Внутреннее Внешнее украшение PE PVDF durabond пластиковое acm dipbond зеркало 3 мм мраморная фасадная каменная acp алюминиевая композитная панель

- Категория: >>>

- Поставщик: Guangzhou Xinghe Decorative Material Co. Ltd.

Сохранить в закладки 1600810549932:

Описание и отзывы

Характеристики

Product Paramenters

PVDF COATING Aluminum composite panel

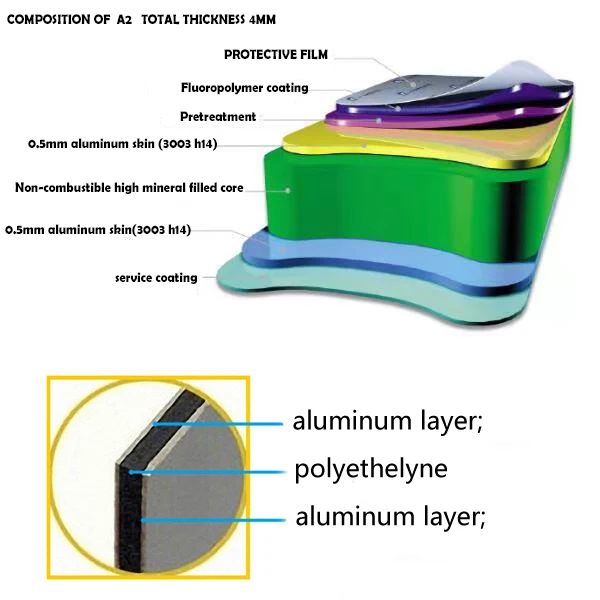

The aluminum-plastic composite panel is composed of multiple layers of materials. The upper and lower layers are high-purity aluminum alloy plates, and the middle layer is non-toxic low-density PE core board. The front side of the board is also coated with a protective film. For outdoor, the front of the aluminum-plastic plate is coated with PVDF, while for indoor, the front can be coated with non-fluorocarbon resin.

Products Description

Front side | Aluminum Alloy(3003) coated with Fluorin carbon resin (PVDF) or Polyester resin (PE) roasting painting |

Core | Non-toxic polyethylene or Plastic fireproof materials(B1/A2) |

Back side | Aluminium alloy sheet coated with polyester resin painting |

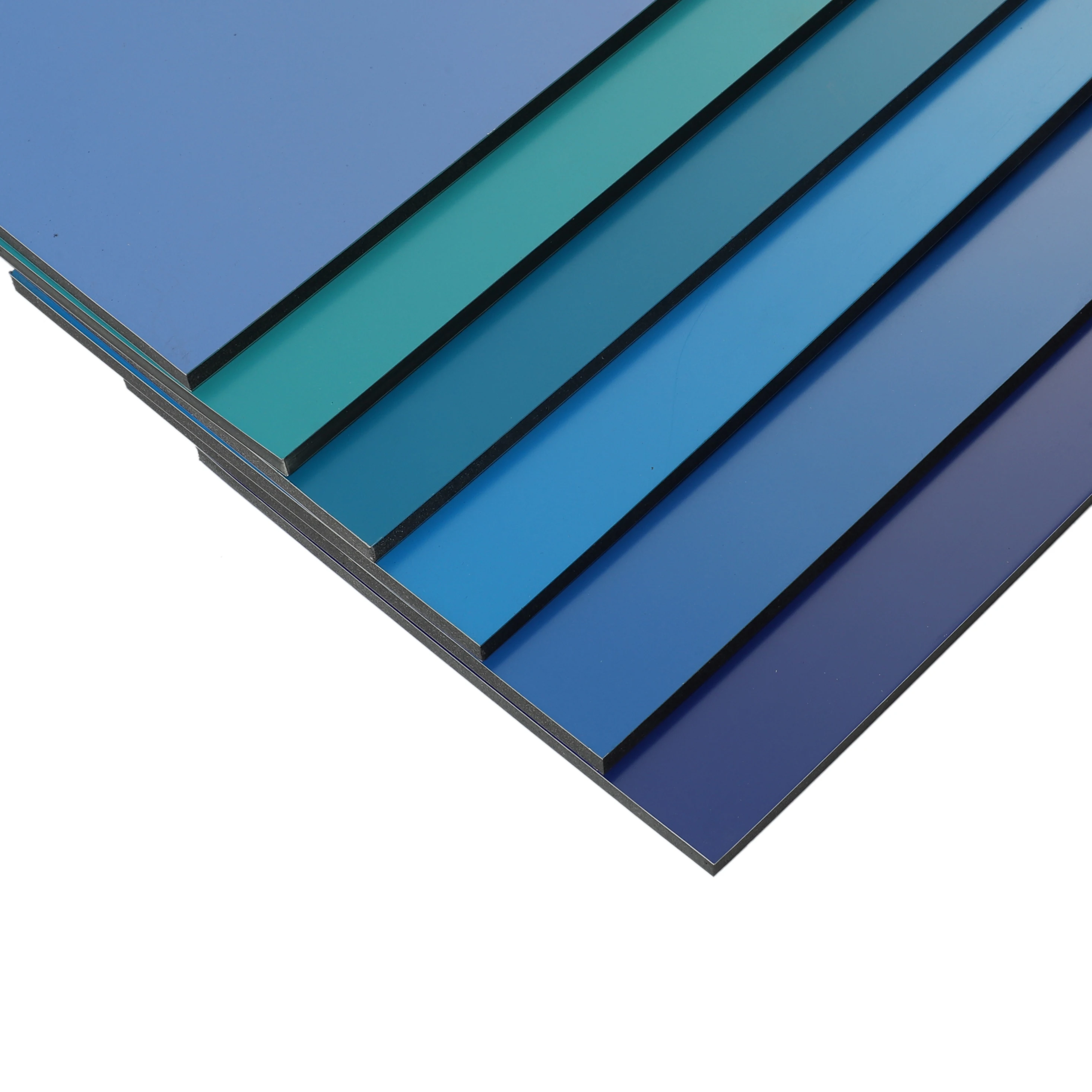

Panel Thickness | 2mm,3mm,4mm,5mm,6mm are available |

Alu thickness | 0.5mm,0.4mm,0.3mm,0.21mm,0.18mm,0.15mm, 0.12mm,0.1mm,0.06mm |

Width | 1220mm(regular),1250mm,1300mm,1500mm, 1550mm,1570mm,1575mm(Maximum) |

Length | 2440mm(regular),and or by customer’s offers,5800mm(Maximum) |

Standard size | 1220(Width)x2440(Length)x3mm(Thickness); 1250(Width)x2440(Length)x4mm(Thickness); |

Surface Finish | MIRROR ,MARBLE IMITATION,WOOD IMITATION,BRUSH,PVC FILM,PP FILM,PEARL SERIES,GLOSSY SURFACE,MATT SURFACE |

Core material | ( Normal non toxic polyethylene, one side unbroken polyethylene, two side unbroken polyethylene, virgin LDPE, ) B1 non-combustible mineral filled core,A2 non-combustible mineral filled core |

Coating | PE COATING,PVDF COATING,FEVE COATING,ANODIZED COATING |

Standard | According to China National Standard GB/t 17748-2016 |

Technical data of PVDF aluminum composite panel | ||||||||

Thickness of coating | PVDF paint ≧25 um | 26um to 28um | ||||||

Coating Flexibility (T-bend) | PVDF paint≦2T | 2T | ||||||

Coating Adhesion | ≧1 grade for 10*10mm2 gridding test | 1 grade | ||||||

Pencil Hardness | ≧HB | HB | ||||||

Resist Solvent | No change for 200 times (MEK) | No change | ||||||

Chemical Resistance | 5%HCL or 5%NAOH-No change for 24hours | No change | ||||||

Boiling Water Resistance | coating no tear off for 2 hours boiling | no tear off | ||||||

Color difference | △E≦2.0(follow color sample) | 0.5 | ||||||

Panel Peeling Strength | 7 N/mm for 4mm panel with 0.5mm aluminium. skin | 7N/mm | ||||||

Impact Test for paint | 50Kg.cm impact--paint no split for panel | no split | ||||||

Abrasion Resistance(L/Mil) | ASTM D968 | 44 | ||||||

Chemical Resistance | ASTM D1308 | Appearance: No change | ||||||

Film Adhesion | ASTM D3359(Note 1) | 5B | ||||||

Detergent Resistance(3%) | ASTM D2248 | Appearance: No change | ||||||

Stripping Strength(kgf/inch) | ASTM D903 | 18.5 | ||||||

Humidity Resistance (3000hrs,100%RH,100°F) | ASTM D2247 | Appearance: No change | ||||||

Salt Spray Resistance (3000hrs,5% salt) | ASTM B117 | Appearance: No change | ||||||

Aluminum coils

Coils transfer

PE Extrusion

poly film lamination

composite

Trim and Cutting

Products Test

width checking

length checking

diagonal (line) checking

Thickness Checking

Coating Thickness Measurement

color deviration deltal E TESTING

Boiling Water resistance Test

180 degree adhesive Peeling off strength test

pencil hardness Testing

Impact Resistance Test

Salt Spray Resistance Test

solvent Resistance Test

Flexural Elasticity Strength tests

T Turns Testing

uv aging Test

Production & Fabrication

Aluminum composite panel Applications

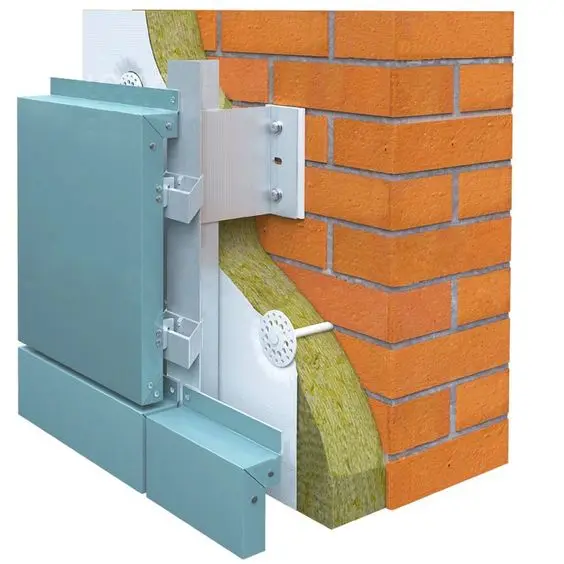

1.Constructional exterior curtain walls;

2.Decorative renovation for store-added old buildings;

3.Indoors decoration for interior walls, ceilings, bathrooms, kitchens and balconies; 4.Gallaies,exhibition,saloons,stores,offices,banks,hotels,restaurants and apartments; 5.Advertisement board, display platforms and signboards;

6.Raw materials in industrial purpose;

7.Materials used for vehicle and boat.

2.Decorative renovation for store-added old buildings;

3.Indoors decoration for interior walls, ceilings, bathrooms, kitchens and balconies; 4.Gallaies,exhibition,saloons,stores,offices,banks,hotels,restaurants and apartments; 5.Advertisement board, display platforms and signboards;

6.Raw materials in industrial purpose;

7.Materials used for vehicle and boat.

Hot sale

Certifications

Package and shipment

Thailand 19‘s Architecture

Canton Trade Fair

Philippines WorldBex

WHY CHOOSE US?

20+ Years History | Professional in manufacturing, marketing and service for 20+years. |

Production capacity | 4 aluminum coils coating lines,10 production lines, 60,000meter square/day. Your order leadtime is warranted |

Selected material suppliers | PPG/akzonobel/Kynar 500/ CHALCO, fast Delivery of Materials . |

Flexible MOQ | Small order will be accepted depending on stocking color and thickness of Aluminum coils. |

Excellent color Customization | Color picture, RAL/pantone Etc color code, sample provided to us for color customization |

More option for width customization | Normal 1220,1250,1500,1570,1575mm, but we also provide special width customization : 610mm,900mm,1100mm Etc |

OEM available | Just offer your design information, we will design your LOGO on your protective film. |

Superior location | Guangzhou nansha, close to Baiyun airport and Canton Fair |

Strict Quality Controlling | ISO9001:2018, PPG, SGS, KYNAR500 |

Free sample | Free sample offered, 7 days delivered to you. |

COMPANY PROFILE

Guangzhou Xinghe Decorative Material Co., Ltd is one of the biggest decorative building materials enterprises in China. It is specialized in producing decorative building materials such as Fire-rated B1 Aluminum Composite Panel,Fire-rated A2 Aluminum Composite Panel.PE/PVDF/FEVE Aluminum Composite Panel.Film Coated Aluminum Composite Panel.Aluminum honeycomb panel Fire-rated A2.Aluminum solid panel Fire-rated A2.Aluminum ceiling system . Our company was founded in 1999. The factory covers area of 20,000 square meters, with nearly 100 people of various kinds of advanced management, design development and production staff. It has 12 advanced international technology production lines of aluminum composite panels, which can produce two-meter width aluminum composite panel curtain wall, with an annual production capacity of 15 million square meters ACP, and 5 million square meters of aluminum honeycomb panels. Xinghe production lines include the most complete varieties, designs and colors in the field.

FAQ

Q: How soon can I get a reply?

A: 1 hour in daytime. 6-8 hours in sleep time.

Q:Can I get a sample?

A: Yes, sample is free, only freight collected. about 30-60dollars for 1kg weight.

Q:Can my order be produced by my brand?

A: Yes, we could produce all goods with your brand or LOGO.

Q: What’s your delivery time?

A: Normally 20days after deposit. if have stock raw materials, 10 days enough.

Q: Is there a minimum order requirement?

A: MOQ is basis on Alu thickness; 0.3mm Alu MOQ 600m2

Q:Accessories service?

A: Yes, We supply installation accessories for aluminum composite panel. such as aluminum extrusions, sealant etc.

Q:Will you match competitors' prices?

A: As details request, then can decide. Each company always have been in different advantage.

Q:Why I can trust you and make order from you?

A: MEGABOND has 22 years experience in Aluminum composite panel manufacturing, and as a member of the Alibaba’s Golden Trusted Supplier Also you could contact me to look comments from our old clients.

Q: How soon can I get a reply?

A: 1 hour in daytime. 6-8 hours in sleep time.

Q:Can I get a sample?

A: Yes, sample is free, only freight collected. about 30-60dollars for 1kg weight.

Q:Can my order be produced by my brand?

A: Yes, we could produce all goods with your brand or LOGO.

Q: What’s your delivery time?

A: Normally 20days after deposit. if have stock raw materials, 10 days enough.

Q: Is there a minimum order requirement?

A: MOQ is basis on Alu thickness; 0.3mm Alu MOQ 600m2

Q:Accessories service?

A: Yes, We supply installation accessories for aluminum composite panel. such as aluminum extrusions, sealant etc.

Q:Will you match competitors' prices?

A: As details request, then can decide. Each company always have been in different advantage.

Q:Why I can trust you and make order from you?

A: MEGABOND has 22 years experience in Aluminum composite panel manufacturing, and as a member of the Alibaba’s Golden Trusted Supplier Also you could contact me to look comments from our old clients.

CONTACT US

GUANGZHOU XINGHE DECORATIVE MATERIAL CO,.LTD

Address: No 8 maxing street make vallage, Dongchong Town, Nansha district Guangzhou City. PRC. Potsal code: 511475

Whatsapp/WechatWhatsapp/Wechat/Skype/Fcebook/Ins: +86-158-0002-4882

Email: xh003@gz-xinghe.com.cn

www.megabondacm.com

Address: No 8 maxing street make vallage, Dongchong Town, Nansha district Guangzhou City. PRC. Potsal code: 511475

Whatsapp/WechatWhatsapp/Wechat/Skype/Fcebook/Ins: +86-158-0002-4882

Email: xh003@gz-xinghe.com.cn

www.megabondacm.com

Похожие товары

Сверхмощная батарея 1,5 в R03P AAA, батарея с Заводской ценой и высоким качеством

CT9 Biometric Qr Generator Access Control Wristband Nfc Light Up Automate The Enter Of Gym With Camera

Экспортный заводской клей для этикеток, не сухой клей, чувствительный к жидкому давлению клей, используемый для наклеивания этикеток и производства БОПП PSA

0,88 $ - 1,00 $

Профессиональный монитор Hmi v606ec20с сертификатом CE

333,00 $

2021 горячая Распродажа Q12 Смарт-часы 2G для детей анти-потеря SOS звонок GSM LBS определение местоположения Детские Смарт-часы Q12 игра Смарт-часы

3,37 $ - 6,35 $

Универсальная Светодиодная лампа для автомобильных фар h11 60 Вт 8400 лм csp y19 led чипы h1 h3 h7 h8 h9 h4 h16 ip68 Водонепроницаемые светодиодные лампы

25,00 $ - 32,00 $

Нож-гриб из нержавеющей стали, карманный складной резец с ручкой из розового дерева, нож электрика, инструменты для выживания в кемпинге

1,45 $ - 1,65 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $