2 дюйма из нержавеющей стали Поплавковый шаровой клапан резервуар для воды

- Категория: >>>

- Поставщик: Wenzhou Compass Machinery Co. Ltd.

Сохранить в закладки 1600829166288:

Описание и отзывы

Характеристики

Product Description

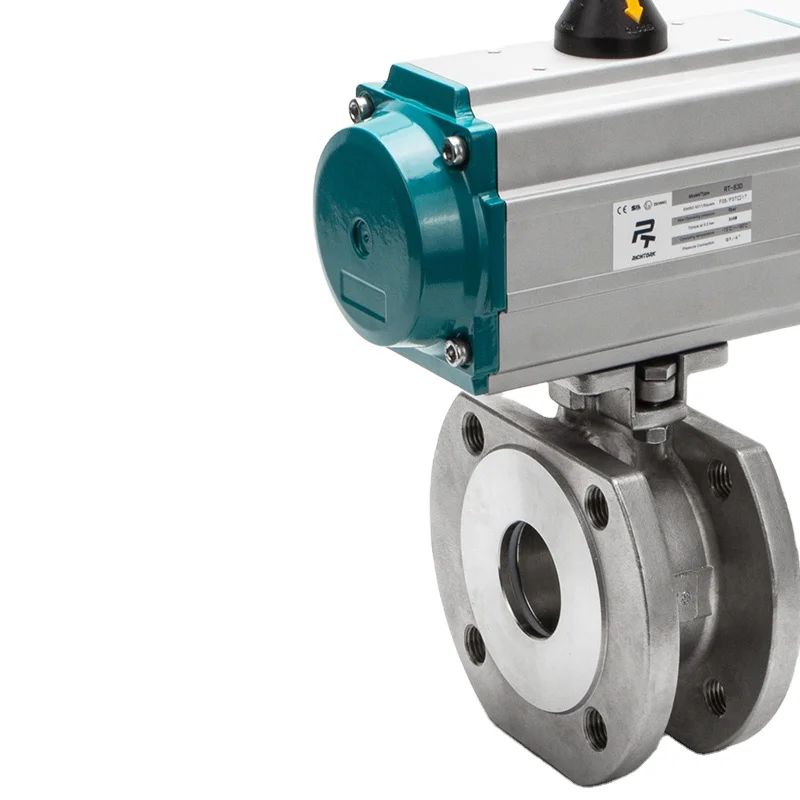

2 inch Stainless steel float ball valve stainless steel water tank float ball valve

Float ball valve is a valve composed of curved arms and floating balls, which can be used to automatically control the liquid level of a water tower or pool.

Float ball valve is a ball without a supporting shaft, which is held in a "floating" state by two valve seats. It is mainly used for cutting, distributing, and changing the direction of medium flow in pipelines. Floating ball valves mainly have structural features such as valve seat sealing design, reliable reverse sealing valve stem, fire and static electricity prevention function, automatic pressure relief and locking device.

Float ball valve is a ball without a supporting shaft, which is held in a "floating" state by two valve seats. It is mainly used for cutting, distributing, and changing the direction of medium flow in pipelines. Floating ball valves mainly have structural features such as valve seat sealing design, reliable reverse sealing valve stem, fire and static electricity prevention function, automatic pressure relief and locking device.

Specification

Commodity | Float Ball Valve | |||||||

Component | Valve Body, Valve Cap, Seal, Plug, Rod, Ball, Nut | |||||||

Type of Float Ball Valve | Stainless Steel Float Ball Valve | |||||||

Small Hole Float Ball Valve | ||||||||

Plastic Float Ball Valve | ||||||||

Design Type | Levered Type, Straight Through | |||||||

Material Contact Parts | SS304(1.4301),SS316 (1.4401),Brass,SS201 | Provided with material inspection report | ||||||

Material Non-contact Parts | SS304(1.4301),SS201 | |||||||

Sealing Material | NBR,EPDM,Silicone,FKM. All material comply with FDA21CFR117.2600 | |||||||

Connection Size | DN15,DN20,DN25,DN32,DN40,DN50,DN65,DN80,DN100 | |||||||

Ball Size | 95mm,135mm,150mm,225mm,250mm,280mm,300mm | |||||||

Connection | Screw Thread, Tri-clamp,Flange | |||||||

Max. Pressure | 16bar (232psi) | |||||||

Workingl Pressure | 6bar (87psi) | |||||||

Design Temperature | -4 ~ +392°F (-20℃~+200 ℃) | |||||||

Rotation Angle | 360° | |||||||

Drive Mode | Hydraulic Control | |||||||

Flow Direction | Single One-way | |||||||

Media | Water | |||||||

Customized Support | OEM,OED | |||||||

Size | Valve Body Length | Rod Length | Thread Length | Float Ball Length | Net Weight | Gross Weight | Technical Parameter | ||

DN15 | G1/2" | 65mm | 150mm | 13mm | 100mm | 260g | 330g | -4 ~ +392°F (-20℃~+200 ℃) 16bar (232psi) | |

DN15 | G1/2" | 47mm | 285mm | 17mm | 115mm | 260g | 330g | ||

DN15 | G1/2" | 70mm | 220mm | 14mm | 110mm | 285g | 355g | ||

DN20 | G3/4" | 65mm | 150mm | 13mm | 100mm | 285g | 350g | ||

DN20 | G3/4" | 54mm | 365mm | 19mm | 135mm | 285g | 350g | ||

DN25 | G1" | 89mm | 215mm | 19mm | 135mm | 560g | 670g | ||

DN32 | G1-1/4" | 89mm | 230mm | 22mm | 150mm | 660g | 750g | ||

DN40 | G1-1/2" | 110mm | 220mm | 27mm | 220mm | 1700g | 6kg | ||

DN50 | G2 | 120mm | 200mm | 30mm | 250mm | 2000g | 6kg | ||

DN65 | G2-1/2" | 150mm | 280mm | 31mm | 300mm | 3500g | 9kg | ||

DN80 | G3" | 170mm | 240mm | 34mm | 380mm | 5000g | 10kg | ||

DN100 | G4" | 195mm | 240mm | 40mm | 380mm | 7000g | 12kg | ||

S/N | Item | Material | ||

1 | Valve Body | SS304/SS316/SS201/Brass | ||

2 | Valve cap | SS304/SS316/SS201/Brass | ||

3 | Seal | NBR,EPDM,Silicone,FKM | ||

4 | Plug | SS304/SS316/SS201/Brass | ||

5 | Stem | SS304/SS316/SS201/Brass | ||

6 | Ball | SS304/SS316/SS201/Brass | ||

7 | Nuts | SS304/SS316/SS201/Brass | ||

Working principle

The float always needs to float on the water, and when the water rises, the float also rises. When the float rises, it drives the connecting rod to also rise. The connecting rod is connected to the valve at the other end, and when it rises to a certain position, the connecting rod supports a rubber piston pad to seal off the water source. When the water level drops, the float also drops, and the connecting rod drives the piston pad to open.

Float valves regulate the liquid supply by controlling the liquid level. A full liquid evaporator requires the liquid level to maintain a certain height, and it is generally suitable to use a floating ball expansion valve. The working principle of a float valve is to control the opening or closing of a valve by lowering and raising the float ball in the float chamber under the action of the liquid level. The floating ball chamber is placed on one side of the full liquid evaporator, and the upper and lower parts are connected to the evaporator through a balance tube, so the liquid level height of the two is the same. When the liquid level in the evaporator drops, the liquid level in the floating ball chamber also drops, so the floating ball drops and relies on the lever to increase the valve opening and increase the liquid supply. vice versa.

Feature & Design

1. The valve is equipped with open and close position indicators;

2. Locking device;

3. Valve stem anti flying structure;

4. Anti static device;

5. Fire resistant structure;

6. Unique valve seat sealing structure;

7. no external leakage structure.

Advantages & Feature

1.Easy maintenance

2.Flexible and durable

3.High accuracy of liquid level control

4.The water level is not affected by water pressure and has the characteristics of tight opening and closing without water leakage

The float always needs to float on the water, and when the water rises, the float also rises. When the float rises, it drives the connecting rod to also rise. The connecting rod is connected to the valve at the other end, and when it rises to a certain position, the connecting rod supports a rubber piston pad to seal off the water source. When the water level drops, the float also drops, and the connecting rod drives the piston pad to open.

Float valves regulate the liquid supply by controlling the liquid level. A full liquid evaporator requires the liquid level to maintain a certain height, and it is generally suitable to use a floating ball expansion valve. The working principle of a float valve is to control the opening or closing of a valve by lowering and raising the float ball in the float chamber under the action of the liquid level. The floating ball chamber is placed on one side of the full liquid evaporator, and the upper and lower parts are connected to the evaporator through a balance tube, so the liquid level height of the two is the same. When the liquid level in the evaporator drops, the liquid level in the floating ball chamber also drops, so the floating ball drops and relies on the lever to increase the valve opening and increase the liquid supply. vice versa.

Feature & Design

1. The valve is equipped with open and close position indicators;

2. Locking device;

3. Valve stem anti flying structure;

4. Anti static device;

5. Fire resistant structure;

6. Unique valve seat sealing structure;

7. no external leakage structure.

Advantages & Feature

1.Easy maintenance

2.Flexible and durable

3.High accuracy of liquid level control

4.The water level is not affected by water pressure and has the characteristics of tight opening and closing without water leakage

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Contact Us

Application

Float ball valves are suitable for industries such as food, chemical, petroleum, natural gas, metallurgy, as well as natural gas long-distance pipelines containing hydrogen sulfide, impurities, and severe corrosion.

Company Profile

Founded in 2011, Compass Machinery as a global sanitary valves manufacturer,has grown to become one of leading valves manufacturers for high precision stainless steel sanitary valves, pipe fittings,pumps and tanks.

Totally 112nos of workers and the factory Covers 4035m2,our warehouse covers 1000m2. We have 29 sets of LG Mazak machines and other CNC machine from Japan ; Meanwhile,we have 2 sets of automatic machining unit.

To assure better quality, we have the full inspecting quality control

equipment: 1nos Ra roughness instrument, 3nos stainless steel spectrometer, numbers of roundness instrument, numbers of thickness instrument, numbers of radius instrument, 3 nos pressure testing center.

Compass Machinery is still developing and innovating new products to ensure that the products are more energy-efficient, efficient and competitive.

Totally 112nos of workers and the factory Covers 4035m2,our warehouse covers 1000m2. We have 29 sets of LG Mazak machines and other CNC machine from Japan ; Meanwhile,we have 2 sets of automatic machining unit.

To assure better quality, we have the full inspecting quality control

equipment: 1nos Ra roughness instrument, 3nos stainless steel spectrometer, numbers of roundness instrument, numbers of thickness instrument, numbers of radius instrument, 3 nos pressure testing center.

Compass Machinery is still developing and innovating new products to ensure that the products are more energy-efficient, efficient and competitive.

FAQ

Q1. Are you a trading company or factory?

We are a manufacturing factory.

Q2. What’s the payment terms?

For small testing orders,we accept Paypal,Western Union,T/T and credit Card.

For mass orders,we accept T/T and L/C.

Q3.How do you control the quality?

Quality control is very important to avoid material mixing and poor quality.We control the quality from beginning to the end.We only have 304 and 316L two different materials.100% inspection on raw material.During production,different materials in different place.After materials are finished,we choose 10% for inspection.If there is 0.1% problem in 10%,then no excuse to go ahead for inspecting 100% of the materials.

Q4.If there is any quality problem,how do you solve it?

We are proud that we never let one customer leave us.We are not 100% perfect,there is some quality problem.We try our best to provide the correct materials in the beginning,so we need less time for quality problem.If there is any quality problem,we take the responsibility.We believe what we are doing together,it will get back tomorrow.If we leave our responsibility,customer will leave us.If we always take our responsibility,we keep our customers with us.

Q5.How long is your delivery time?

For normal production in 7-10days.For bulk order in 15-25days.

Q6.Warranty

One year warranty for all of our stainless steel products.Gaskets are not included due to the different application for

customers.

Q7.How to order About Float Ball Valve?

We are a manufacturing factory.

Q2. What’s the payment terms?

For small testing orders,we accept Paypal,Western Union,T/T and credit Card.

For mass orders,we accept T/T and L/C.

Q3.How do you control the quality?

Quality control is very important to avoid material mixing and poor quality.We control the quality from beginning to the end.We only have 304 and 316L two different materials.100% inspection on raw material.During production,different materials in different place.After materials are finished,we choose 10% for inspection.If there is 0.1% problem in 10%,then no excuse to go ahead for inspecting 100% of the materials.

Q4.If there is any quality problem,how do you solve it?

We are proud that we never let one customer leave us.We are not 100% perfect,there is some quality problem.We try our best to provide the correct materials in the beginning,so we need less time for quality problem.If there is any quality problem,we take the responsibility.We believe what we are doing together,it will get back tomorrow.If we leave our responsibility,customer will leave us.If we always take our responsibility,we keep our customers with us.

Q5.How long is your delivery time?

For normal production in 7-10days.For bulk order in 15-25days.

Q6.Warranty

One year warranty for all of our stainless steel products.Gaskets are not included due to the different application for

customers.

Q7.How to order About Float Ball Valve?

1.What’s material ?

2.What’s size ?

3.What’s connection end ?

4.What’s type of float valve ?

2.What’s size ?

3.What’s connection end ?

4.What’s type of float valve ?

Похожие товары

Шаровой клапан из нержавеющей стали 3 pc с высокой платформой

JTAIV пневматический ультра-тонкий Пневматический шаровой клапан фланец высокой платформы 304 из нержавеющей стали фланцевый шаровой клапан

Китайский завод, цилиндрический шаровой клапан PN10 PN16 DN150, ультратонкий высокоплатформенный с пневматическим приводом

3-ходовой шаровой клапан высокой платформы, корпус и шарик из нержавеющей стали, 304 материал, высококачественный фланцевый трехходовой шаровой клапан

2 697,45 ₽ - 3 776,43 ₽

Ручной DN25 PVDF пластиковый фланцевый шаровой клапан с высокой платформой

DESO Заводская распродажа, профессиональный производитель, высококачественный клапан PPR

85,24 ₽ - 120,85 ₽

LJ-533 производитель пластиковый полипропиленовая форма железо высокого давления DN15 DN20 DN32 шаровой клапан с внутренним с внутренней резьбой

16,19 ₽ - 21,58 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $