DTRO disc tube reverse osmosis membrane waste water treatment

- Категория: >>>

- Поставщик: Tianjin Justin Technology Co. Ltd.

Сохранить в закладки 1600868921849:

Описание и отзывы

Характеристики

Disc Tubu RO Membrane DTRO DTNF

Disk tubular RO/NF DTRO / DTNF

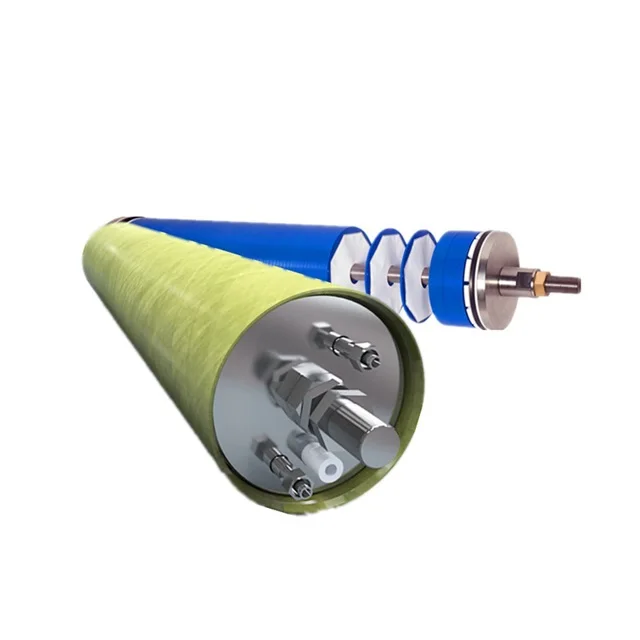

DTRO/DTNF Introduction

Disk tubular membrane technology referred to as DT, common for disk tubular RO(DTRO) and disk tubular (DTNF). The membrane module structure is distinct from the traditional spiral wound membrane.With open flow channels,feed flows through the entrance into the pressure vessel and reach the disk in a short distance. Then the feed flows 180 degrees from one side of the membrane reverse flow into the other side of the membrane,into the next disk again and finally runoff from outlet.The special design makes feed collide with the disk bulge through the membrane surface forming turbulence which increases flow rate and self-cleaning function and long service life of the membrane.

Features

High strength design, up to 120 bar operating pressure

Open disk with low flow resistance and concentration polarization

High pressure resistance and salt rejection membrane

Applications

Landfill leachate

High concentration of industrial wastewater

Spiral wound RO/NF concentrates

Industrial high salts water

DTRO/DTNF module

DTRO/DTNF Membrane

Disk

SUS center link

High pressure vessel

Inlet and outlet pipe and accessories

A typical process diagram

DTRO/DTNF Specifications

Items | High pressure | High pressure | Super high pressure |

Mode | DTRO-1 | DTNF-1 | DTRO-2 |

Membrane material | Composite Polyamide | Composite Polyamide | Composite Polyamide |

Disk qty. (pc) | 209 | 209 | 209 |

Rejection (%) | 99 | 97 | 99 |

Membrane effective area (m2) | 9.4 | 9.4 | 9.4 |

Feed flux (l/h) | 500-1200 | 500-1200 | 500-1000 |

Permeate flux range (l/h) | 8-40 | 8-40 | 8-35 |

Disk material | ABS | ABS | ABS |

Vessel materia | Fiberglass | Fiberglass | Fiberglass/SUS |

Operation pressure (bar) | 75 | 75 | 120 |

Max. TMP (bar) | 9 | 9 | 9 |

Max. operation temperature (℃) | 40 | 40 | 40 |

Chlorine tolerance (ppm) | <0.1 | <0.1 | <0.1 |

Recommended operation pH | 6-9 | 6-9 | 6-9 |

Chemical cleaning pH@40℃ | 2-11 | 2-11 | 2-11 |

Note:

Performance data above is the nominal value.

The actual permeate flux of individual module may be in ±15% range.

Test condition:

RO: NaCl 32,000mg/L@800psi.

NF: MgSO4 30,000mg/L@600psi.

DTRO High Pressure Disc Tubu RO Membrane Element

Application:

Lanfill leachate and other high TSS waste water

DTRO Membrane Element Dimensions

DTRO-1 size is 216mm, DTRO-2 size is 220mm.

DTRO Membrane Element Specifications:

Model | DTRO-1 | DTRO-2 |

Membrane type | BW type | SW type |

Membrane material | Polyamide composite | Polyamide composite |

Membrane cushion qty.(pc) | 209 | 209 |

Membrane element structure | Disc tube with GRP vessel | Disc tube with GRP vessel |

Membrane effective area | 9.4m2 (101ft2) | 9.4m2 (101ft2) |

Rejection(%) * | 98 | 99 |

Lowest rejection(%) | 95 | 98 |

Feed flow( l/h) | 500-1000 l/h | 500-1000 l/h |

Permeate flow( l/h) | 80-450 l/h | 80-350 l/h |

Disc material | ABS | ABS |

Max. feed side pressure drop: | 9bar | 9bar |

Max. feed side operation pressure | 75bar | 90bar |

Max. operating temperature: | 40℃ | 40℃ |

Allowable pH – continuous operation: | 6-9 | 6-9 |

Allowable pH – short term cleaning @40℃ range | 2-12 | 2-12 |

Free chlorine tolerance | ≤0.1ppm | ≤0.1ppm |

Water inlet and outlet connection (mm) | 12 swagelock | 12 swagelock |

Permeate connection (mm) | 9 coupling hose pipe | 9 coupling hose pipe |

Note:

Performance data above is the normal value.

The actual permeate flux of individual module may be in ±15% range.

Test conditions:

RO: NaCl 32,000.mg/L @55.2 bar.

DTRO Super High Pressure Disc Tubu RO Membrane Element

Application:

Lanfill leachate and other high TSS waste water

DTRO Membrane Element Dimensions

DTRO Membrane Element Specifications:

Model | DTRO-H1 | DTRO-H2 |

Membrane type | SW type | SW type |

Membrane material | Polyamide composite | Polyamide composite |

Membrane cushion qty.(pc) | 209 | 209 |

Membrane element structure | Disc tube with GRP vessel | Disc tube with GRP vessel |

Membrane effective area | 9.4m2 (101ft2) | 9.4m2 (101ft2) |

Rejection(%) * | 99 | 99 |

Lowest rejection(%) | 98 | 98 |

Feed flow( l/h) | 500-1000 l/h | 500-1000 l/h |

Permeate flow( l/h) | 80-350 l/h | 80-280 l/h |

Disc material | ABS | ABS |

Max. feed side pressure drop: | 9bar | 9bar |

Max. feed side operation pressure | 120bar | 160bar |

Max. operating temperature: | 40℃ | 40℃ |

Allowable pH – continuous operation: | 6-9 | 6-9 |

Allowable pH – short term cleaning @40℃ range | 2-12 | 2-12 |

Free chlorine tolerance | ≤0.1ppm | ≤0.1ppm |

Water inlet and outlet connection (mm) | 12 swagelock | 12 swagelock |

Permeate connection (mm) | 9 (hosepipe connection) | 9 (hosepipe connection) |

Note:

Performance data above is the normal value.

The actual permeate flux of individual module may be in ±15% range.

Test conditions:

RO: NaCl 32,000.mg/L @55.2 bar.

Product Show

Tianjin Justin Technology Co., Ltd. is a rising high-tech enterprise in Chinese water treatment membrane industry. The company is mainly engaged in the processing and production of various reverse osmosis(RO) membrane,flat sheet membrane bioreactor(MBR),hollow fiber membrane bioreactor(MBR),hollow fiber ultrafiltration (UF) membrane. The water treatment membrane production base was put into production in 2010.

By the establishment of strategic partnerships with well-known international water treatment membrane companies, the company has introduced advanced international production technology. The key raw materials used in the membrane come from well-known Chinese and foreign manufacturers. Every piece of membrane produced by this company has been well tested to ensure its salt rejection rate and permeate flow are above the standard requirement. After years of digestion, absorption and innovation, with the spirit of perseverance and the meticulous attitude towards the products, the performance of the company's full range of membrane product has reached the international advanced level.

“HatChee” and "SeeChee" is our brand names.

With the development of this compan, we build lost of warehouses in China. And our products is more extensive,such as:

Ceramic Membrane, MBR Membrane, UF Membrane, DTRO Membrane, Ro Membrane, SS/FRP Membrane Vessel, FRP Pressure Tank, Softener Valve, Filter Valve, Water Pump, Ion Exchange Resin, Filter Cartridge, Stainless Steel Filter, UV Sterilizer, Ozone Generator, Sewage Filling, Water Distributor, Riser Tube, Dosing Pump, Pressure Gauge, Flow Meter, Solenoid Valve, Brine Tank, Dosing Tank, etc.

The company always adheres to the business philosophy of “forging brand with technology; showing strength with innovation” and “customer-centered, market-oriented”, and serves to water treatment industry with high-quality products and complete techniques.

Why Choose Us

| |||

INDEPENDENT FACTORY

We are the source factories and have many oversized factories and our own workshops with different products. | OEM SUPPORT

We can produce the goods according to the customers’ requirements. And we can make the customers’ brand. | PRODUCT UPDATE

We have our own R&D team to update the products. Some products have applied for a patent for the appearance. | QUALITY ASSURANCE

We strictly produce goods according to ISO, NSF, CE, ASME certification. All products must be qualified before sold. |

| |||

FAMOUS BRAND

Cooperate with most of the famous brands in water treatment industry.

| GOOD PACKAGING

In order to protect the goods,most of the goods are with quality cartons or wooden boxes. | PROFESSIONAL TEAM

Sales,engineers and after-sales teams offer the 24-hour online service for each customers. | SATISFIED SERVICE

We build a large water treatment products system. Customers can get satisfied from us. |

Q: Are you a trading company or a manufacturer?

A: We are one of China leading water treatment membrane manufacturers since 2010, with our OWN auto making line!

Q: Where is your factory? How can I visit?

A: We have more than three factories in different cities. They located in Tianjin city, Nantong City of Jiangsu Province...etc. You can visit our Tianjin head office. Then we will take you to our factories.

Q: What's your brand name?

A: Our brands is named "HatChee" and "SeeChee".

Q: Can we OEM from your factory?

A: Yes. Normally, we export under our brand name HatChee or SeeChee. If you have any request, we also provide OEM, ODM service.

Q: Can I get some samples? Can I place small order before bulk purchase?

A: We're glad to provide sample, trial order welcome for first time, please kindly contact us.

Q: How can I place order? How can I pay you?

A: You can contact us by email about your order details, or place order on line. After you confirm our PI, we will request you to pay. T/T (Citibank) and Alipay, Western Union are the most usual ways we are using.

Q: How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock. Or it is 7-15 days if goods are not in stock, it is according to quantity.

Q: What is your working time?

A: We offer the 24-hour online service for each customers.

Похожие товары

2022 серьги из нержавеющей стали

Частная Марка, расслабляющая веганская Лавандовая ложка, Органическая травяная скраб, соли для ванн с

Электронный компонент MQ-4 природного газа Модуль датчика метана MQ газа

Прямая продажа с фабрики, новая пляжная сумка через плечо, наклонная Плетеная соломенная сумка ручной работы

Черные чернила для струйной печати CN55 500 мл бутылка

Высокое качество, 600 мл, ручная упаковка для колбасы, герметик с иглой

4,8/8,8/10,9/12,9 класс Высокое качество винт с крыльчатой гайкой M2 Din315 крыльчатые гайки из углеродистой стали бабочка

Новые поступления

Новинки товаров от производителей по оптовым ценам