PACKING & DELIVERY

FAQ

Q1. Are you a manufacturer or trading company?

We are a professional manufacturer for passive fire stopping products, acoustic and weather sealing system with more than 15 years’ experience.

Q2. Do you accept OEM or ODM?

Yes, We are professional in OEM and ODM. Now cooperating with famous brands for OEM & ODM.

Q3. What is payment term?

We prefer T/T, other ways should be confirmed first. For new customer, 30% advanced payment after order confirmation,70% balance payment before shipment.

Q4.Could you send me sample before I place an order?

Yes, we offer free samples for your evaluation; you provide the Courier account for freight collect.

Q5. What is your delivery time?

7-20 days according to your purchasing quantities.

Q6. How do you control the quality?

We will arrange sample confirmation before production. During the production, we have professional QC staffs control the quality and manufacture in accordance to your confirmed samples.

We are a professional manufacturer for passive fire stopping products, acoustic and weather sealing system with more than 15 years’ experience.

Q2. Do you accept OEM or ODM?

Yes, We are professional in OEM and ODM. Now cooperating with famous brands for OEM & ODM.

Q3. What is payment term?

We prefer T/T, other ways should be confirmed first. For new customer, 30% advanced payment after order confirmation,70% balance payment before shipment.

Q4.Could you send me sample before I place an order?

Yes, we offer free samples for your evaluation; you provide the Courier account for freight collect.

Q5. What is your delivery time?

7-20 days according to your purchasing quantities.

Q6. How do you control the quality?

We will arrange sample confirmation before production. During the production, we have professional QC staffs control the quality and manufacture in accordance to your confirmed samples.

Похожие товары

Хит продаж домашняя ветрозащитная и водонепроницаемая уплотнительная лента для дверного края

22,19 ₽ - 33,28 ₽

I-ECO 3111 самоклеящиеся V-образные пенополиуретановые зачистки для дверных шкафов дверные рамы защитные пломбы

23,30 ₽ - 27,74 ₽

HB283 современный дизайн правая перекошенная ручка без основания для наружного применения

265,12 ₽

Горячая Распродажа экструдированное основание Автоматическая вставка алюминиевых окон и дверей профиль Пыленепроницаемая противошумная укладка

Уплотнитель для двери уплотнитель звукоизоляционная V-образная пена погоды Большой зазор легко разрезать на размер

22,19 ₽ - 33,28 ₽

I-ECO 3106 из пенополиуретана самоклеящаяся уплотнительная лента для дверей с V-образным покрытием стеклянной уплотнительной ленты и окон

23,30 ₽ - 27,74 ₽

Высококачественная уплотнительная прокладка для двери

16,64 ₽ - 22,19 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Кокосовая стружка мягкая и сладкая на вкус без глютена запеченная Ароматизированная упаковка для приготовления пищи кондитерских

Медицинский одноразовый стерильный катетер

Эффективные акустические панели эффективные звукоизоляционные материалы для качественной

65% полиэстер/35% хлопок саржа TC камуфляжная ткань 220gsm с водонепроницаемым принтом

1,48-1,61 $

Органическое жидкое мыло для мытья рук оптом

0,66-1,46 $

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $