Машина для производства фруктовых соков

- Категория: >>>

- Поставщик: Henan Zhong Yi Long Machinery Equipment Co. Ltd.

Сохранить в закладки 1600805486171:

Описание и отзывы

Характеристики

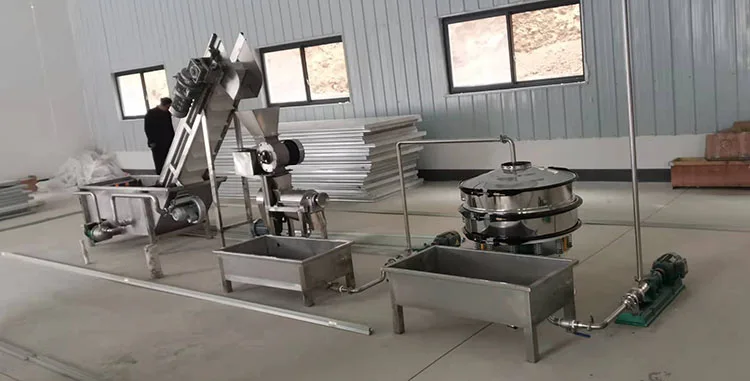

Fresh Juice Filling Machine Production Line

This filling machine production line is consisted with RO water treatment system,fruit cleaning machine, juice extractor, vibrating filter, steam kettle, sterilization machine,bottle washing machine, filling machine, capping machine, automatic labeling machine.

This filling machine production line is suitable for fresh juice (apple, pineapple,orange, mango) making and filling, tomato paste or ketchup making and filling, and so on.

All machines in the production line can be customized according to the customer's requirements.

RO Water Treatment System

Water treatment is equipped for pure water, mineral water, and water used in beverage drink. It contains RO, natrium filter, ultra filter, activated carbon filter, ozone processor etc. The purified water is used to clean tin cans and fill.

Fresh Juice Cleaning Machine And Juice Extractor

1, Use the bubble cleaner to clean fruits and vegetables.

2, Through the conveyor belt, into the juicer extractor.

3, Then through the vibrating machine to filter.Make the juice more delicate.

Vacuum degassing equipment and homogenizer

Vacuum degassing equipment adopts vacuum system to remove the smelly and oxygen in the juice.This equipment is composed of degassing part, condensing part, vacuum pump, etc; It is widely used in juice industry.

The high pressure homogenization machine is the special equipment for the homogeneous refinement and high pressure transportation of liquid materials.

Jacketed Kettle

Jacketed pot is also known as steam pot, cooking pot, jacketed steam pot.

It usually consists of a pot body and a supporting foot. The pot body is a double-layer structure consisting of an inner and outer spherical pot body. The middle inter layer is heated by steam.

It usually consists of a pot body and a supporting foot. The pot body is a double-layer structure consisting of an inner and outer spherical pot body. The middle inter layer is heated by steam.

After concentration, the juice is blended by jacketed kettle.

Ultra high temperature sterilization machine

Ultra high temperature instantaneous sterilization machine temperature at 115°C-135°C.The sterilization time is 3-5 seconds.It’s composed of centrifugal pump sterilization machine hot and cold in the heat exchange device for preheating, after high temperature bucket full of high pressure, the material being rapidly heated to and after the sterilization temperature keep about 3 seconds,

the microbes and enzymes were quickly kill. Material after the heat barrel by heat exchange with cold material for cooling, average temperature below 65 °C.

the microbes and enzymes were quickly kill. Material after the heat barrel by heat exchange with cold material for cooling, average temperature below 65 °C.

Semi automatic Bottle Washing Machine

This bottle washing machine is mainly used for cleaning new glass bottles or old cleaned bottles and polyester bottles before filling.There are 32 washing heads. It has the advantages of labor-saving, high production efficiency, low water consumption, simple structure and convenient maintenance.It is widely used in wineries, beverage factories, brewing factories, pharmaceutical factories and other packaging lines.

Filling Machine

All of the filling machine can be customized according customer's requirements. Semi automatic or fully automatic filling machine.

Automatic Labeling Machine

There is different labeling machines according to your bottles and sticker position ,1 such as round bottle labeling machine, square bottles single side labeling machine , two sides labeling machine , top and sides labeling machine ,feeding and capping machine and so on.

There is different labeling machines according to your bottles and sticker position ,1 such as round bottle labeling machine, square bottles single side labeling machine , two sides labeling machine , top and sides labeling machine ,feeding and capping machine and so on.

Automatic printing machine

You can choose the hot ribbon printer , inkjet print ,laser printer and so on

You can choose the hot ribbon printer , inkjet print ,laser printer and so on

All of our filling lines have CE certifications , 1 year warranty ,free accessories ,online operation guide

If you are interested in this Filling lines,please contact us.

If you are interested in this Filling lines,please contact us.

Related Products

About us

FAQ

Q1: Where is your factory? How can I visit your factory?

A: Our factory is located in Henan Province. If you have a travel plan, we warmly welcome you to visit our factory.

Q2: Can you send me a video to show me how the machine works?

A: Of course, we made videos of each machine.

Q3: How do I know your machine is designed for my product?

A: You can send us your product samples, and we will test them on the machine.

Q4: How do I pay for my order?

Answer: Usually we accept L/C, D/A, D/P, T/T, Western Union, Money Gram and cash payment .

Q5: Do you have a Ce certificate?

A: For each model of machine, it has CE certification

Q2: Can you send me a video to show me how the machine works?

A: Of course, we made videos of each machine.

Q3: How do I know your machine is designed for my product?

A: You can send us your product samples, and we will test them on the machine.

Q4: How do I pay for my order?

Answer: Usually we accept L/C, D/A, D/P, T/T, Western Union, Money Gram and cash payment .

Q5: Do you have a Ce certificate?

A: For each model of machine, it has CE certification

Похожие товары

Бар производитель равноценный разъем 38X38X2.2mm стержневой клапан 250X250X24mm 904L 25/2 30/2 40/2 угловой железо

600,00 $ - 650,00 $

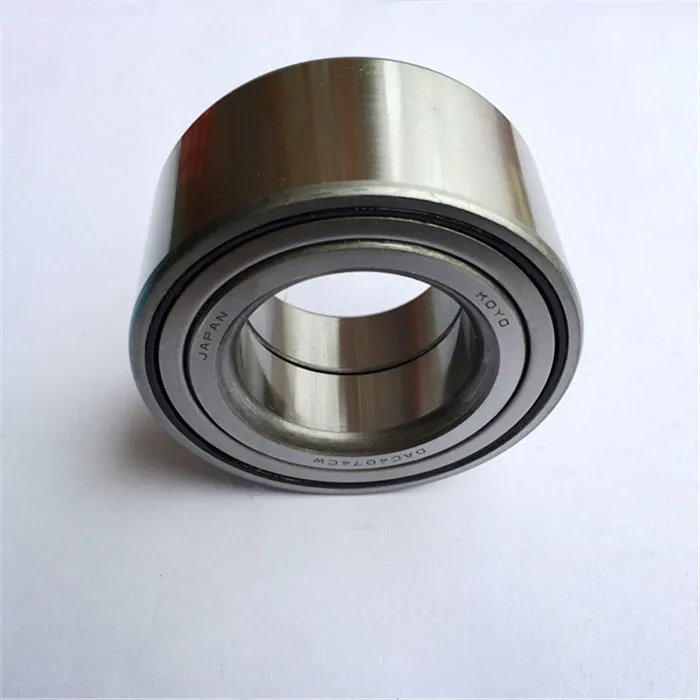

Поставка Автомобильного подшипника KOYO, колесный подшипник 356535, подшипник

10 шт./компл. OTG 5pin F/M мини-переходник адаптер конвертер USB «штырь-гнездо» Micro 2 0 гаджеты

0,05 $ - 2,00 $

Набор из 155 деревянных блоков с узором Геометрическая головоломка-манипулятор для детского сада классические развивающие игрушки

1,79 $ - 2,20 $

Акриловые Кольца из смолы, разноцветные кольца со стразами, ювелирные изделия, пластиковая смола, квадратный драгоценный камень, составное массивное кольцо

Японские Аниме игрушки-убийцы демонов Kimetsu no Yaiba, хлопковые плюшевые куклы, 20 см

2,30 $ - 2,85 $

К фильтру HYDAC (100% новый и оригинальный к фильтру HYDAC (давления датчик давления EDS1791-P-100-000-DC24V

50,00 $ - 130,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Кокосовая стружка мягкая и сладкая на вкус без глютена запеченная Ароматизированная упаковка для приготовления пищи кондитерских

Медицинский одноразовый стерильный катетер

Эффективные акустические панели эффективные звукоизоляционные материалы для качественной

65% полиэстер/35% хлопок саржа TC камуфляжная ткань 220gsm с водонепроницаемым принтом

1,48-1,61 $

Органическое жидкое мыло для мытья рук оптом

0,66-1,46 $

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $