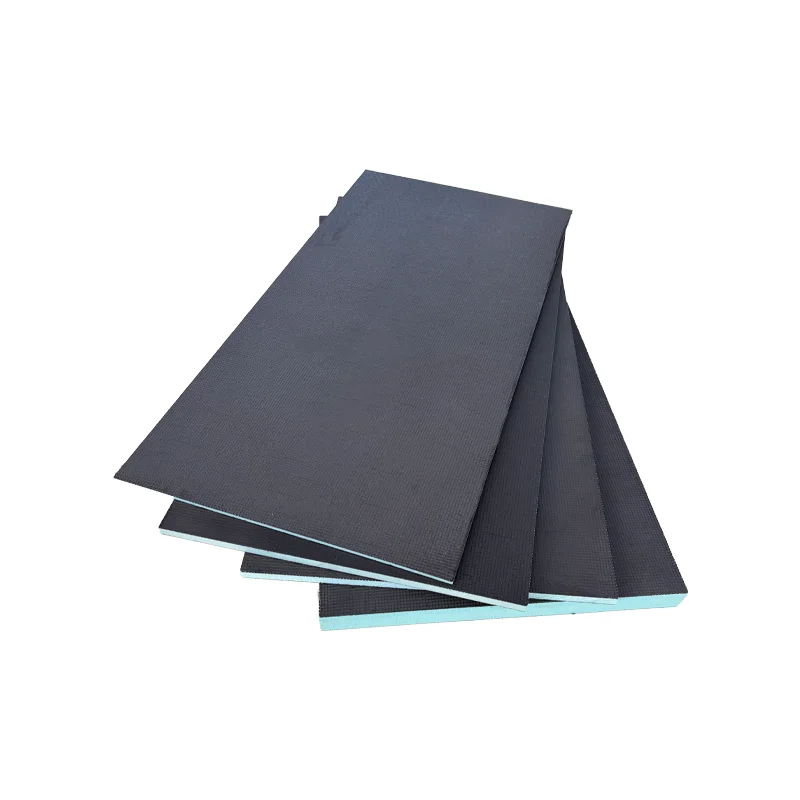

Пенопластовый лист водонепроницаемая настенная плитка стеновая панель из пенополистирола высокого качества экструдированный пластиковый пакет полистирола современный

- Категория: >>>

- Поставщик: Shanghai Taichun Energy Saving Technology Co. Ltd.Shanghai Ltd.

Сохранить в закладки 1600844839013:

Описание и отзывы

Характеристики

Why Choose Us

Products Description

What is the use of XPS foam sheet

xps extruded board main use and application field.

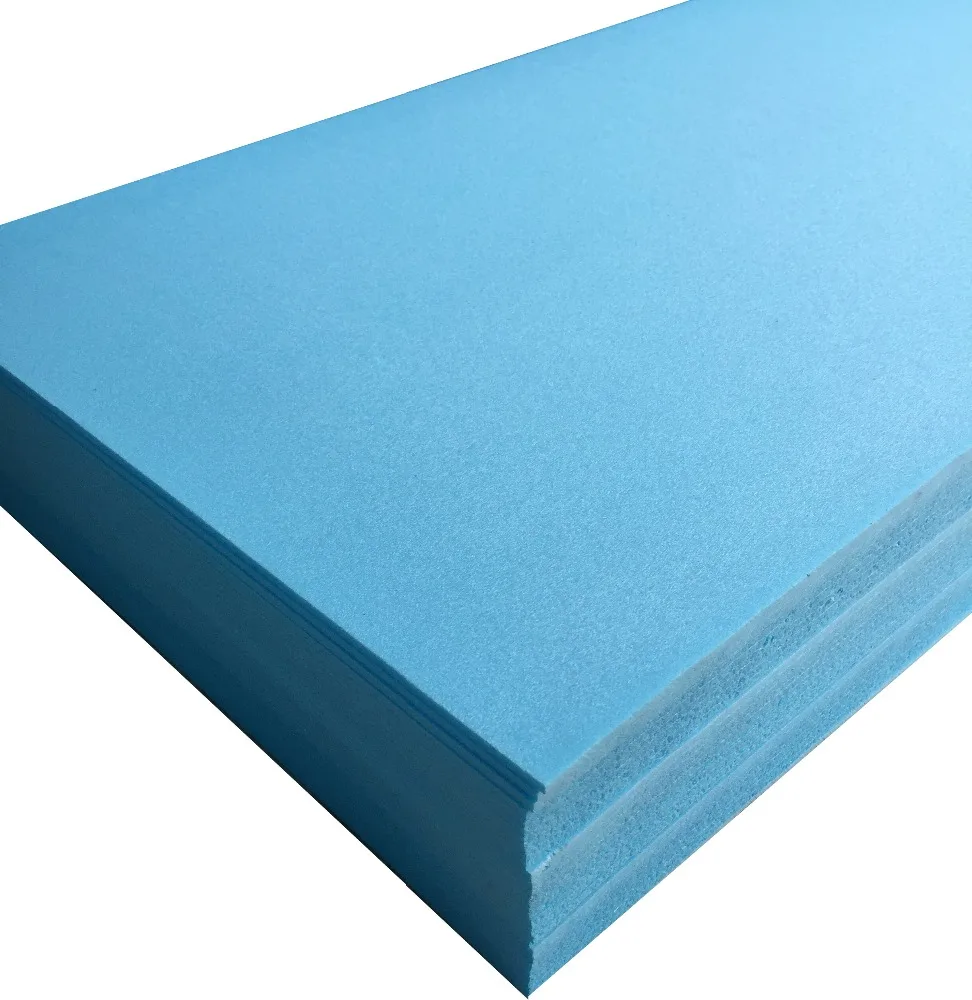

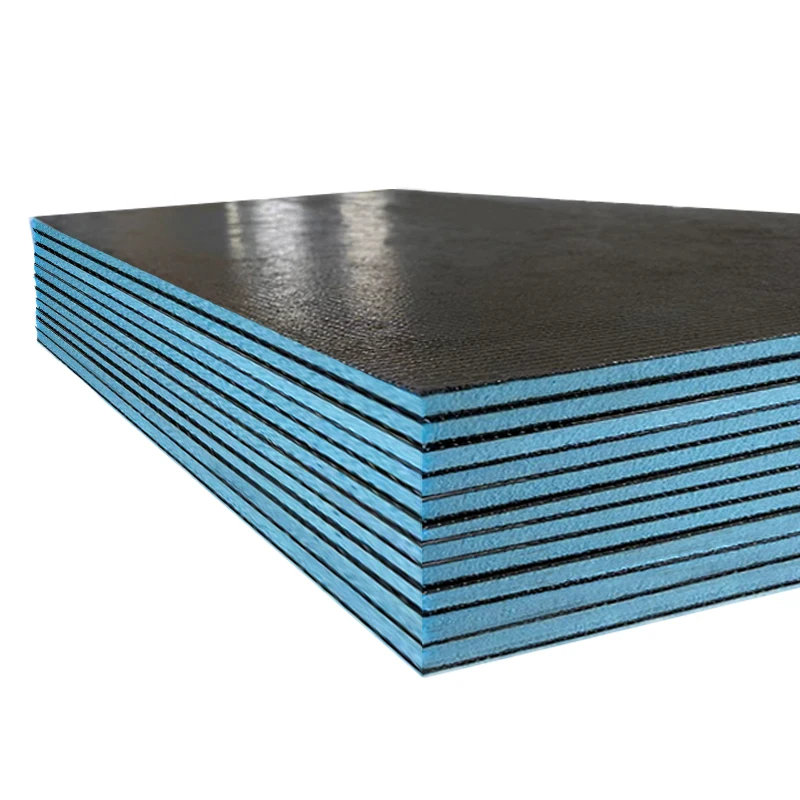

xps extruded panels can be used for ground paving, airport roads and highway foundations. The extrusion plate is waterproof and moisture-proof, and is not easy to deteriorate or seep water, which can reasonably and effectively slow down the subgrade collapse caused by road leakage.

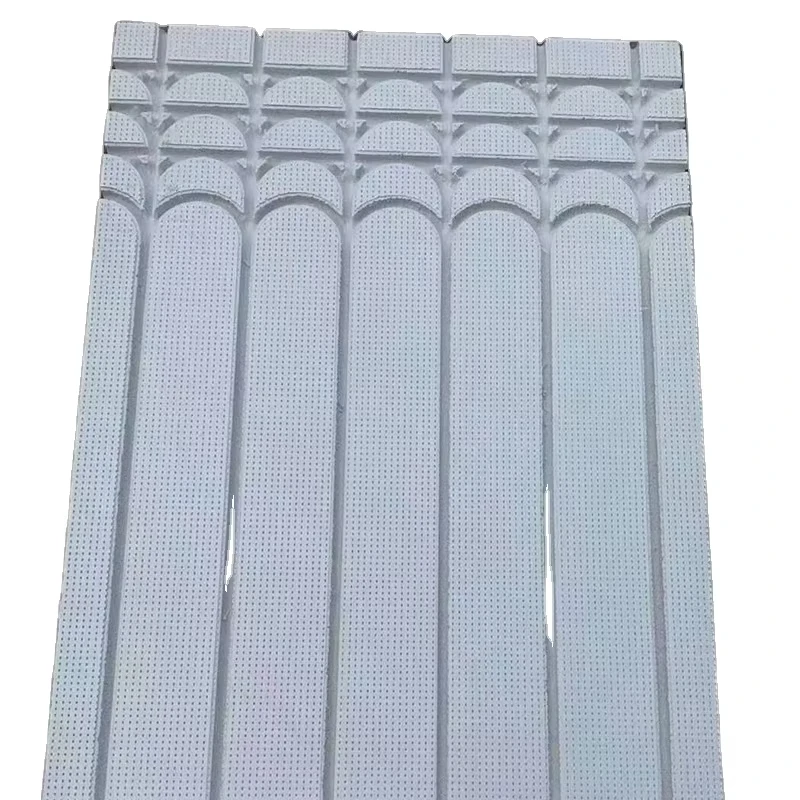

Extruded plate is an indispensable material in cold storage construction. It not only plays the role of heat insulation, but also because of the microporous structure on the surface of the extruded board, can absorb and buffer a small amount of water vapor condensation, reducing the formation of water droplets. Special cold storage cold storage insulation board needs a very high thickness, more than 10cm. Therefore, in the construction of cold storage, usually use two layers of cold storage insulation board. One is to increase the thickness, and the other is to stagger the two layers of plastic extruded board to increase the thermal insulation performance and avoid temperature loss.

Floors and exterior walls can also be insulated with flame retardant panels.

xps extruded boards are now used more in home decor. First of all, the extruded board is not very hard, indoors, stepping on people's feet will have some cushion. Feet feel very comfortable, not so hard, we call it floor mat treasure. One such purpose is the floor Mat, a type of extruded board that is stronger, larger, thinner and flame retardant free than exterior extruded board.

To place furniture mainly indoors, but also need to do a good job for years and months of activities, need the corresponding intensity; Extruded panels are constructed with honeycomb closed cell frames to ensure that only thin layers can be used. Comes with better insulation, waterproof, moisture-proof effect, indoor floor is limited. Compared with home decoration, the thinner the foundation, the larger the space environment, the more comfortable the activities. Extruded board in the room is generally 2 cm thick, the thickness is enough.

xps extruded panels can be used for ground paving, airport roads and highway foundations. The extrusion plate is waterproof and moisture-proof, and is not easy to deteriorate or seep water, which can reasonably and effectively slow down the subgrade collapse caused by road leakage.

Extruded plate is an indispensable material in cold storage construction. It not only plays the role of heat insulation, but also because of the microporous structure on the surface of the extruded board, can absorb and buffer a small amount of water vapor condensation, reducing the formation of water droplets. Special cold storage cold storage insulation board needs a very high thickness, more than 10cm. Therefore, in the construction of cold storage, usually use two layers of cold storage insulation board. One is to increase the thickness, and the other is to stagger the two layers of plastic extruded board to increase the thermal insulation performance and avoid temperature loss.

Floors and exterior walls can also be insulated with flame retardant panels.

xps extruded boards are now used more in home decor. First of all, the extruded board is not very hard, indoors, stepping on people's feet will have some cushion. Feet feel very comfortable, not so hard, we call it floor mat treasure. One such purpose is the floor Mat, a type of extruded board that is stronger, larger, thinner and flame retardant free than exterior extruded board.

To place furniture mainly indoors, but also need to do a good job for years and months of activities, need the corresponding intensity; Extruded panels are constructed with honeycomb closed cell frames to ensure that only thin layers can be used. Comes with better insulation, waterproof, moisture-proof effect, indoor floor is limited. Compared with home decoration, the thinner the foundation, the larger the space environment, the more comfortable the activities. Extruded board in the room is generally 2 cm thick, the thickness is enough.

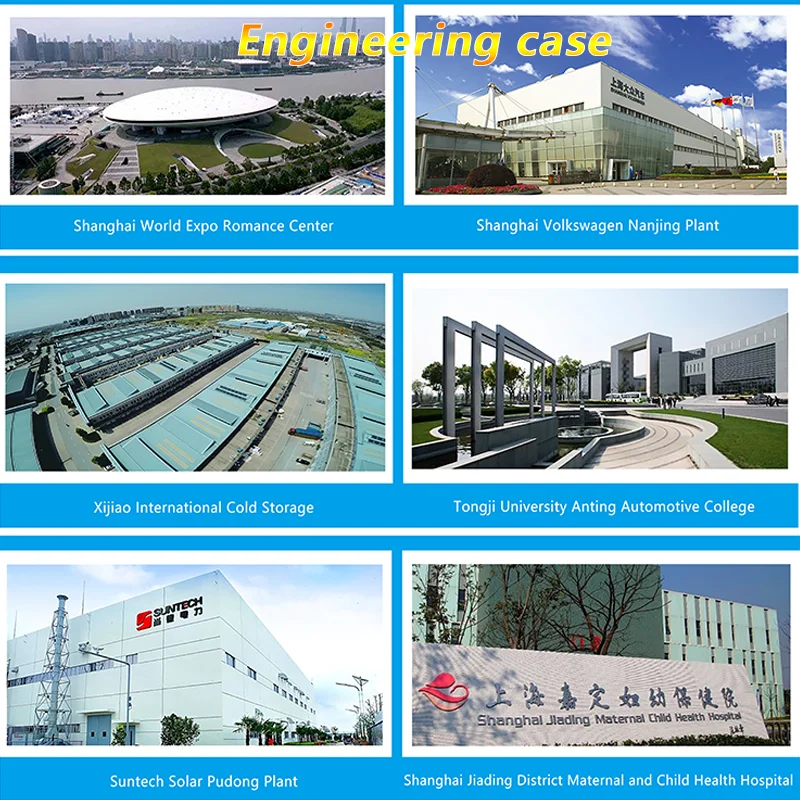

Company Profile

Advantages

1, OEM & ODM service;

2, Own R&D, Free design/artwork service;

3, Professional Sales Operations Team;

4, We have a variety of special equipment to meet all kinds of bags production;

5, There are many kinds of products to meet your shopping needs;

6, Our strict and fair quality control department ensures the quality of your products;

7, For any questions orsuggestions, please contact us.

Product packaging

Contact Us

Похожие товары

Экструдированные строительные блоки xps из пеноматериала с закрытыми ячейками для зданий

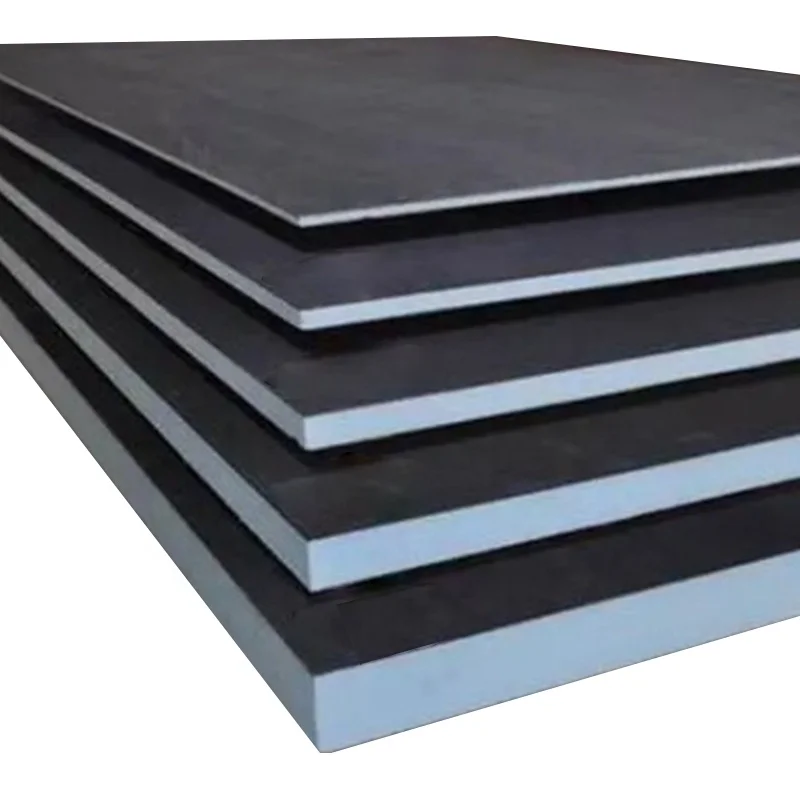

Отличная теплоизоляция XPS теплоизоляционная плита водонепроницаемый жесткий полистирольный материал Стекловолоконные сетчатые панели настенные доски

2,00-3,00 $

Китайские Производители напрямую поставляют XPS пенополистирол экструдированный пеноизоляционную панель

Распродажа низкая цена пенополистирол изоляционная плита из пенополистирола

1,50-2,00 $

Xinruida настраиваемые прочные подпорные панели 10 мм Водонепроницаемые Полистирольные XPS сэндвич-панели для настенного применения

Цена по прейскуранту завода толщина 3 см высокая плотность и высокое качество панель XPS с алюминиевой фольгой для подогрева воды

2,19-2,79 $

Легкая цементная доска низкой плотности с 6 мм/8 мм/10 мм Титульная

3,00-4,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $