U образный силиконовый нагреватель SiC керамический нагревательный элемент Электрический стержень 1500C GC типа высокой

- Категория: Heating Equipment >>>

- Поставщик: Shandong Robert New Material Co. Ltd.

Сохранить в закладки 1600813140215:

Описание и отзывы

Характеристики

1. High purity MoSi2 heating element, for various electric furnaces , especially dedicate for high purity furnace.

2. Fast ramping.

3. Max working temperature 1850 ℃.

4. Can be used continuously or intermittently.

5. New and old elements can be connected in series.

6. High power concentration may be applied.

7. Long life combined with ease of replacing failed elements contributes to a high degree of

2. Fast ramping.

3. Max working temperature 1850 ℃.

4. Can be used continuously or intermittently.

5. New and old elements can be connected in series.

6. High power concentration may be applied.

7. Long life combined with ease of replacing failed elements contributes to a high degree of

utilization of the furnace and low maintenance costs.

Outer Diameter(mm) | Hot Zone(mm) | Cold Zone(mm) | Overall Length(mm) | Range of Resistance |

8 | 100-300 | 60-200 | 240-700 | 2.1-8.6 |

12 | 100-400 | 100-350 | 300-1100 | 0.8-5.8 |

14 | 100-500 | 150-350 | 400-1200 | 0.7-5.6 |

16 | 200-600 | 200-350 | 600-1300 | 0.7-4.4 |

18 | 200-800 | 200-400 | 600-1600 | 0.7-5.8 |

20 | 200-800 | 250-600 | 700-2000 | 0.6-6.0 |

25 | 200-1200 | 250-700 | 700-2600 | 0.4-5.0 |

30 | 300-2000 | 250-800 | 800-3600 | 0.4-4.0 |

35 | 400-2000 | 250-800 | 900-3600 | 0.5-3.6 |

40 | 500-2700 | 250-800 | 1000-4300 | 0.5-3.4 |

45 | 500-3000 | 250-750 | 1000-4500 | 0.3-3.0 |

54 | 600-2500 | 300-750 | 1200-4000 | 0.3-3.0 |

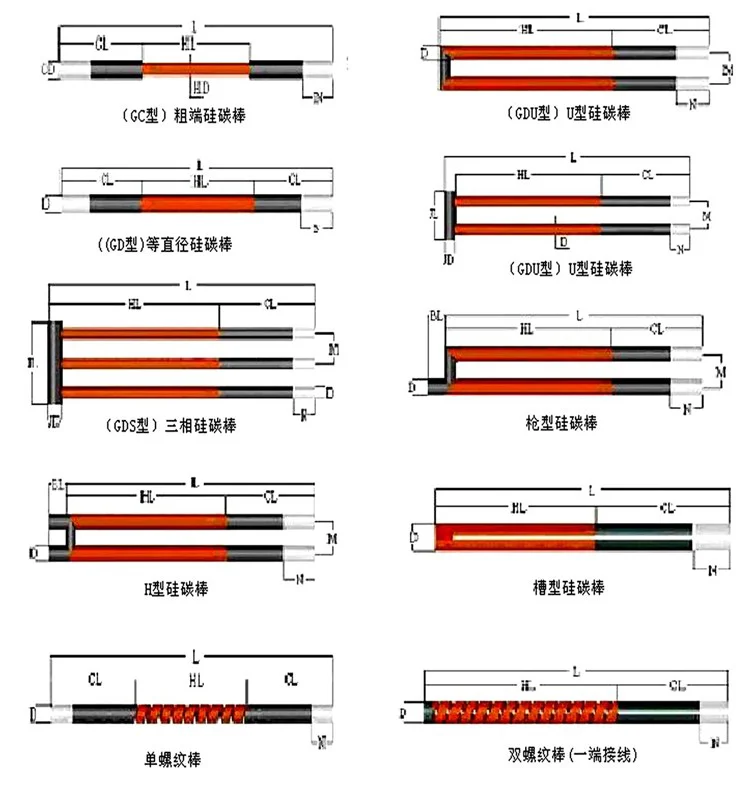

1. Thick and short silicon carbide rods (GC type) are often used in old-fashioned heat treatment furnaces, experimental furnaces, tunnel furnaces, etc.

2. Equal diameter silicon carbide rod (GD type) is a substitute for thick end silicon carbide rod

It can be used as heating element for push plate furnace, mesh belt furnace, trolley furnace and box furnace.

3. Mountain-shaped silicon carbon rod (GDS type) is mainly used in float glass tin bath, optical glass melting, glass deep processing, controlled atmosphere electric furnace, etc.

4. U-shaped silicon carbide rod (GDC type): used in furnaces requiring single-ended wiring, commonly used in push-plate furnaces, trolley furnaces, box furnaces and other periodic electric furnaces.

5. Door type silicon carbide rod (GDC type): suitable for heating at the bottom or both sides of large box furnaces and trolley furnaces

6. H-type silicon carbide rod (GDH type): It is often used in the heating and heat preservation of the feeding channel and the material basin in the glass industry.

7. Gun-shaped silicon carbide rod: suitable for the material basin for processing glass products.

8. Slotted silicon carbide rod: used for heating and heat preservation of molten aluminum and zinc.

9. Special-shaped silicon carbide rods: mainly used in crucible aluminum melting furnaces

2. Equal diameter silicon carbide rod (GD type) is a substitute for thick end silicon carbide rod

It can be used as heating element for push plate furnace, mesh belt furnace, trolley furnace and box furnace.

3. Mountain-shaped silicon carbon rod (GDS type) is mainly used in float glass tin bath, optical glass melting, glass deep processing, controlled atmosphere electric furnace, etc.

4. U-shaped silicon carbide rod (GDC type): used in furnaces requiring single-ended wiring, commonly used in push-plate furnaces, trolley furnaces, box furnaces and other periodic electric furnaces.

5. Door type silicon carbide rod (GDC type): suitable for heating at the bottom or both sides of large box furnaces and trolley furnaces

6. H-type silicon carbide rod (GDH type): It is often used in the heating and heat preservation of the feeding channel and the material basin in the glass industry.

7. Gun-shaped silicon carbide rod: suitable for the material basin for processing glass products.

8. Slotted silicon carbide rod: used for heating and heat preservation of molten aluminum and zinc.

9. Special-shaped silicon carbide rods: mainly used in crucible aluminum melting furnaces

Похожие товары

Настраиваемая силиконовая индукционная нагревательная пластина AC DC с CE

Greenhouse Poultry Coop Electric Heaters Piglet House Chick Brooder Chicken Heater Breeding Equipment Heating Brooder

110,00 $ - 120,00 $

Промышленное электромагнитное нагревание удаляет корродированный винт Электромагнитная Индукционная катушка индукционный

139,14 $ - 171,74 $

EW-19B высокую точность контроля термоусадочные трубки пистолет для проводов термоусаживаемые трубчатого

600,00 $ - 650,00 $

Керамический изолированный нагреватель каналов 25 1/2 дюйма в длину для нагрева пресс-форм и

102 684 3*400 в 3*5500 керамический нагреватель для горячего воздуха 10000S 17K Используется машины изготовления бумажных

60,00 $ - 88,00 $

Промышленные нагреватели с принудительным газом 10 кВт портативный уличный газовый обогреватель для теплиц сжиженного углеводородного газа курицы

33,88 $ - 58,88 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

OrionStars онлайн-машина для рыбалки и свинга высокоприбыльная монетная игра США оптовая продажа агент с высокой прибылью Разыскивается

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $