1500l 15hl автоматическое полированное использованное полное 4 сосудное пивоваренное оборудование для продажи

- Категория: Food & Beverage Machinery >>>

- Поставщик: Shandong Tiantai Beer Equipment Co. Ltd.

Сохранить в закладки 1600828551438:

Описание и отзывы

Характеристики

1500l 15hl Automatic polished used complete 4-vessel beer brewing equipment for sale

1).Product description

The 4-vessel beer equipment is usually used for industrial brewery System and commercial brewery system. We offer the Industrial brewery with the productivity of 500L (5hl) to 15000L (150hl) per brew. Usually the system is large.

At this point, mashing, lautering, boiling and whirlpool are separated and performed in fours tanks, and the agitator is installed in the mash tun. The lauter tun is designed to be flat bottom and has wort collect cycle at the bottom. The whirlpool tun is designed to conical bottom with dam or inclined bottom with 2 degree slop.

Heating includes Steam Heating, electric and direct fire. From heating efficiency, steam heating is best since it can heat mash/wort evenly and vigorously, as well as no scorch. But steam heating will request steam generator and pipeline as auxiliary machine, which increases budget to some degree. We can also provide electric and direct fire if you need it.

2) .Specifications

Malt Milling Unit | Malt Miller | Rollers clearance adjustable for various malt particle | 1set | ||

Flexible Auger | Flexible food grade PVC pipe, abrasion resistance | 1set | |||

Brewhouse | Mash Tun | Agitator with positive inversion control | 1set | ||

Lauter Tun | Equally distributed Circular mouth wort outlet with extended collection ring at bottom | 1set | |||

Back pressure flushing device under false bottom with nozzels | |||||

Sparging spray ring on top Easyclean and detachable | |||||

Kettle Tun | Steam condensor with spray nozzle and valves

| 1set | |||

Whirlpool Tun | Tangential whirlpool inlet with reducing port | 1set | |||

conical bottom with dam | |||||

Hot Water Tank | Floating ball level sensor for stopping heating | 1set | |||

Wort Balance Column | Avoiding negative pressure under false bottom and wort flow speed monitor | 1set

| |||

Heat Exchanger | Two stages for city water and glycol water gives prompt wort cooling within 30-40 minutes | ||||

Fermentation Unit | Fermentation Tank/Unitank | CO2 blow-off arm with butterfly valve | 4sets | ||

Dry hopping port 4'' with solid end cap | |||||

Horizontal mounted rotating racking arm and port in cone | |||||

Bright Beer Tank | Carbonation port with CO2 dissolved stone | 1set | |||

Glycol Cooling Unit | Glycol Water Tank | Insulation: PU, TH=80mm | 1set | ||

Cold Water Tank | Cold water supply for wort cooling |

| |||

Glycol Water Chiller | Cooling: Circulated 35% Glycol liquid -5℃ | 2sets | |||

Intelligent anti-freezing protection | |||||

Electric Control Unit | Brewhouse and Fermentation Control Cabinet | PLC control with touch screen for special request | 1set | ||

3) .Key Features

1. Automatic control: It achieves full-automatic heating and cooling. What you only need to do is to open/close butterfly valve etc.If you need to automate the configuration, you can choose PLC automatic control, labour saving based on penumatic valve.

2. Welding and Polishing: We abandoned the argon gas cylinder but adopt The Central System of Argon to make sure the TIG welding with pure argon gas shield. And we use large-scale polishing equipment to polish the inside of the tanks all over the wall to make sure there is no dead corner. You need not worry about there will be some bacteria remained after cleaning.

3. Portable CIP cart: It is one of our features.It allows you to clean your equipment anytime and anywhere. What's more, it’s environmental friendliness shows from the heat energy recycle, which can save energy and protect the environment.

4).Other Choices

Our equipment has different combination as below,you can choose each one according to your budget and hobby.

*Two Vessel: Mas/Lauter Tun+Kettle/Whirlpool Tun+HLT

*Three Vessel: Mash Tun+Lauter Tun+Kettle/Whirlpool Tun+HLT

Two Vessel Brewhouse can maximize the use of space through higher specification designed.

Three Vessel Brewhouse is available with several options to help deliver brewing efficiency and overall flexibility.

Four Vessel Brewhouse is the best way to maximize production and cost efficiency.

5).Service provided

1. We can help clients with layout design and provide customization according to different needs.

2. We provide free pre-sales consultation service. If you have any questions, we will reply you within 12 hours.

3. If no experience,we can provide 3D and 4D drawings and installed instruction at site.

4. We have five years warranty for tanks.

5. The time you receive the product:Within 60-90 days after confirmation of the initial payment. In the production process, we will follow up the production of the equipment for you at any time.

6).Why choose us?

Tiantai is a professional and experienced company of making brew equipment.We accumulated many customers from 80 countries and received good reputation.We have not only advanced technology,but also comprehensive service.Whatever you have experience or not,if you choose the turnkey operation,we will give you a satisfactory result.

Похожие товары

Поворотный электрический паровой чайник из нержавеющей стали с подогревом 600

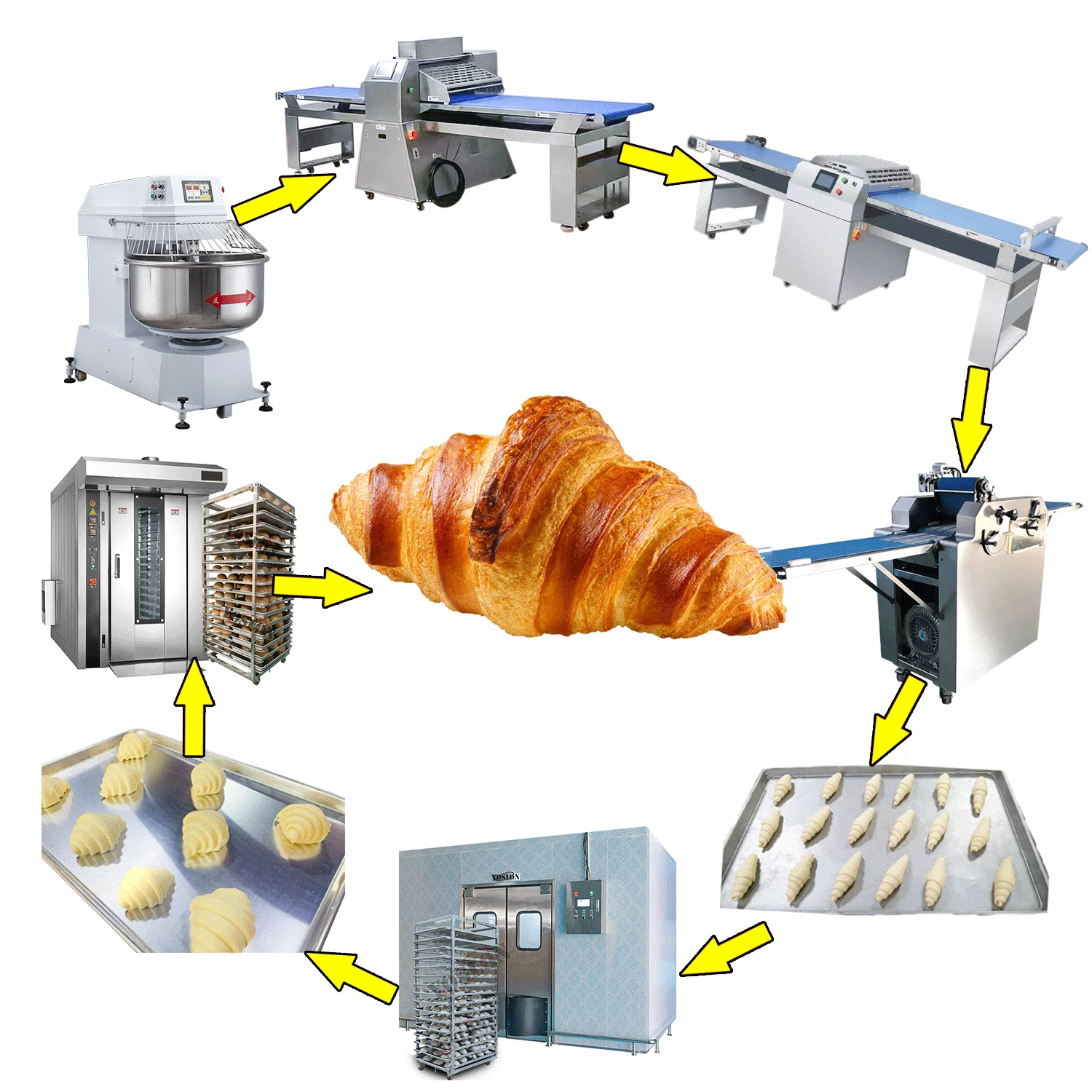

Простая в эксплуатации производственная линия Круассанов, полностью автоматическая машина для производства Круассанов

Электрическая столешница для приготовления хлопчатобумажных конфет миниатюрная машина детей домашний подарок на день рождения семейный праздник

GQ-25CTB завод прямые продажи коммерческого мягкой машина мороженого 3 вкусов агрегат для производства мягкого Чехол класса

Одобренный CE шейкер для чая с пузырями встряхивающая машина Миксер молочного жемчугом

Заводская индивидуальная машина для стерилизации тунца высококачественные банки пищевых продуктов небольшая

Машина для производства кормов животных полная линия

Новые поступления

Новинки товаров от производителей по оптовым ценам