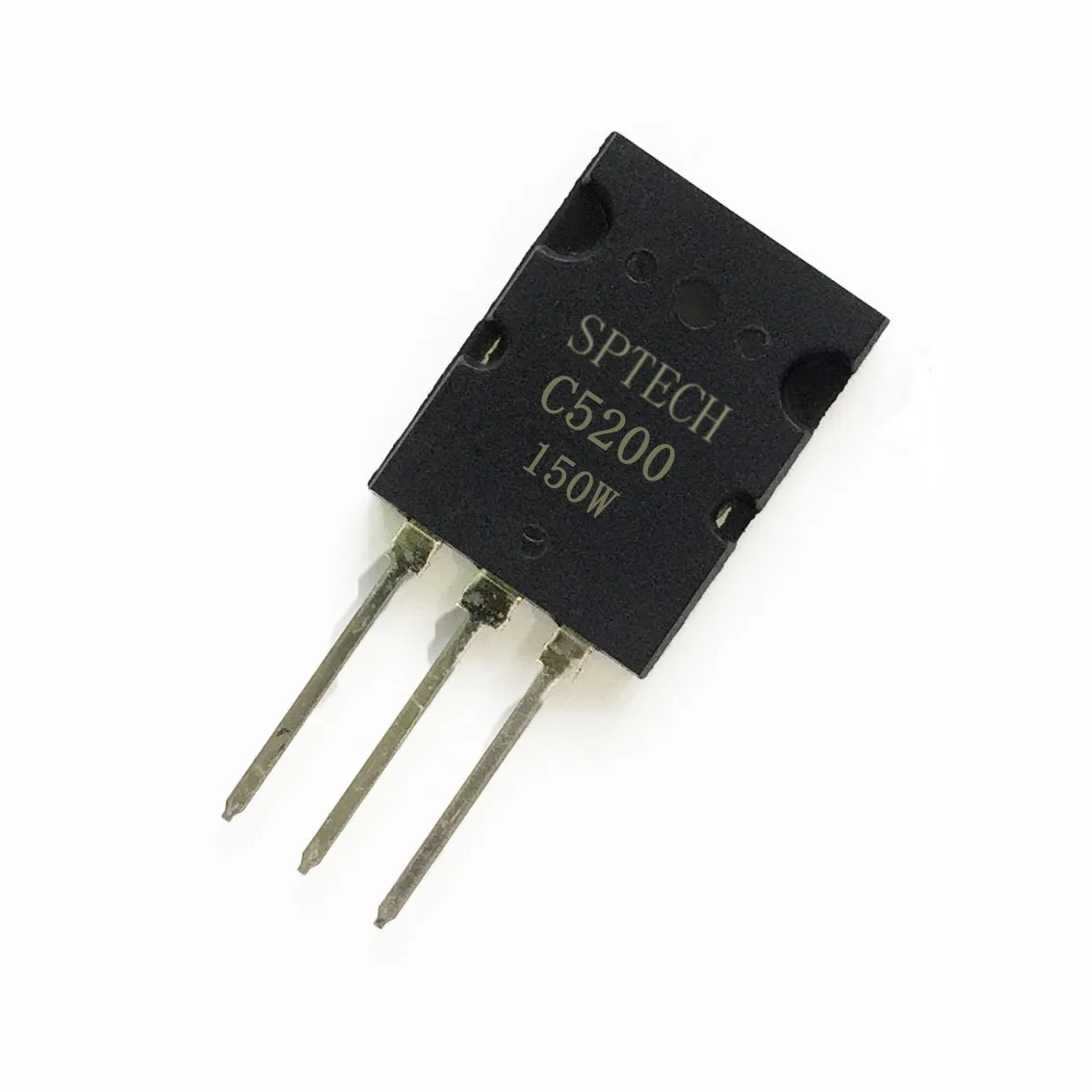

T618 t2f smd tl431 транзистор 4n65 3052 В 2sk3603 2sk1940 2sc1971 2sa1302 2n0807 2 sk 1389 16 a 13002 12nm50nd 102 040n06n

- Категория: >>>

- Поставщик: Finest PCB Assembly Limited

Сохранить в закладки 1600848202938:

Описание и отзывы

Характеристики

Our Service

Finest PCB Assembly is a 18 years one-stop solution provide: *PCB manufacturing

*Components sourcing

*PCB assembly

*Firmware programming

*PCBA functional test

*Plastic/Metal case assembly

*Components sourcing

*PCB assembly

*Firmware programming

*PCBA functional test

*Plastic/Metal case assembly

PCB Specification: | ||||||||||

PCB layers: | 1-24layers | |||||||||

PCB materials: | CEM1, CEM3, Teflon, Rogers, FR-4, High Tg FR-4, Aluminum Base, Halogen Free | |||||||||

PCB max. board size: | 620*1100mm (Custom) | |||||||||

PCB certificate: | RoHS Directive-Compliant | |||||||||

PCB Thickness: | 1.6 ±0.1mm | |||||||||

Out Layer Copper Thickness: | 0.5-5oz | |||||||||

Inner Layer Copper Thickness: | 0.5-4oz | |||||||||

PCB max. board thickness: | 6.0mm | |||||||||

Minimum Hole Size: | 0.20mm | |||||||||

Minimum Line Width/Space: | 3/3mil | |||||||||

Min. S/M Pitch: | 0.1mm(4mil) | |||||||||

Plate Thickness and Aperture Ratio : | 30:1 | |||||||||

Minimum Hole Copper: | 20µm | |||||||||

Hole Dia. Tolerance(PTH): | ±0.075mm(3mil) | |||||||||

Hole dia. Tolerance(NPTH): | ±0.05mm (2mil) | |||||||||

Hole Position Deviation: | ±0.05mm (2mil) | |||||||||

Outline Tolerance: | ±0.05mm (2mil) | |||||||||

PCB solder mask: | Black, white, yellow | |||||||||

PCB surface finished: | HASL Leadfree,Immersion ENIG,Chem Tin,Flash Gold,OSP,Gold finger,Peelable,Immersion Silver | |||||||||

Legend: | White | |||||||||

E-test: | 100% AOI, X-ray, Flying probe test. | |||||||||

Outline: | Rout and Score/V-cut | |||||||||

Inspection Standard: | IPC-A-610CCLASSII | |||||||||

Certificates: | UL (E503048),ISO9001/ISO14001/IATF16949 | |||||||||

Outgoing Reports: | Final Inspection, E-test, Solderability Test, Micro Section and More | |||||||||

PCBA Technical Capability | |

1. Assembly Type:: | FR4, FPC, Rigid-flex PCB, Metal base PCB. |

2. Assembly Specification: | Min size L50*W50mm; Max size: L510*460mm |

3. Assembly thickness: | Min thickness: 0.2mm; Max thickness: 3.0mm |

4. Components Specification | |

Components DIP: | 01005Chip/0.35 Pitch BGA |

Minimum device accurace: | +/-0.04mm |

Minimum footprint distance: | 0.3mm |

5. File format: | BOM list; PCB Gerber file: |

6. Test | |

IQC: | Incoming inspection |

IPQC: | Production inspection; first ICR test |

Visual QC: | Regularly quality inspection |

SPI test : | Automatic solder paste optical inspection |

AOI: | SMD component welding detection, components shortage & component polarity detection |

X-Ravd: | BGA test; QFN and other precision devices hidden PAD device inspection |

Function test: | Test function and performance according to customer's test procedures and steps |

7. Reworking: | BGA rework equipment |

8. Delivery Time | |

Normal delivery time: | 24 hours( fastest 12 hours quick-turn) |

Small production: | 72 hours( fastest 24 hours quick-turn) |

Medium production: | 5 working davs. |

9. Capacity: | SMT assembly 5 million point/day;plug-in & welding 300,000 point/day; 50-100 items/day |

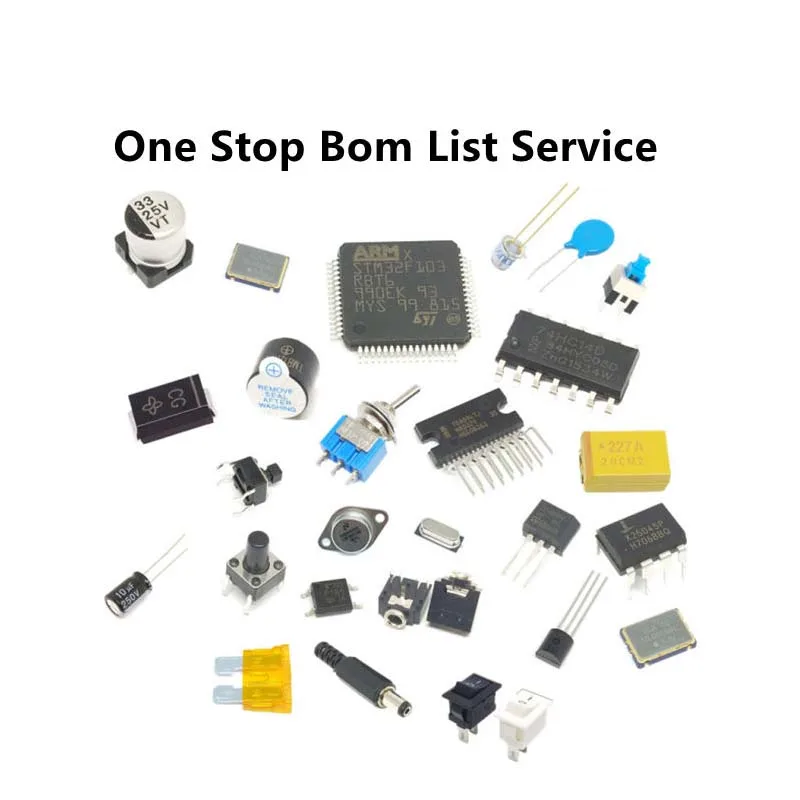

10. Components Service | |

A full set of substitute materials: | Have a experience component procurement sourcing, management system, and provide cost-effective services for OEM projects |

Only SMT: | Do SMT and backhand welding according to components PCB boards provided by customers. |

Components purchasing: | Customers provide core components, and we provide components sourcing services. |

Our Advantages

Why choose Finest PCB Assembly?

1.More than 18 years experience of electronic manufacturing sevices for PCB making.

2.One stop service | PCB Manufacturing | Components sourcing and PCB assembly to help you easily achieve your electronic products.

3.more than 1000 customers working with us telecom, IOT, RF, smart control, security,medical,industrial,automotive, 3G / 4G / 5G products.

4.Reasonable and stable price: have established a strong global electronics components supply chain that help us get reasonable and stable pric

5.Quality assurance: more than 15 years experienced engineering team and quality control team to ensure all products come out under control.

6.Professional replace-solution: help customers source professional replace-solution to achieve faster, lower cost with high quality components purchasing agent servic

1.More than 18 years experience of electronic manufacturing sevices for PCB making.

2.One stop service | PCB Manufacturing | Components sourcing and PCB assembly to help you easily achieve your electronic products.

3.more than 1000 customers working with us telecom, IOT, RF, smart control, security,medical,industrial,automotive, 3G / 4G / 5G products.

4.Reasonable and stable price: have established a strong global electronics components supply chain that help us get reasonable and stable pric

5.Quality assurance: more than 15 years experienced engineering team and quality control team to ensure all products come out under control.

6.Professional replace-solution: help customers source professional replace-solution to achieve faster, lower cost with high quality components purchasing agent servic

Base Material | FR-4 |

Copper Thickness | 1OZ |

Board Thickness | 0.2mm |

Min. Hole Size | 0.25mm |

Min. Line Width | 4mil |

Min. Line Spacing | 4mil |

Aspect ratio | 8:1 |

Max layer | 16 layers |

Min. hole size | 10mil |

Min. line width/space | 0.1mm |

Max. Board size | 59in*22in |

Hole position tolerance | +/-0.076mm |

Routing outline tolerance | +/-0.13mm |

Punching outline tolerance | +/-0.05mm |

Production capability | 40,000 s.q.m/month |

Surface finished | Lead free HASL, immersion gold (ENIG), hard gold, gold fingers, immersion silver, immersion Tin, OSP etc. |

Our Services

Finest PCB Assembly is a 18 years one-stop solution provide:

*PCB manufacturing

*Components sourcing

*PCB assembly

*Firmware programming

*PCBA functional test

*Plastic/Metal case assembly

*PCB manufacturing

*Components sourcing

*PCB assembly

*Firmware programming

*PCBA functional test

*Plastic/Metal case assembly

Products Show

Single-Layer PCBs

Single Sided PCBs are made out of substrate that is then coated in a thin layer of metal—typically copper—and a solder mask. Manufacturers etch and apply electronic components to only one side of the circuit board. These PCBs are easy to produce and have a very low cost, especially when manufactured in large quantities. They are the most commonly used type of PCB, finding use in consumer, commercial, and industrial electronic equipment.

Double-Layer PCBs

Double-layer PCBs have the same basic makeup as single-layer printed circuit boards, but they have circuits and other components on both sides of the boards. Vias (i.e., channels) running through the board allow circuits on one side of the board to communicate with parts on the other side of the board. These PCBs increase the amount of functional surface area available for circuits without increasing the amount of physical space needed.

Multi-Layer PCBs

Multi-layer PCBs have three or more laminated between the external layers of the solder mask. The use of insulation prevents the buildup of excessive heat that can melt sensitive components. This type of PCB ranges in the level of complexity—from 4 to 50 layers in thickness—and can accommodate complex and complicated tasks. Applications include data storage, GPS devices, satellite systems, and complex medical equipment.

Company Profile

Finest PCB Assembly Limited is also a subsidiary of FINEST Group, which was established in April 2003, focusing on PCB board manufacturing, SMT processing, and component support services. In April 2019, we set up Finest SMT factory, specializing in EMS processing, fast SMT proofing, and small batch production. With the ability of material selection, sample making, small batch production, and testing services, we are capable to improve the efficiency of research and development to provide faster services.

Exhibition

FAQ

1. who are we?

We are based in Guangdong, China, start from 2019,sell to Domestic Market(50.00%),North America(15.00%),South America(12.00%),Northern Europe(12.00%),Western Europe(5.00%),Southeast Asia(2.00%),Mid East(2.00%),Eastern Europe(2.00%). There are total about 301-500 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

PCBA,PCB Assembly,PCBA Board,LED PCBA,Electronic PCBA

4. why should you buy from us not from other suppliers?

*A 18-year one-stop solution provider

*Strong R&D group with 30 engineers

*Monthly output:45000 sqm of PCBs and PCBAs

*4500-square-meter factory

*Eight SMT production-line

*Automatic SMT, Reflow machine, AOI&x-RAY

*Fast response, reply within 24hrs

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,GBP;

Accepted Payment Type: T/T,L/C,MoneyGram,Western Union;

Language Spoken:English,French

We are based in Guangdong, China, start from 2019,sell to Domestic Market(50.00%),North America(15.00%),South America(12.00%),Northern Europe(12.00%),Western Europe(5.00%),Southeast Asia(2.00%),Mid East(2.00%),Eastern Europe(2.00%). There are total about 301-500 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

PCBA,PCB Assembly,PCBA Board,LED PCBA,Electronic PCBA

4. why should you buy from us not from other suppliers?

*A 18-year one-stop solution provider

*Strong R&D group with 30 engineers

*Monthly output:45000 sqm of PCBs and PCBAs

*4500-square-meter factory

*Eight SMT production-line

*Automatic SMT, Reflow machine, AOI&x-RAY

*Fast response, reply within 24hrs

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,GBP;

Accepted Payment Type: T/T,L/C,MoneyGram,Western Union;

Language Spoken:English,French

Похожие товары

XTRONS 8,8 дюймовый автомобильный android экран autoestereo головное устройство для BMW 3 серии E90 E91 E92 E93 CIC с беспроводной CarPlay Android авто

245,00 $ - 286,00 $

Инженерные пластиковые Поливинилиден фторид гомо-полимерные частицы PVDF W1300 PVDF порошок гранулы

40,00 $ - 70,00 $

Семинар Сварки Деталей Затемнение Сварщик Оборудование Материал PP Сварочный Шлем С

KTC4377-RTF/P SOT-89 ICS Controllers LVDT Transducers

1,90 $ - 3,30 $

Высокое качество Профессиональный зеленого цвета, бензин бензопила цена

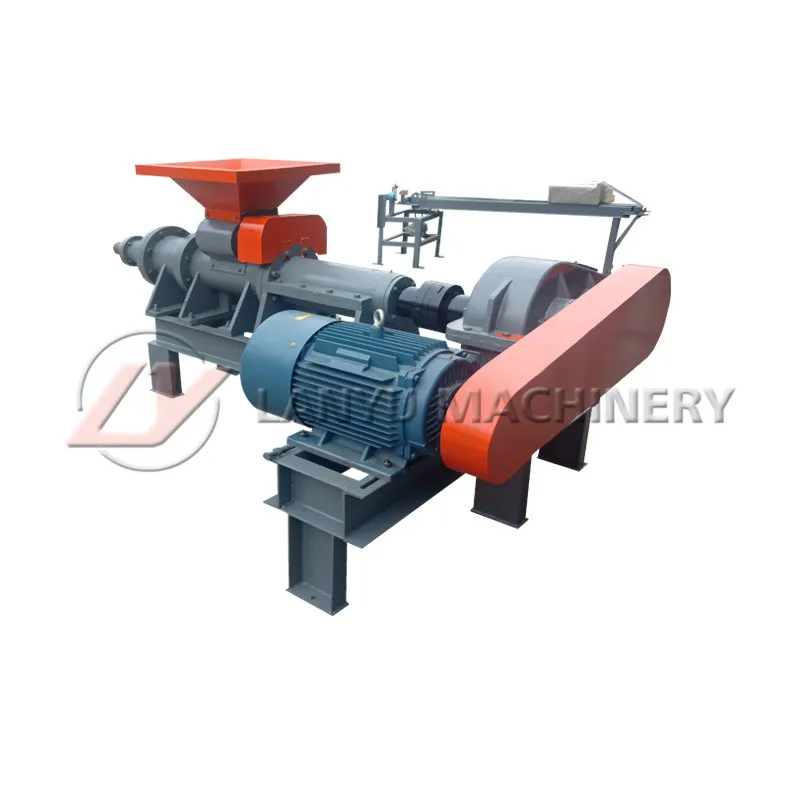

Машина Для Брикетирования коксового угля, машина для производства коксового брикета, машина для брикетирования коксового порошка

1 999,00 $

Новый выпрямительный тормозной модуль ESD141/ESD138B/ESD138C/NM181NR4/REC12-690

510,00 $ - 520,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $