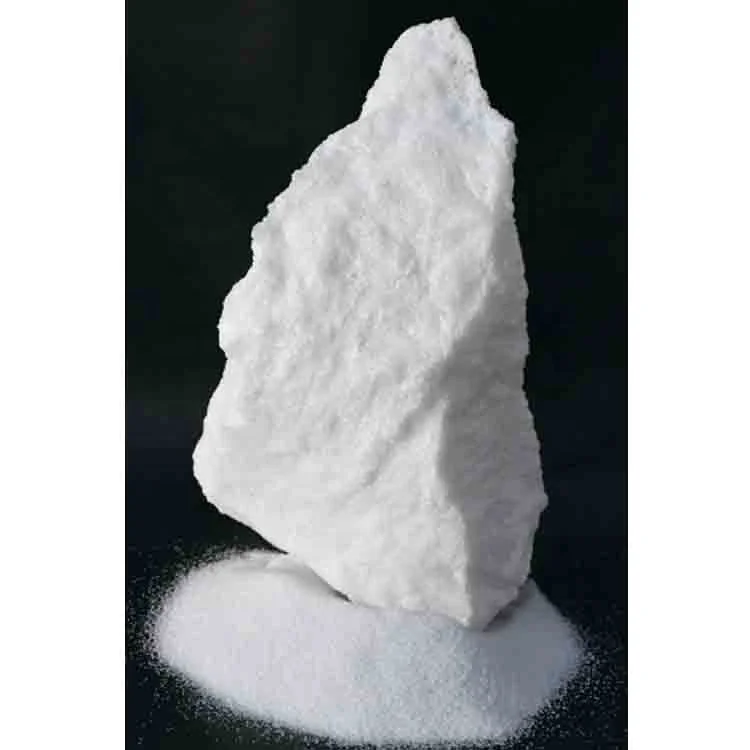

Профессиональное производство 98.5% высокое качество 50 нм порошок карбида кремния Sic для тонкой керамики Черный кремний

- Категория: Refractory >>>

- Поставщик: Hebei Suoyi New Material Technology Co. Ltd

Сохранить в закладки 1600837620998:

Описание и отзывы

Характеристики

Product Description

Specification

item | value |

Place of Origin | China |

Hebei | |

Shape | Powder |

Material | Silicon Carbide (SiC) |

Refractoriness (Degree) | 1770°< Refractoriness< 2000° |

CrO Content (%) | 0.0002 |

SiC Content (%) | 99.9% |

Model Number | SY-364 |

Brand Name | SUOYI |

Processing Service | Bending, Welding, Punching, Decoiling, Cutting |

Product name | Silicon carbide |

Formula | SiC |

Appearance | Black/Green Powder |

CAS NO. | 409-21-2 |

EINECS NO. | 206-991-8 |

HS Code | 2849200000 |

Purity | 99%-99.9% |

Particle size | 5um 15um 20um 45um |

Application | Ceramics, Refractories, Glass, Alloys |

Package | Drum/Barrel 25kgs/50kgs |

Application

Silicon carbide has four main application areas, namely: functional ceramics, advanced refractories, abrasives and metallurgical raw materials. Coarse silicon carbide materials can already be supplied in large quantities and cannot be regarded as a high-tech product. The application of nano-scale silicon carbide powder with extremely high technical content is unlikely to form economies of scale in a short time.

⑴As an abrasive, it can be used to make abrasive tools, such as grinding wheels, oilstones, grinding heads, sand tiles, etc.

⑵As a metallurgical deoxidizer and high temperature resistant material.

⑶ High-purity single crystals can be used to manufacture semiconductors and silicon carbide fibers.

Main application: used for wire cutting of 3-12 inch monocrystalline silicon, polycrystalline silicon, potassium arsenide, quartz crystal, etc. Engineering processing materials for the solar photovoltaic industry, semiconductor industry, and piezoelectric crystal industry.

Used in semiconductors, lightning rods, circuit components, high temperature applications, ultraviolet light detectors, structural materials, astronomy, disc brakes, clutches, diesel particulate filters, filament pyrometers, ceramic films, cutting tools, heating elements, nuclear fuels , Jewelry, steel, protective gear, catalyst carrier and other fields.

⑴As an abrasive, it can be used to make abrasive tools, such as grinding wheels, oilstones, grinding heads, sand tiles, etc.

⑵As a metallurgical deoxidizer and high temperature resistant material.

⑶ High-purity single crystals can be used to manufacture semiconductors and silicon carbide fibers.

Main application: used for wire cutting of 3-12 inch monocrystalline silicon, polycrystalline silicon, potassium arsenide, quartz crystal, etc. Engineering processing materials for the solar photovoltaic industry, semiconductor industry, and piezoelectric crystal industry.

Used in semiconductors, lightning rods, circuit components, high temperature applications, ultraviolet light detectors, structural materials, astronomy, disc brakes, clutches, diesel particulate filters, filament pyrometers, ceramic films, cutting tools, heating elements, nuclear fuels , Jewelry, steel, protective gear, catalyst carrier and other fields.

Packing & Delivery

50kgs/drum

Company Profile

Suoyi New Material Technology Company is strategically located in

Handan,which is a 3,000 years historical and cultural city locating in southwest of Hebei Province of China, adjacent to Shanxi and Henan province having convenient traffic condition.

Relying on the local abundant resources as well as the industry cluster advantage, Suoyi commits itself to research and develop advanced rare earth materials.

Suoyi New Material Technology Company now has fixed assets over 200 million RMB yuan. The company has more than 184 employees

among them about 80 technicians. Total production facility occupies more than 24000 m2 with four modern production lines of producing high purity rare earth oxides, rare earth salts and composites, rare earth metals & alloys as well as NdFeB magnets.

Products include full range of rare earth oxides, fluorides, acetates, nitrates, sulfates, metals & alloys with purity 99-99.9999%. Fine powder include Micronized, Sub-micron, Deep-submicron and nano particles. We also developed the application products like high performance NdFeB rare earth permanent magnets, high precision rare earth glass polishing powder and high grade synthetic additives for resins. Suoyi can customize the non-standardized materials according to customer's special requirements and is enthusiastic to provide the complete materials solution.

Products are used for metallurgy glass & ceramics,energy saving, spray coating, SOFC, biomedicines, photovoltaic power generation

electronic engineering, aerospace, military, polishing materials, grinding media . Our customers are all over the world.

Suoyi combines the business achievement, social responsibility and environment protection together. Through technology development

and innovation, Suoyi better serves customers' increasing demand for high function and value-added materials.

Suoyi aims to be the world leading rare earth materials company, accompanying you exploring the mysteries of rare earth elements.

The slogan 'Discover Rare Earth, You+Me'encourages us to explore and create new values of rare earth. Simultaneously, Suoyi continues to establish itself internationally a world class brand.

Suoyi strives to provide the best answers and solution to its customers about rare earth.

Handan,which is a 3,000 years historical and cultural city locating in southwest of Hebei Province of China, adjacent to Shanxi and Henan province having convenient traffic condition.

Relying on the local abundant resources as well as the industry cluster advantage, Suoyi commits itself to research and develop advanced rare earth materials.

Suoyi New Material Technology Company now has fixed assets over 200 million RMB yuan. The company has more than 184 employees

among them about 80 technicians. Total production facility occupies more than 24000 m2 with four modern production lines of producing high purity rare earth oxides, rare earth salts and composites, rare earth metals & alloys as well as NdFeB magnets.

Products include full range of rare earth oxides, fluorides, acetates, nitrates, sulfates, metals & alloys with purity 99-99.9999%. Fine powder include Micronized, Sub-micron, Deep-submicron and nano particles. We also developed the application products like high performance NdFeB rare earth permanent magnets, high precision rare earth glass polishing powder and high grade synthetic additives for resins. Suoyi can customize the non-standardized materials according to customer's special requirements and is enthusiastic to provide the complete materials solution.

Products are used for metallurgy glass & ceramics,energy saving, spray coating, SOFC, biomedicines, photovoltaic power generation

electronic engineering, aerospace, military, polishing materials, grinding media . Our customers are all over the world.

Suoyi combines the business achievement, social responsibility and environment protection together. Through technology development

and innovation, Suoyi better serves customers' increasing demand for high function and value-added materials.

Suoyi aims to be the world leading rare earth materials company, accompanying you exploring the mysteries of rare earth elements.

The slogan 'Discover Rare Earth, You+Me'encourages us to explore and create new values of rare earth. Simultaneously, Suoyi continues to establish itself internationally a world class brand.

Suoyi strives to provide the best answers and solution to its customers about rare earth.

Our Services

FAQ

1. who are we?

We are based in Hebei, China, start from 2014,sell to Southern Europe(13.00%),North America(12.00%),Central America(12.00%),Eastern Europe(10.00%),Southeast Asia(10.00%),Mid East(10.00%),Eastern Asia(10.00%),Western Europe(10.00%),Africa(8.00%),South Asia(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Rare Earth/Yttrium Oxide/Zirconium Dioxide,Yttria Stabilized Zirconia/Aluminum Oxide

4. why should you buy from us not from other suppliers?

null

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,FCA,DAF;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Japanese,German,French

We are based in Hebei, China, start from 2014,sell to Southern Europe(13.00%),North America(12.00%),Central America(12.00%),Eastern Europe(10.00%),Southeast Asia(10.00%),Mid East(10.00%),Eastern Asia(10.00%),Western Europe(10.00%),Africa(8.00%),South Asia(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Rare Earth/Yttrium Oxide/Zirconium Dioxide,Yttria Stabilized Zirconia/Aluminum Oxide

4. why should you buy from us not from other suppliers?

null

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,FCA,DAF;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Japanese,German,French

Похожие товары

Огнеупорный цемент высокой чистоты огнеупорный бесплатный

0,38 $ - 0,48 $

Лучшая цена Белый Плавленый оксид алюминия белый алунд корунд для абразивных и огнеупорных

Термостойкий и кислотостойкий кирпич Nanxiang от производителя кислотный аккумулятор

500,00 $

Огнеупорные изделия огнеупорный цемент и кремниевый порошок высокое содержание кремния высококлассное

240,00 $ - 250,00 $

YDGM-30 огнеупорный сварной перфорированный кирпич из глинозема

1 045,00 $

YDGM-30 муллитовый Теплоизоляционный глиноземный глиняный кирпич, огнеупорный перфорированный огнеупорный кирпич

Rongsheng Высокое Качество Спеченный Магнезит КИРПИЧ для туннельных печей

Новые поступления

Новинки товаров от производителей по оптовым ценам

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $