Полностью автоматическое оборудование для порошкового покрытия окон алюминиевых профилей

- Категория: >>>

- Поставщик: Hebei Hanna Technology Co. Ltd.

Сохранить в закладки 1600886651902:

Описание и отзывы

Характеристики

Product Type

Our mainly products include: Manual powder coating machine, Automatic powder coating line, Spray painting equipment, Pretreatment System, Drying Oven, Powder Spraying Gun, Reciprocator, Fast Automatic Color Change Equipment, Powder Coating Booth, Powder Recovery Equipment, Conveyor Chains, Curing Oven, etc.

All the systems are widely used on the applications of automotive, home and office appliance, machines industry, metal fabrications and so on.And through to CE, ISO 9001 standards.

*Pollution free operation*Safe to operate

*Maximum recovery efficiency

*Durability

*Quick color change

*Maximum recovery efficiency

*Durability

*Quick color change

Products Feature

Automatic Spraying Pretreatment

1 . Pre-Degreasing - Degreasing(Hot Water Washing) - Surface Conditioning - Phosphating/Silane/Chromizing - Rinsing-Rinsing -Drying .

2. According Different Processes Custom the Pretreatment Equipment System .

3. Such As Shot Blasting ,Sand Blasting ,Etc.

2. According Different Processes Custom the Pretreatment Equipment System .

3. Such As Shot Blasting ,Sand Blasting ,Etc.

Dipping Tanks Pretreatment

1, Different Workpieces use Different Pretreatment Method .

2, Powder Coating Quality Depend On The Pretreatment Cleaning Quality.

3, HANNA Offer The Most Reasonable and Economical Solution .

2, Powder Coating Quality Depend On The Pretreatment Cleaning Quality.

3, HANNA Offer The Most Reasonable and Economical Solution .

Powder Coating Booth System

1. No Dust Spillover ,Saving Powder .2. Quick Color Changing (10-15mins Automatic Color Changing ),Multi -Color Changing .

3. Powder Recovery Rate As High As 99.2% .

4. The Workpiece Groove Had No Bottoming Phenomenon.

5. Full Consider The Need of Color Change ,Easy to Clean ,Save Time ,Improve Work Efficiency

3. Powder Recovery Rate As High As 99.2% .

4. The Workpiece Groove Had No Bottoming Phenomenon.

5. Full Consider The Need of Color Change ,Easy to Clean ,Save Time ,Improve Work Efficiency

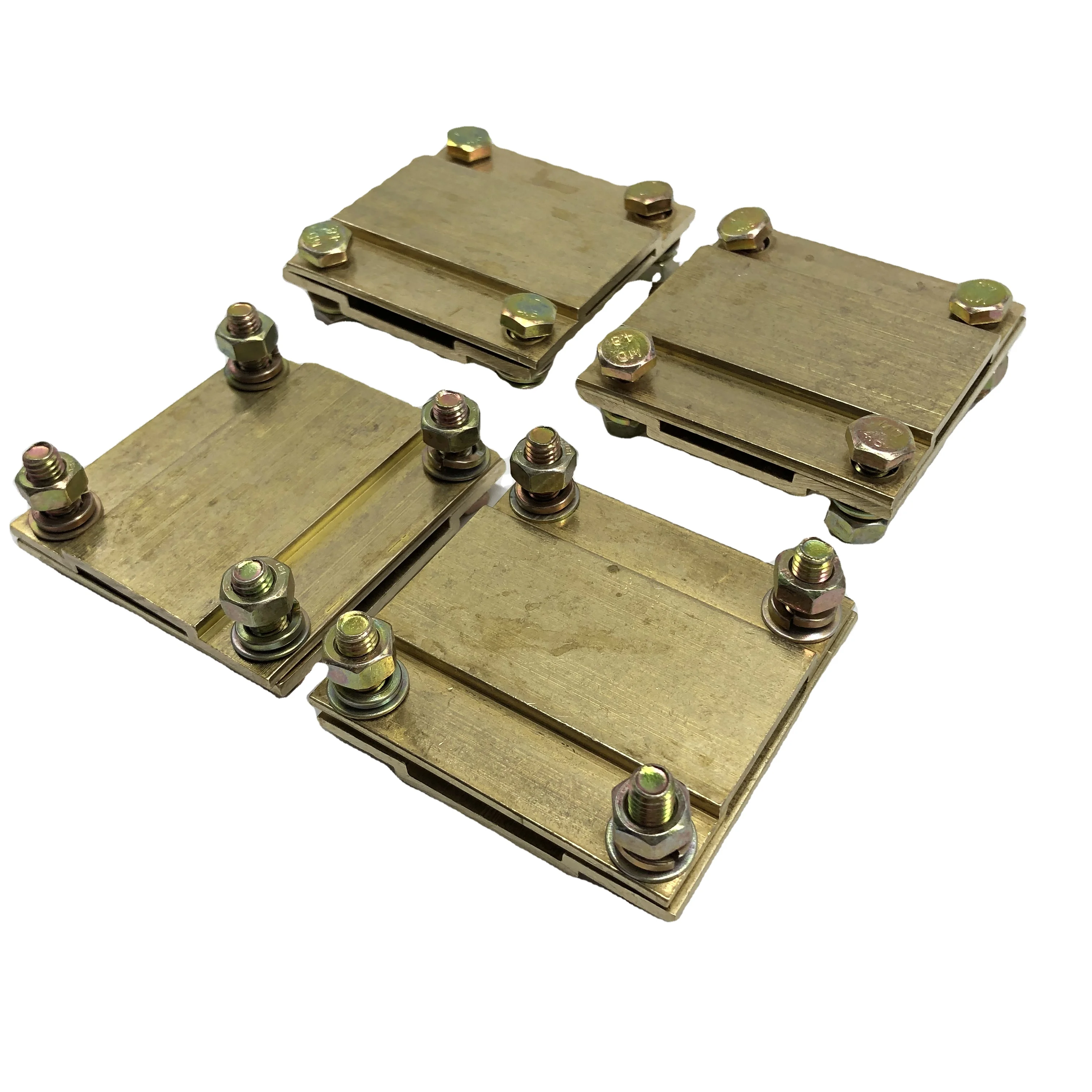

Conveyor System

Light Chain : Heavy Chain :

* QXG150 ≤ 30KG * XT80 ≤ 125KG

* QXG250 ≤ 50KG * XT100 ≤ 500KG

* QXG300 ≤ 80KG * XT160 ≤ 800KG

1. Based on Customer Needs ,Provide The Corresponding Optimal Design

2. Fine Workmanship to Ensure Operational Stability

3. Highly Automated Process to Increase Efficiency

* QXG150 ≤ 30KG * XT80 ≤ 125KG

* QXG250 ≤ 50KG * XT100 ≤ 500KG

* QXG300 ≤ 80KG * XT160 ≤ 800KG

1. Based on Customer Needs ,Provide The Corresponding Optimal Design

2. Fine Workmanship to Ensure Operational Stability

3. Highly Automated Process to Increase Efficiency

Bridge Type Curing Oven

This Oven Has A Good Thermal Insulation Effect ,Because Of The Hot Air Is on A High Level And will Not Convection With Cold Air Outside The Oven .

HANNA Hot Air Circulation Oven Furnace Has Good Heat Preservation ,Uniform Temperature in The Oven Furnace Andess Heat Loss .

After Testing ,The Temperature Difference in The Oven is Less Than ± 3℃

HANNA Hot Air Circulation Oven Furnace Has Good Heat Preservation ,Uniform Temperature in The Oven Furnace Andess Heat Loss .

After Testing ,The Temperature Difference in The Oven is Less Than ± 3℃

HANNA Curing Oven Features

1. Has Air Curtain At The Both Ends , The Hot Air In The Oven Won't Dissipate To Outside,Saving The Fuel .Patent Product

2. Curing Oven Insulation Board Are All Plug-In Board ,Seamless Docking ,Thermal Bridge Transmission Technology ,Saving Fuel .

3. Hot Air Circulation Air Supply And Return Reach A Balance ,Reasonable Layout ,Uniform Oven Temperature .

After Testing ,the Temperature Difference In the Oven is Less Than ± 3 ℃ ,Reaching the Performance Index of The Similar Products Of The Advanced Countries

2. Curing Oven Insulation Board Are All Plug-In Board ,Seamless Docking ,Thermal Bridge Transmission Technology ,Saving Fuel .

3. Hot Air Circulation Air Supply And Return Reach A Balance ,Reasonable Layout ,Uniform Oven Temperature .

After Testing ,the Temperature Difference In the Oven is Less Than ± 3 ℃ ,Reaching the Performance Index of The Similar Products Of The Advanced Countries

Products Application

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Why Choose Us

OUR ADVANTAGE:Pollution free operation,Safe to operate,Maximum recovery efficiency,Durability,Quick colour change.

Professional Design ,Professional Scheme ,Professional Installation.

1,Hanna intelligent gun, unique circuit board design, Complete solve the

problem of workpiece powder grooves on the dead angle, groove with powder.

2,Hanna unique to the wind system which make the

effective temperature difference control furnace temperature fluctuate 3 ℃, ensure that products without color difference,coating dose not fall off.

Professional Design ,Professional Scheme ,Professional Installation.

1,Hanna intelligent gun, unique circuit board design, Complete solve the

problem of workpiece powder grooves on the dead angle, groove with powder.

2,Hanna unique to the wind system which make the

effective temperature difference control furnace temperature fluctuate 3 ℃, ensure that products without color difference,coating dose not fall off.

3,Hanna big cyclone recovery system powder recovery rate as high as 99.2%,ensure no dust spillover.Unique fast

color change powder supply center, change color only 10 to 15 minutes.

color change powder supply center, change color only 10 to 15 minutes.

Equipment | Application |

Pre-treatment System | Better powder coating of the work-piece. Dip tank pretreatment Spraying pretreatment |

Powder Coating system fast color change | Big cyclone + secondary filter recovery Simple filter recovery |

Conveyor Transport System | Manual conveyor Fully automatic conveyor system |

Curing Oven | It makes the powder attaching to the work-piece. Tunnel oven, bridge oven, box oven . |

Service assurance:

1,Provide complete information, including equipment drawing, electrical circuit control chart and use maintenance instruction.

2,Equipment troubleshooting method.

3,Provide the list of consumables to assist customers in establishing a comprehensive equipment maintenance system.

4,After the equipment is delivered to the customer, our company will send professionals to track the customer equipment for 60 days.

5,If customer has a device failure in the process of using the device, our company will operate the device

remotely through the computer network through the authorization given by the customer, and eliminate all equipment failure problems.

6,Any problems with the equipment, our company guarantees to give solutions within 12 hours.

7,The warranty period of the equipment is 2 years. In 2 years, spare parts will be provided free of charge for any problems caused by non-human factors

2,Equipment troubleshooting method.

3,Provide the list of consumables to assist customers in establishing a comprehensive equipment maintenance system.

4,After the equipment is delivered to the customer, our company will send professionals to track the customer equipment for 60 days.

5,If customer has a device failure in the process of using the device, our company will operate the device

remotely through the computer network through the authorization given by the customer, and eliminate all equipment failure problems.

6,Any problems with the equipment, our company guarantees to give solutions within 12 hours.

7,The warranty period of the equipment is 2 years. In 2 years, spare parts will be provided free of charge for any problems caused by non-human factors

Company Introduction

Since 1990,From simple manual spraying to automatic powder spraying system.

We can provide you with innovative, rational and economical solutions.

We can support you with advanced technologies.Delivering the best powder coating equipments and turn-key solutions. We’ve built thousands of optimal customized lines and systems for powder coating operations across China and around the world.

Our continuous research on the field as well as our constantly developing techniques and innovative nature of our engineering dpt. enable our customers to catch up to the latest developments by modernizing their equipment partly or wholly, so as to improve performance, increase profits and maintain their competitiveness in the world of trade.

Our company has passed ISO9001 certification,CE certification, and has obtained more than 70 patents.

Customer Visit

Ordering Process

FAQ

We are manufacturer and exporter. Our own factory was found in 1990,Our export office was established in 2014.

What should I provide if interested in your powder coating equipment ?

A.The material/size(max)/weight(max)of your workpieces.

B.How many of your daily output(one day=8 hours,one month=30 days)?

C.What heating power do you prefer: electric,gas, diesel or coal?

D.The size of your factory(length, width and height)?

How to ensure the quality of the equipment ?

A,We have hundreds of patents and passed the IS9001: 2015 quality management system certification.

B,The Technical Review Committee,reasonably determines and divides the stages of design, production, installation and

commissioning, and formulates detailed progress plans for each stage, Strengthen the quality assurance system and quality protection measures of equipment manufacturing department.

C,We manning quality inspectors specially to control the processing quality of product strictly.

How to install equipment after purchasing your equipment ?

A,We will provide installation information and installation videos.

B,Our engineers will guide the installation and run the equipment.

C,After the debugging, will provide complete training and track customer device usage.

A,We will provide installation information and installation videos.

B,Our engineers will guide the installation and run the equipment.

C,After the debugging, will provide complete training and track customer device usage.

How is your company's after-sales service done?

A,Provide the list of consumables to assist customers in establishing a comprehensive equipment maintenance system.

B,After the equipment is delivered to the customer, our company will send professionals to track the customer equipment for 60 days.

C,If customer has a device failure in the process of using the device, our company will operate the device remotely through the computer network through the authorization given by the customer, and eliminate all equipment failure problems.

D,Any problems with the equipment, our company guarantees to give solutions within 12 hours.

Похожие товары

Гарантия качества, длинная Полезная трава, искусственная ковровая трава

3,90 $ - 4,50 $

Швабра DEKO Magic Mop с ведром, Бытовая Автоматическая вращающаяся швабра с ведром для уборки деревянного пола, прокладки из микрофибры, товары для дома

9,60 $ - 9,80 $

Электрический фланцевый нагревательный элемент 220-240 В X-образные аксессуары от

3,73 $ - 4,82 $

N0795YN180 westcode scr Тиристор в наличии

17,45 $ - 34,90 $

Электронные наушники-вкладыши

Мешалка для кофе из березовой древесины 1000 шт. в

11,40 $

3*25 медный кабельный провод Лента заземление резьбовой стержень седло латунный

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $