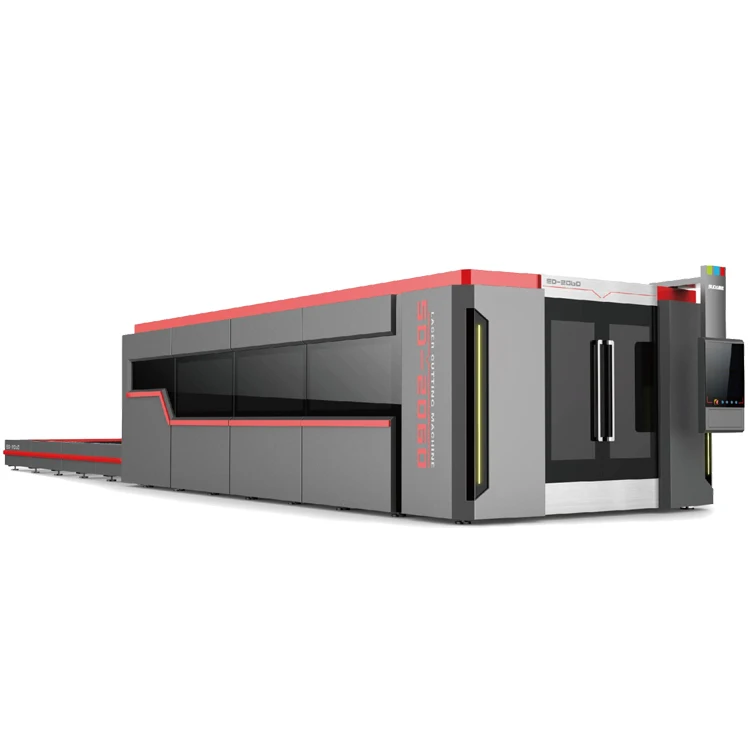

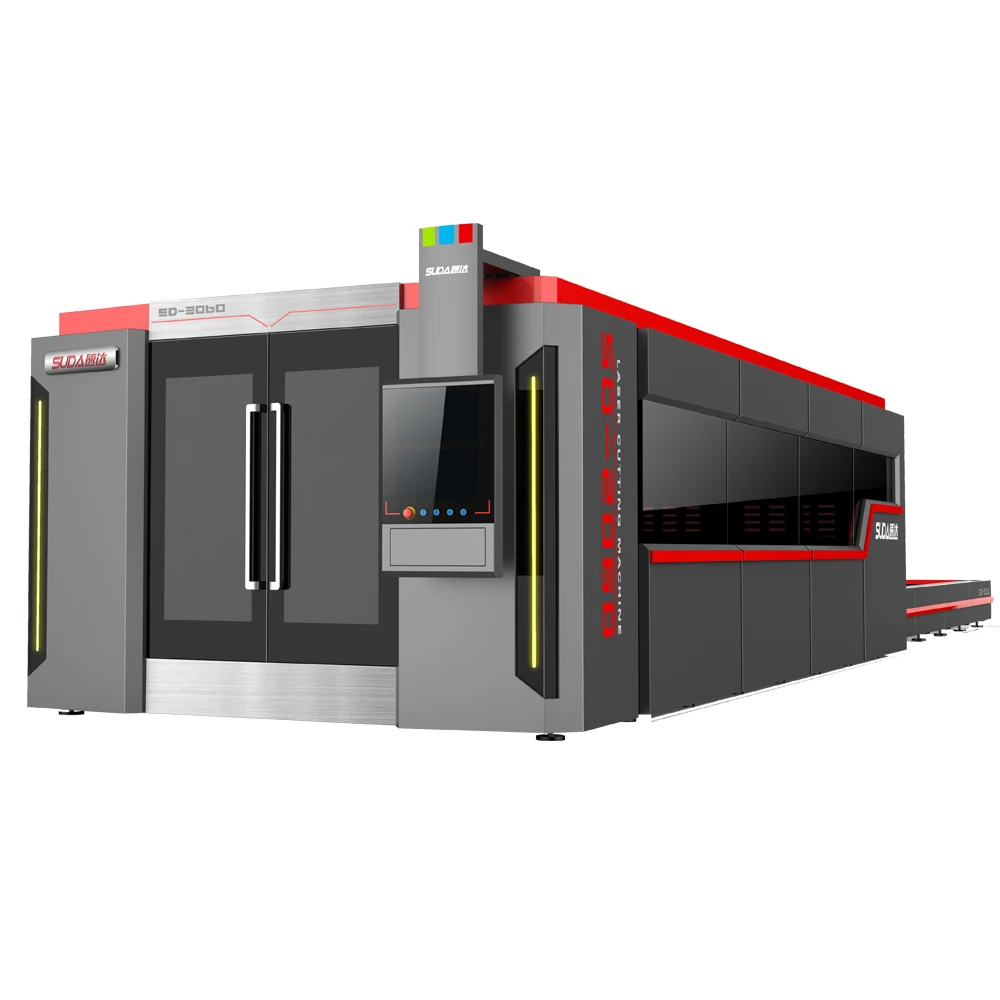

Быстрая доставка большая закрытая машина для волоконной лазерной резки резак металла и стали защитная крышка листового алюминия

- Категория: >>>

- Поставщик: Tongxing Technology Development Co. Ltd.

Сохранить в закладки 1600804220673:

Описание и отзывы

Характеристики

Configuration and Technical Data

◆Adopt industrial heavy duty steel structure,plate steel joint welding with square pipe steel,under heat treatment,will not deform after long time using.

◆Adopt NC pentahedron machining,milling,boring,tapping and other machining processes to ensure high processing accuracy.

◆Configure with Japan THK linear rail for all axis,to ensure durable and high precision for long time processing.

◆X,Y axis configure with high accuracy grinding type gear rack,Japan Shimpo reducer,high speed and precision can be ensured.Z axis is transmitted by high accuracy rolling ball screw.

◆Adopt France Schneider AC servo system,larger power,stronger torque force,working speed is more stable and faster.

◆Adopt Japan SMC intelligent gas group,dual gas control,automatic adjustment for gas type and gas software.

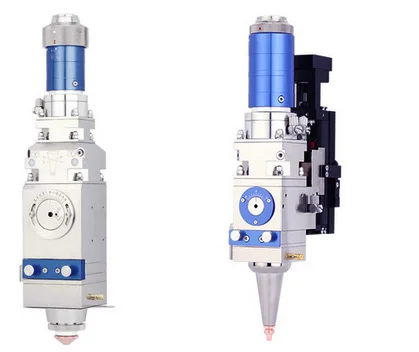

◆Adopt professional WSX,Raytools laser cutting head,imported optical lens,focus spot smaller,cutting lines more precise,higher efficiency and better processing quality can be ensured.

◆Configure with non-contact auto follow function,ensure the best focal length and cutting effect.

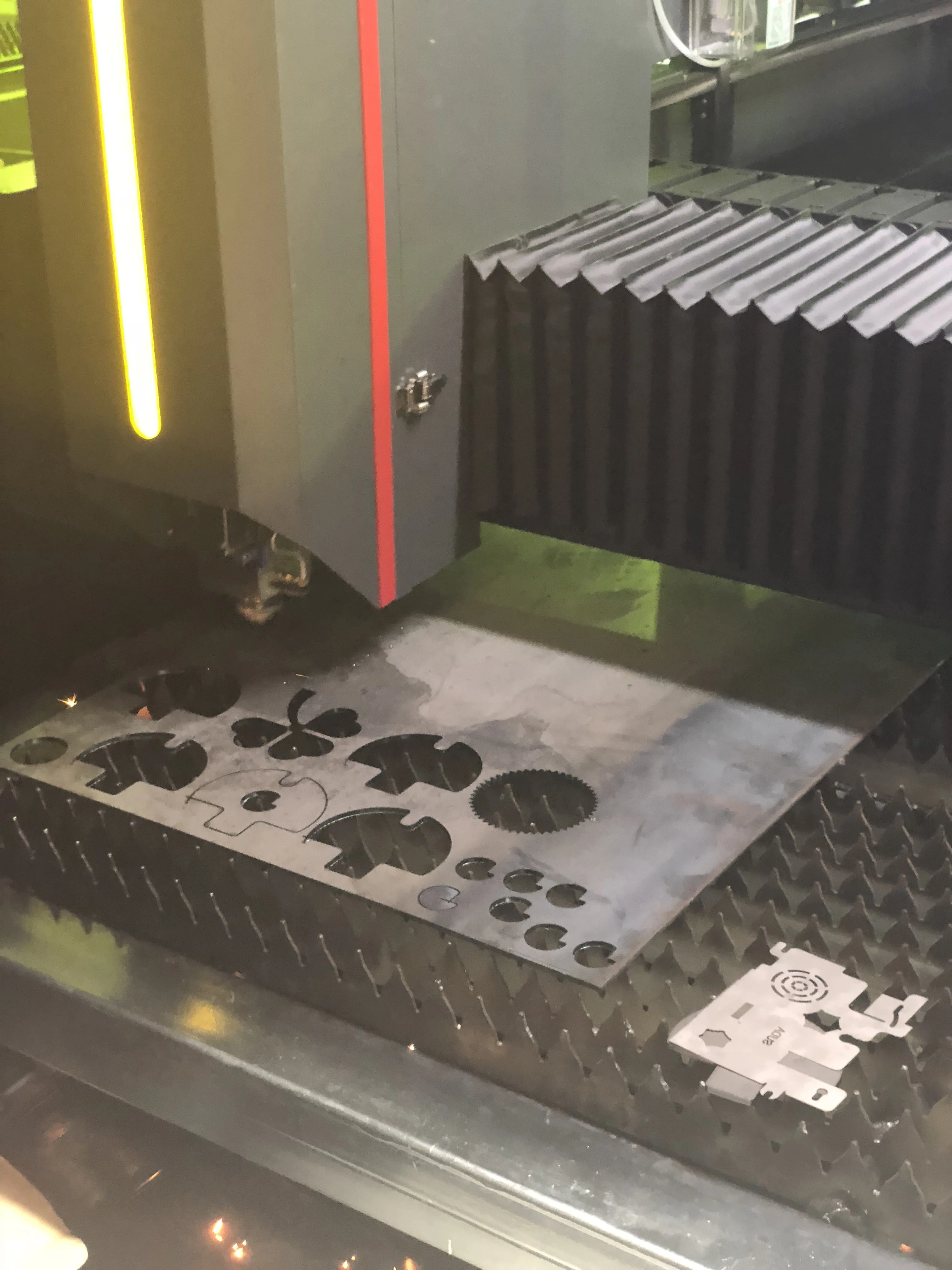

◆Fiber laser transmitting,flexible processing,realized high accuracy cutting on every point.

◆Professional laser cutting CNC controlling system,connected with computer,simple operation.

◆Configure with professional industrial chiller with double temperature control molds,high cooling efficiency and high transferring ratio of laser.

◆Compatible with multiple software,can design ant graphic and letters as you like,operating simple,flexible and easy.

◆Wide application:can be widely used in processing any stainless,carbon steel,alloy steel,silicon steel,spring steel,pickling steel plate,galvanized sheet,etc.

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | ||||

| \t | \t | ||||

| \t | \t | ||||

| \t | \t | ||||

| \t | \t | ||||

| \t | \t | ||||

| \t | \t | ||||

| \t | \t | ||||

| \t | \t | ||||

| \t | \t | ||||

| \t | \t | ||||

| \t | \t | ||||

| \t | \t | ||||

| \t | \t | ||||

| \t | \t | ||||

More heavy machine bed

More perfect structure design

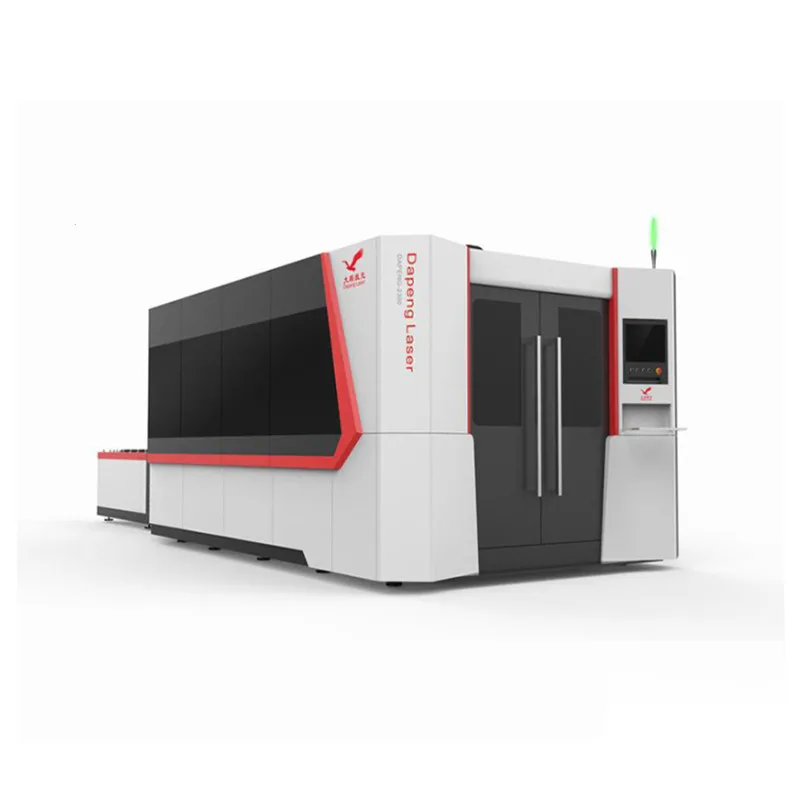

◆Detachable structure,can customize larger model

◆Function area reserved window,suitable for different configuration choice

Stronger protection

◆Whole cover structure,safer to use

◆Chain type transmitting mode,one key frequency conversion drive,more safe reloading

New shape and color

◆Meet industrial needs,more protective

◆More perfect shape design,color matching more in line with international standards

More Pictures

Machine Structure

The machine structure adopts industrial heavy steel structure, under heat treatment, suffer lower temperature tempering and annealing, won't deform after long time use. the machine base is very stable when the processing,

Japan THK Linear Rail and Block

The machine adopts the best linear and block rail from Japan. We have the feedback from our client that its block even can use over 10 years and can't break.

The usage lifespan and the product quality definitely can be ensured.

France Schneider Servo System

The fiber laser machine adopts the imported servo system from France including servo motor and servo driver, The Y axis two servo motor power are 2KW, The X axis servo power is 2KW power, The Z axis servo motor power is 0.4KW power.

CYPCUT Control System

The best control system in fiber laser machine industry,

It is suitably applied to high power fiber laser machine and can support the rotary device, exchange table and automatic focus cutting head.

S & A Chiller

Focus on the research and development of industrial cold machine, independent research and development of core parts strictly implement ISO production management system, With excellent quality and leading research retrength, S &A has become a leding enterprise in the domestic industrial refrigeration industry.

Raycus Laser Source

Japan Shimpo Servo Reducer

Our fiber laser machine adopts the Shimpo Servo Reducer from Japan with low noise when the machine is processing the metal materials,After many refinements,it has small size in installation but high precision function.

WSX Fiber Laser Cutting Head

Our fiber laser machine 1000 watt install the WSX NO:1 manual focus cutting head,

The machine also can optional the NC30 automatic focus cutting head, Fast perforation (especially the thick materials), The plate is not easy to heat, Does not affect the cutting head following.

SMC proportional valve

Used in high power fiber laser machine(normally over 1000w), processes thicker materials, it has a great cutting effects, if you use air compressor for the machine,it only can manually adjust ,not accuracy and cutting effect will be not well.

Oil Lubrication System

This machine accessory is applied to lubricate the

the machine rail and block in order that it runs smoothly and fast, improving the working efficiency.◆Applicable field: can be used for various metal sheet processing,mainly applicable for high-speed and high-precision cutting of stainless steel,carbon steel,manganese steel,galvanized sheet,alloy sheet and rare metal materials.

◆Applicable industries: hotel kitchen equipment,hardware products,automobile manufacturing,mechanical equipment,display equipment,precision parts,electrical equipment,elevator equipment,lighting hardware,automobile decoration and other industries.

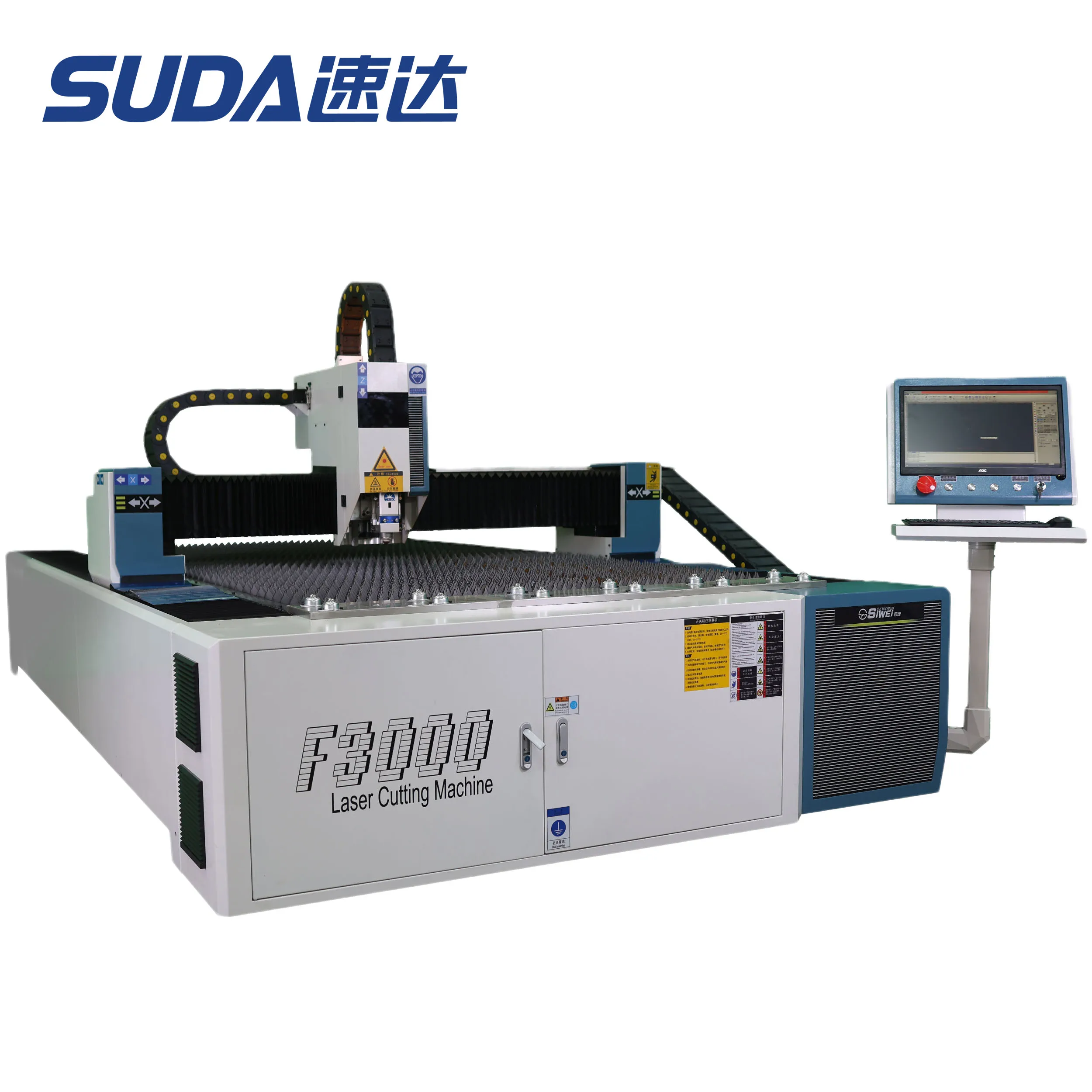

TONGXING Technology Development Co.,Ltd established in 1992,lies in HEFEl --One of Chinese scientific and technology cities.It has been working on researching and manufacturing CNC machinery in field of woodworking,stone engraving,metal processing,glass cutting and advertising etc. over 20 years. The main products: Heavy moving column CNC machining center,Heavy static column CNC machining center, High accuracy metal cutting machine, High precision fiber laser machine,Vanguard series CNC engraver, Multistage CNC machine center,SUDA high accuracy CNC engraver, SUDA laser cutting machine,fiber cutting machine,totally 23 series ,more than 100 models. The sales net not only covers all Chinese provinces and municipalities,including HongKong, Taiwan&Macao,also the products are exported to more than 120 countries and regions such as Europe,America,Middle-east,South-east Asia etc.

Certificate

Joint with global core suppliers

Pre-Sales Service

1. We have many exhibitions very year, hundreds of clients was coming to our booth for further communication.

2. 24-hours online Inquiry and consulting support.

3.Support sample testing .

4.We welcome you to visit our factory.

After-Sales Service

1. Training how to instal the machine, training how to use the machine online.

2. Engineers available to clients' factory for training.

3.Guarantee for one year

4.24-hour technical support by email or calling

5.User-friendly English manual for machine using and maintaining

6.Free technician training for customers.

We know for enterprises, quality is the life, so we have put the quality control into each link as products development, design, purchasing, processing, assembling and testing etc. Everybody in the company are participated into the quality management to prevent any unqualified products from being sent out.

We always pursue the service philosophy of "ALL FOR CUSTOMERS". The Advanced management system and perfect service system ensure that we can provide timely and efficient services and ensure product's stability in great extent, which supply a effective guarantee for the system normal operation.

Q1. how to get the most suitable machine and best price?

Please tell me

what's material you want to cutting or engraving ?

what's MAX size of carved material ?

Then I will recommend the most suitable model and the best price for you.

Q2. In case of failure,how to do?

Call us----our engineers are online for 24-hours,and ready to serve you.

Replacement of damaged parts for free---For more information,please contact us

The CD and operation manual----It show the most common failure in working processing and how to solve this problems.

Q3. What is the type of shipping and producing time?

we offer EXW, FOB and CIF which you can choose as you like.

when you pay for the pre-payment, we will arrange producing which about 7--15 days.

If you have any doubt, please contact with me, l will reply for you in time.

Похожие товары

Волоконный лазер 1.5kw 3kw 6kw для резки листового металла с конкурентоспособной ценой

Волоконно-лазерная резка с 1500 Вт 2000 3000

Станок для лазерной резки металла станок нержавеющей стали производственного завода

Машина для лазерной резки 3030 TruLaser Trumpf высокая точность и эффективность идеально подходит продвинутой металла

Профессиональный Co2 лазерный уплотнитель гравировальная машина 4030/мини гравер резак 50 Вт

Лазерная гравировальная машина 4040

2021 новый дизайн 1325 1630 Co2 широкоформатная кровать для лазерной резки

Новые поступления

Новинки товаров от производителей по оптовым ценам