Круглая металлическая вибро шейкер

- Категория: >>>

- Поставщик: Xinxiang Dayong Vibration Equipment Co. Ltd.

Сохранить в закладки 1600848887032:

Описание и отзывы

Характеристики

Salt Coal And Poultry Feed Round Metal Tumbler Vibro Shaker Screen Machine

Model | Diameter(mm) | Screening surface(m²) | Layer | Power |

DYB-800 | 800 | 0.292 | 1-5 | 0.25 |

DYB-1000 | 1000 | 0.785 | 1-5 | 1.5 |

DYB-1200 | 1200 | 1.13 | 1-5 | 2.2 |

DYB-1600 | 1600 | 1.83 | 1-5 | 3 |

DYB-2000 | 2000 | 2.63 | 1-5 | 4.0 |

DYB-2400 | 2400 | 4.52 | 1-5 | 5.5 |

DYB-2600 | 2600 | 5.31 | 1-5 | 5.5 |

Q: What information do we need to help you choose a perfect machine?

1. Name and feature of the raw material

2.Aim of using: get rid of impurity, filtration, grading

3.granularity distribution

4.Handling capacity: kg /h, L/h

5.The raw material size: (mesh or mm)

6.The moisture of the material

7.The material of construction (stainless steel SUS 304 or 316, carbon steel Q 235 A)

8.How many layers you need?

9.The voltage , frenquency, phase (single or three)

Note: You'd better send us the relevent pictures or some materials you want to sift , it can assure us to recommend the suitable machine for you.

Q:Can I ask some special and customize design?

A: Yes, we can make a suitable machine for you according to your request.

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

Xinxiang Dayong Vibration Equipment Co., Ltd. specializes in manufacturing series of vibrating screen, and we could design, develop and produce by ourselves. At present, the main range of products include kinds of series of vibrating screens, vibrating separator and filter, ultrasonic vibrating screens, sifting machines, filtering machines, linear vibrating screens, testing screens, screw conveyor, bucket elevator, honey processing machine, grain cleaning machine, etc. We have our design team, and can design machine according your requirement. If you have any needs or questions, please don't hesitate to contact us, we shall be pleased to be of service to you at all times.

Q: How many kinds of material are supported?

A. All stainless steel (201, 304, 316L)

B. All carbon steel Q235A

C. Contact part Stainless steel.

Q: How to select a suitable vibrating screen?

A. what’s the material and its density?

B. what’s the mesh size? And which size of powder do you need?

C. What’s the percentage of every size in your material?

D. What’s your excepted capacity?

Q: Any self-cleaning devices on the sieving machine?

Yeah, Bouncing ball, Ultrasonic system and other self-cleaning devices could be installed.

Похожие товары

Отдельностоящая электрическая плита для макаронных изделий, кухонное оборудование для приготовления пищи, 6 корзин, электрическая плита для макаронных изделий

Лучшая цена волоконно-оптический ларингоскоп с Macintosh Miller McCoy Blade

Женская Шапка-бини с помпоном, шарф, Милая зимняя Лыжная шапка для девочек, вязаная шапка с напуском и черепом, с флисовой подкладкой

EW-20D мини машина для обмотки провода свертываясь спиралью машина semi автоматическая машина для кабельных стяжек

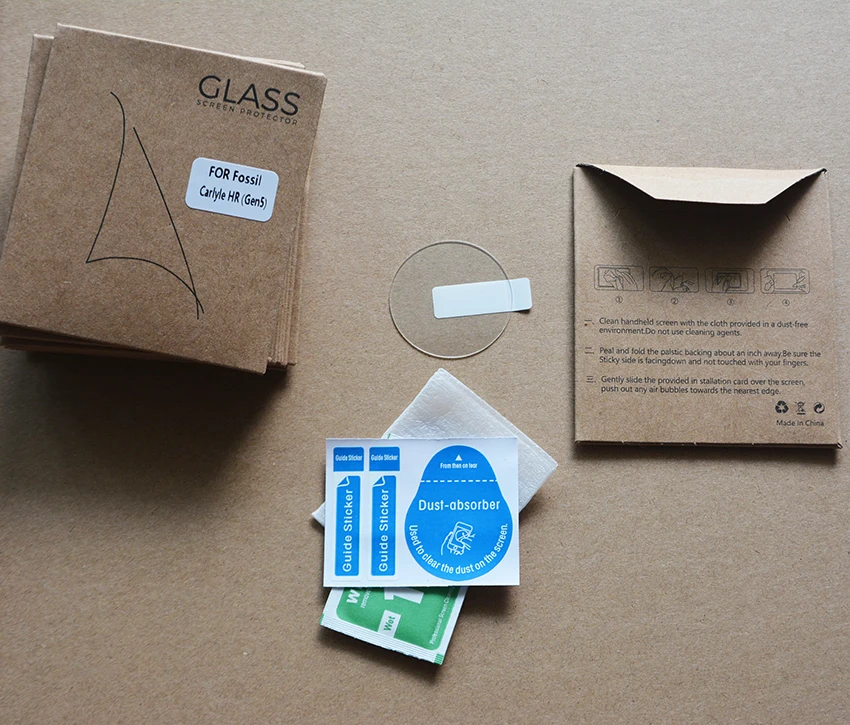

Суперпрозрачное закаленное стекло 9H 2.5D 0,3 мм, Защита экрана для Fossil Carlyle HR Gen 5 Смарт-часов

Щелочное сопротивление стирол акриловый полимер Стекловолоконная Смола RF-302

Высокомарганцовистая сталь крышкой и накидкой, костюм CH & CS серии врубовая машина камень дробилка конусная дробилка чаши гильзы цилиндра

Новые поступления

Новинки товаров от производителей по оптовым ценам