Sevenstars 16 32 мм четыре полости ПВХ Электрический трубопровод машина для производства труб/экструдер/линия по производству труб

- Категория: >>>

- Поставщик: Zhangjiagang Sevenstars Machinery Co. Ltd.

Сохранить в закладки 1600835072703:

Описание и отзывы

Характеристики

General Introduction

PVC four cavities production line

Application and Features

Four cavities PVC electrical tube,water supply pipeextrusion line can extruder four pipes at same time on one machine.This line can save investment cost in factory buiding and production,which increase the capacity a lot and reduce production time. SJSZ65 conical twin-screw extruder can easily reach 5.5-6.5 ton/per day,the production speed take 16mm as example can get more than 8-10 m/min.

The whole line is composed of conical twin-screw extruder 65mm,4 cavity mould,4 cavity coling

calibration tank,4 station haul off,4 station cutter and 4 station tipping table.

The whole line is composed of conical twin-screw extruder 65mm,4 cavity mould,4 cavity coling

calibration tank,4 station haul off,4 station cutter and 4 station tipping table.

SJSZ series extuder

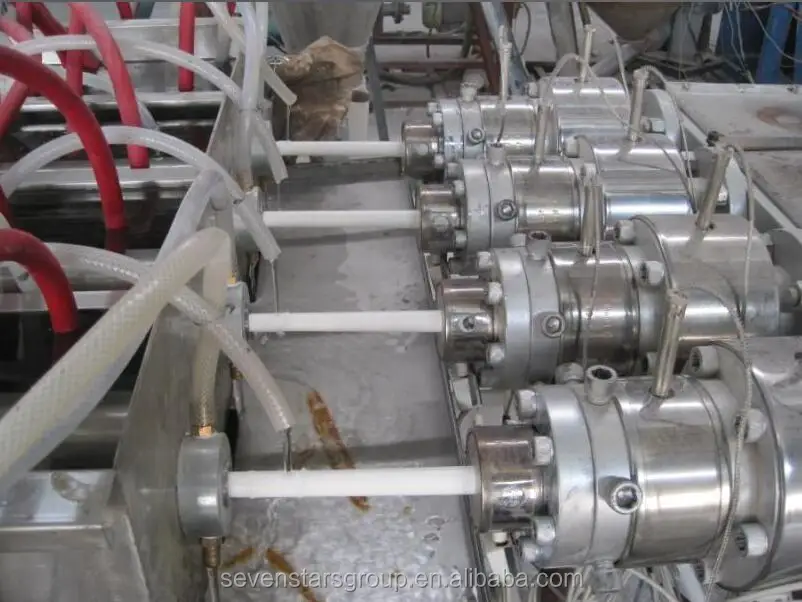

four cavity mould

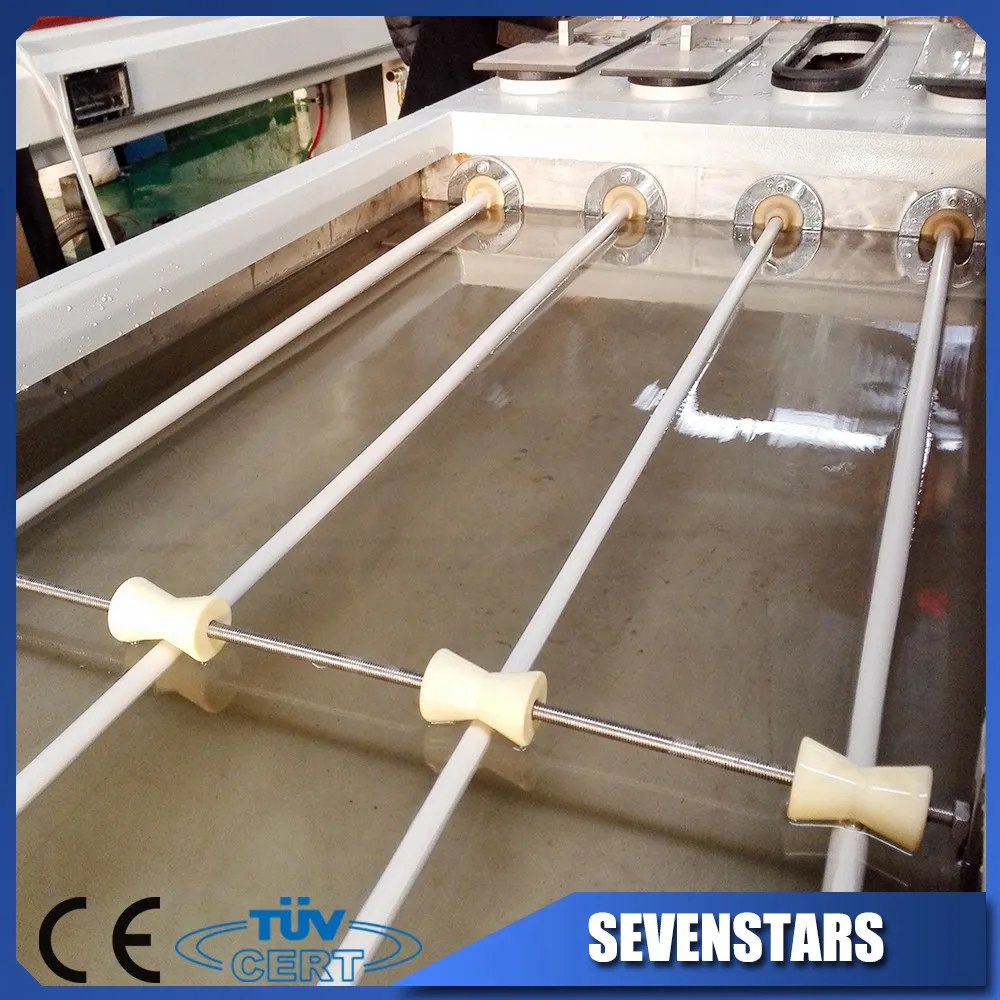

calibration

haul-off machine

cooling tank

stacker

final product

Main flow chat:

Raw material+additive → Mixing → granulating → Conveying feeding → Double screw extruder→Extrusion mould → Vocuum calibration machine → Stacker → Finished product inspecting & packing.

Parameters

Technical Parameter

products | screw diameter(mm) | Pipe Range(mm) | Capacity (kg/hr) | Main Motor Power (kw) | Total Power (kw) | Line Length (m) |

PVC32x4 | 80/156 | 16-32 | 300-400 | 55 | 200 | 22 |

PVC63x2 | 65/132 | 16-63 | 200-250 | 37 | 120 | 22 |

PVC63 | 51/105 | 16-63 | 80-120 | 18.5 | 50 | 22 |

PVC160 | 65/132 | 75-160 | 200-250 | 37 | 100 | 22 |

PVC250 | 65/132 | 110-250 | 200-250 | 37 | 120 | 30 |

PVC315 | 80/156 | 160-315 | 300-400 | 55 | 200 | 30 |

PVC450 | 80/156 | 200-450 | 300-400 | 55 | 220 | 36 |

PVC630 | 92/188 | 315-630 | 400-800 | 90 | 350 | 42 |

PVC800 | 92/188 | 500-800 | 400-800 | 110 | 400 | 45 |

Our team

Company

Zhangjiagang Sevenstars Machinery

Over the past 10 years, Sevenstars has grown to a medium-sized enterprises, of which the annual sale reaches nearly 70 million RMB. Our factory covers 26 acres, plant area of 20000 square meters. Now, our plastic machinery and equipment have been used in more than 100 countries and regions.

Packaging&shipping

Contact Me

FAQ

1. who are we?

We are based in Jiangsu, China, start from 2006,sell to South America(15.00%),Mid East(12.00%),Southeast Asia(10.00%),Africa(10.00%),Southern Europe(10.00%),South Asia(10.00%),Domestic Market(10.00%),North America(5.00%),Eastern Europe(5.00%),Western Europe(4.00%),Central America(2.00%),Oceania(00.00%),Eastern Asia(00.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Plastic Recycling Line,Plastic Pelletizing Line,Plastic Board Production Line,Plastic Profile Extrusion Line,Plastic Pipe Extrusion Production Line

4. why should you buy from us not from other suppliers?

We have factory, we can control both the manufacture of the machine materials and its fabrication into the finished product to ensure the dependability of our products. We have four modern standard workshops, we have our own skilled worker team, sales team

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,Escrow;

Language Spoken:English,Chinese

We are based in Jiangsu, China, start from 2006,sell to South America(15.00%),Mid East(12.00%),Southeast Asia(10.00%),Africa(10.00%),Southern Europe(10.00%),South Asia(10.00%),Domestic Market(10.00%),North America(5.00%),Eastern Europe(5.00%),Western Europe(4.00%),Central America(2.00%),Oceania(00.00%),Eastern Asia(00.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Plastic Recycling Line,Plastic Pelletizing Line,Plastic Board Production Line,Plastic Profile Extrusion Line,Plastic Pipe Extrusion Production Line

4. why should you buy from us not from other suppliers?

We have factory, we can control both the manufacture of the machine materials and its fabrication into the finished product to ensure the dependability of our products. We have four modern standard workshops, we have our own skilled worker team, sales team

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,Escrow;

Language Spoken:English,Chinese

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Похожие товары

Полная система 6 м, 12 м, передвижная лестница для строительных лесов

5,00 $ - 12,00 $

XRZ EEC высокомощный свинцово-кислотный аккумулятор 70 км/ч Максимальная скорость 3000 Вт 72 В уличный электрический мопед для взрослых

880,00 $

253647 STRON G.H бренд REGIS для швейных машин SINGER, 299U123 нитеобрезатель промышленных швейных машин и запасных частей

120,00 $ - 130,00 $

3225 14,31818 M SMD пассивные патчи-кристаллы, новый заводской кварцевый кристалл резонатор серии 3225 14,31818 M

Автоматическая машина для разделения утиного яичного желтка и белого скорлупа, машина для разделения яичного белка

8 800,00 $ - 12 500,00 $

1S Lipo зарядное устройство 3,7 в кабель для зарядки аккумулятора штекер и гнездо для RC квадрокоптера дрона мультикоптера

Xiaomi Mijia DC Переменная частота двухсезонного вентилятора BPLNSO1DM черный зима/лето двойного назначения 3-секундный быстрый нагрев

115,00 $ - 119,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $

Оригинальная популярная клавиатура для рабочего места Genos2 с 76 клавишами

200 $

Умный цифровой электронный ручной инфракрасный лазерный термометр для ветеринарного и медицинского мониторинга человека

5-10 $