Оборудование для переработки пластика очистки из полипропилена

- Категория: >>>

- Поставщик: Laizhou Yisu Machinery Co. Ltd.

Сохранить в закладки 1600833434530:

Описание и отзывы

Характеристики

Product Description

1. The whole production line is mainly designed for a large number of recycled PP/PE/PVC film, agricultural film, plastic film, packaging film, and a large number of convenient bags, vest bags, handbags, shopping bags, as well as cement bags, woven bags, snake skin bags, grain bags, fertilizer bags, jumbo bags, and other soft waste plastic broken cleaning and drying. Coordination with the follow-up process (granulation system) of the production line, which will make garbage film and dirty PE / PP film, PP woven bag is PE / PP film, PP woven bag particulate matter, used to produce new PE, PP film, etc.

2. the entire production line is fully automatic control, compact layout and high production efficiency.

3. Because it is an open combined equipment, different cleaning schemes, cleaning processes, recovery planning and site

planning can be designed according to the actual situation of users.

4. The equipment is widely used in recycling and processing enterprises which have a certain scale and pursue automation benefits, such as: recycled particles of large and medium-sized cement bags; recycling and granulating of PP and PE films; crushing and cleaning of waste plastic and plastic film materials in large paper mills and garbage dumps.

5. Capacity: 100KG/H-1000KG/H

6. Size of final product can be adjusted according to change crusher screen mesh.

2. the entire production line is fully automatic control, compact layout and high production efficiency.

3. Because it is an open combined equipment, different cleaning schemes, cleaning processes, recovery planning and site

planning can be designed according to the actual situation of users.

4. The equipment is widely used in recycling and processing enterprises which have a certain scale and pursue automation benefits, such as: recycled particles of large and medium-sized cement bags; recycling and granulating of PP and PE films; crushing and cleaning of waste plastic and plastic film materials in large paper mills and garbage dumps.

5. Capacity: 100KG/H-1000KG/H

6. Size of final product can be adjusted according to change crusher screen mesh.

Specification

Capacity(kg/h) | Power consumption (kw) | Water consumption (ton/h) | Manpower | Humidity Content |

300kg/hour | 125kw | 3ton/h | 3 | ≤5% |

500kg/hour | 260kw | 4-5ton/h | 3 | ≤5% |

700kg/hour | 450kw | 5ton/h | 4 | ≤5% |

1000kg/hour | 395kw | 6ton/h | 4 | ≤5% |

1600kg/hour | 960KW | 8ton/h | 6 | ≤5% |

Our Advantages

Advantages

1. Final products has good quality. When process PP PE film bags, final products humidity below 5%.

2. The machine with high efficiency, working stable, large capacity etc.

3. Parts which contact material use SUS304, thickness more than 3mm, ensure long service life time.

4. World famous brand components applied on the production line- SKF bearing, Siemens contactor, Japan RKC temperature, ABB invertor, Siemens PLC control.

1. Final products has good quality. When process PP PE film bags, final products humidity below 5%.

2. The machine with high efficiency, working stable, large capacity etc.

3. Parts which contact material use SUS304, thickness more than 3mm, ensure long service life time.

4. World famous brand components applied on the production line- SKF bearing, Siemens contactor, Japan RKC temperature, ABB invertor, Siemens PLC control.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

Laizhou Yisu Machinery Co., Ltd. is a professional production and processing company of recycling plastic pelletizer production line machine, chemical machinery, stone marble processing machine, agriculture garden machinery and other machine products, with a complete and scientific quality management system. The integrity, strength and product quality of Laizhou Yisu Machinery Co., Ltd. are recognized by the industry. Welcome friends from all walks of life to visit, guide and business negotiation.

FAQ

1. who are we?

We are based in Shandong, China. We are a national fixed-point enterprise specialized in recycling plastic pelletizer production line machinery, chemical machinery, agriculture garden machinery, woodworking machinery and stone marble processing machinery research and development. We have introduced advanced domestic and international technology, pay attention to technology reform and constantly develop new product. We shall make unremitting efforts to achieve in technology and service in the future self-improvement, and more to create and to provide customers the best products of real value, with first-class technology, first-class products and first class service to our customer side by side to meet the beautiful future.

2. how can we guarantee quality?

Always final innspection before shipment;

3.what can you buy from us?

recycling plastic pelletizer production line machine, chemical machine, stone marble processing machine, agriculture garden equipment etc.

4. why should you buy from us?

1) Can know machines' details technical specification and character.

2)Designing the machines and arrange the water, electric layout according to your requirement. Let you know production schedule through regular pictures, video, show the real production process to you. Provide turnkey project according to your requirement.

3)Invite you or your third party, to our factory to test, inspection machine before shipment, until you are satisfied.

4)Engineers are available to your factory for installation, commissioning, technical guidance and personnel training.

5)The equipment is completely free of charge for 12 months warranty. Spare parts are supplied with cost prices after 12 months after warranty time.

6)Establish the customer database, all the sold equipment can be checked any time.

7)Visit customers regularly, follow up the usage of each customer's equipment.

8)Improve product quality through advanced production management. Increase service stations gradually, effectively improve service and spare parts supply speed.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

We are based in Shandong, China. We are a national fixed-point enterprise specialized in recycling plastic pelletizer production line machinery, chemical machinery, agriculture garden machinery, woodworking machinery and stone marble processing machinery research and development. We have introduced advanced domestic and international technology, pay attention to technology reform and constantly develop new product. We shall make unremitting efforts to achieve in technology and service in the future self-improvement, and more to create and to provide customers the best products of real value, with first-class technology, first-class products and first class service to our customer side by side to meet the beautiful future.

2. how can we guarantee quality?

Always final innspection before shipment;

3.what can you buy from us?

recycling plastic pelletizer production line machine, chemical machine, stone marble processing machine, agriculture garden equipment etc.

4. why should you buy from us?

1) Can know machines' details technical specification and character.

2)Designing the machines and arrange the water, electric layout according to your requirement. Let you know production schedule through regular pictures, video, show the real production process to you. Provide turnkey project according to your requirement.

3)Invite you or your third party, to our factory to test, inspection machine before shipment, until you are satisfied.

4)Engineers are available to your factory for installation, commissioning, technical guidance and personnel training.

5)The equipment is completely free of charge for 12 months warranty. Spare parts are supplied with cost prices after 12 months after warranty time.

6)Establish the customer database, all the sold equipment can be checked any time.

7)Visit customers regularly, follow up the usage of each customer's equipment.

8)Improve product quality through advanced production management. Increase service stations gradually, effectively improve service and spare parts supply speed.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Recommend Products

Contact information:

kate

Skype: huirui7

Email: metprecise(at)163.com

kate

Skype: huirui7

Email: metprecise(at)163.com

Похожие товары

Вкусные капли Шоколадные Чипсы сливочное печенье хрустящее сладкое Сделано в Турции

10,00 $

Набор прокладок HFP2201606 для воздушного компрессора 6BT 5,9 QSB 4946293

1,50 $ - 3,80 $

Вакуумная Очищенная Соль PDV хлорид натрия

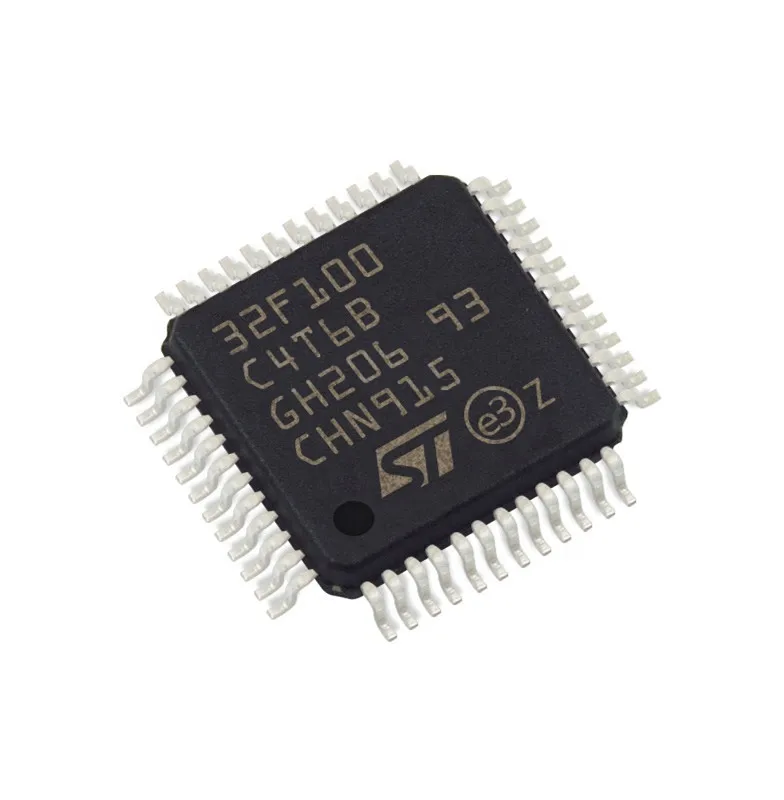

Микроконтроллеры STM32F100C4T6B IC MCU 32 бит 16 КБ FLASH 48LQFP Интегральные схемы ic chip STM32F100C4T6B

0,10 $

Домашняя уборка VIPaoclean, метла из натурального бука и металлическая мусорная сковорода с длинной ручкой

6,52 $

Передняя вилка мотоцикла амортизатор Крышка передняя вилка защита для 140cc 160cc питбайк Мотокросс мотоцикла защита от ударов

0,77 $ - 1,03 $

Высокое качество пнд гофрированные пластиковые дренажные трубы 300 400 800 900 SN 8 Спираль водопроводные трубы из полиэтилена высокой плотности разные размеры и цены 6 метров в длину

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $