Horizontal screw decanter centrifuge is a kind of spiral discharge settling centrifuge, which is pushes the slag to discharge port at the small end of the drum through the blades on the spiral pusher, and the liquid phase overflows through the overflow hole at the large end of the drum. In order to achieve the purpose of continuous separation.

This machine is horizontal spiral discharging settling centrifuge, the main machine has a column-cone bowl, spiral stoker, differential system, bearing seat, base, cover, main motor,vice motor, and electric control chamber. With the high speed rotating of bowl, form strong centrifugal force, making the dehydrate continuously in 24 hours a day.

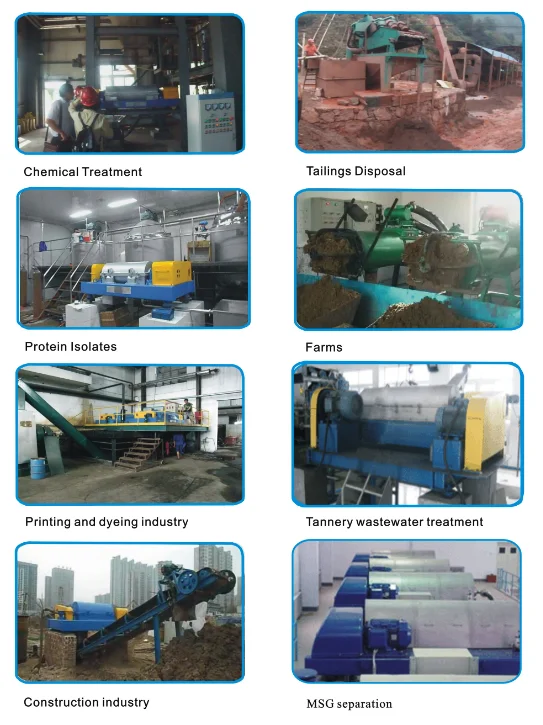

It is characterized by compact structure, continuous operation, stable operation, strong adaptability, large production capacity and convenient maintenance. It is suitable for the separation of suspension with solid particle size greater than 0.005mm and concentration range of 2-40%. Widely used in chemical, light industry, food, environmental protection and other industries.