YOGIE OEM Высокоточная бесшовная стальная труба с механической подкладкой 40 35crmo центробежная литая катушка

- Категория: >>>

- Поставщик: Luoyang Yujie Industry & Trade Co. Ltd.

Сохранить в закладки 1600854747155:

Описание и отзывы

Характеристики

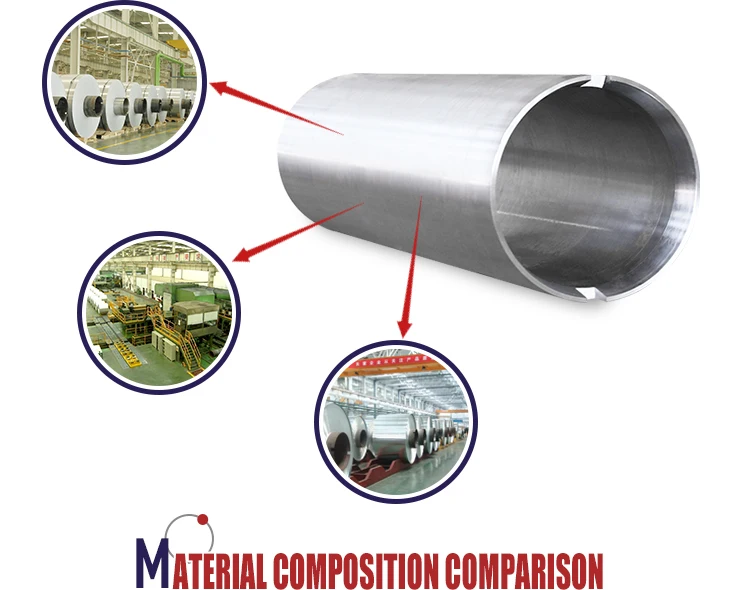

High Precision Alloy Steel Large Centrifugal Casting precision Steel Spool Sleeve aluminium winding steel spool

The quality of steel sleeve is determined by the different application and temperature. Spools, also known as winding spools or occasionally rolling mill sleeves, are thick-walled tubes used for winding thin aluminium strips, aluminium foil or stainless steel thin sheet metal for transportation in the manufacturing process and storage. The wound metal is called a coil.

It mainly used in alumina foil plant and Tin foil plant. our company offers the materials as follow:

Elements | C | Si | Mn | Cr | Ni | Mo | v | S,P | Introduction |

ZG310-570 | 0.50 | 0.6 | 0.90 | ≤0.040 | Low plasticity and toughness, low temperature resistance, low purchasing cost. | ||||

35CrMo | 0.32-0.40 | 0.17-0.37 | 0.40-0.70 | 0.80-1.10 | 0.15-0.25 | ≤0.035 | High strength, toughness and hardening, high temperature resistance, low purchasing | ||

35CrMoV | 0.30-0.38 | 0.17-0.37 | 0.40-0.70 | 1.00-1.30 | 0.20-0.30 | 0.10-0.20 | ≤0.035 | Better than 35CrMo performance, and can meet the general use requirements, low price. | |

35NiCrMo | 0.30-0.37 | 0.6-0.9 | 0.40-0.90 | 0.40-0.90 | 0.60-0.90 | 0.40-.-0.50 | ≤0.035 | High strength and toughness, high temperature resistance, high cost. | |

KCP-12 | 0.20-0.30 | ≤0.60 | 0.90-1.10 | 0.40-0.90 | 1.00-1.50 | 0.30-0.50 | ≤0.040 | High strength and toughness, high temperature resistance, high cost. |

(1) The feature of centrifugal casting is that the sleeve has a good metal feeding effect, the casting has a dense structure and good mechanical properties.

The blanks which were produced by centrifugal casting can ensure the material density of the sleeve is close to the forgings, and the internal and external surfaces do not have defects such as pores, blisters, looseness, inclusions, and cracks of the ordinary sand castings.

(2)Use the special tool to process end face, taper and the outer diameter of steel sleeve spool according to inner hole to ensure beating of the taper, the concentricity and cylindricity of the steel spool.

Material | Strength of extension(MPa) | Yield strength(MPa) | Ductility(%) |

ZG310-570 | 570 | 310 | ≥17 |

35CrMo | ≥985 | ≥835 | ≥12 |

35CrMoV | ≥1080 | ≥930 | ≥10 |

35NiCrMo | ≥830 | ≥660 | ≥8 |

KCP-12 | ≥1080 | ≥835 | ≥8 |

1. Annealing

Annealing is to heat the steel spool to the appropriate temperature and then slowly cool the steel sleeve to achieve or close to the equilibrium state.

2, Normalizing

Normalizing is making steel spool cool after it reaches suitable temperature, the effect of normalizing is similar to annealing, commonly used to improve the cutting performance of material, also sometimes used for low requirements for some parts as the final heat treatment.

3. Quenching

Quenching is the rapid cooling process in the quenching medium of water, oil or other organic salts and organic water, after the heating of work piece. The steel is hardened after quenching, but it is brittle at the same time.

4, Tempering

Tempering is in order to reduce the brittleness of steel. Place the steel which is after quenching in higher than the room temperature and under 650 ℃ for a long time of heat preservation, cooling again , this process is called tempering.

The package would be according to customer requirements, and it is coated with anti-rust oil. It would be rolled by plastic cloth and the grass ropes.

It is delivered by a whole lot, with measures of anti-collision without other goods. Besides, it also can be packaged and shipped according to export standard.

CNC gantry milling and boring machine,CNC machining center equipped with the fourth axis, CNC floor-type boring machine is equipped with the fourth axis and rotary worktable, it can realize five axis machining. The work piece is not limited by the size.It is suitable for machining large module and large size gear, boxes,and large non -standard parts.

Похожие товары

Пользовательские 3-осевые 5-осевые детали для велосипеда с ЧПУ

Литье под давлением из нержавеющей стали

Китайский поставщик, отливная часть из алюминиевого сплава

Изготовленный на заказ металлический сплав инвестиции прецизионное литье из нержавеющей стали Центробежное рабочее колесо

Литая чугунная крышка люка для маховика, центробежная металлическая инвестиционная латунь, литейная форма из восковой стали

Центробежное высоковольтное сварочное лезвие штамповки железной части

YUESHEN 225 мм EC, обратный центробежный вентилятор 2800 об./мин. По часовой стрелке, вытяжной вентилятор EC

Новые поступления

Новинки товаров от производителей по оптовым ценам