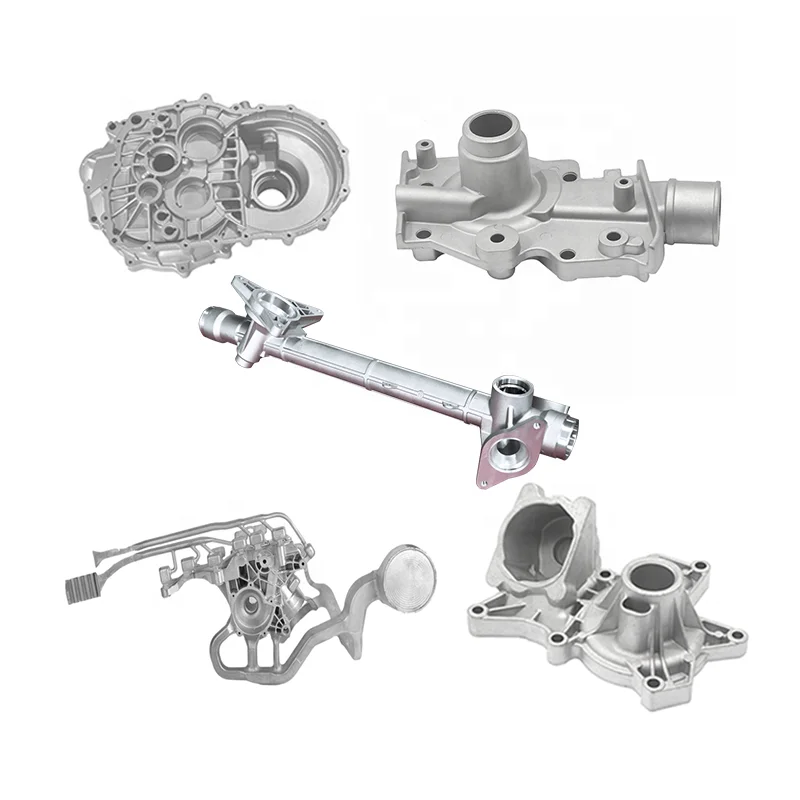

Индивидуальные услуги китайского профессионального производства OEM небольшой алюминиевый литой

- Категория: >>>

- Поставщик: Dongguan Winner Manufacture LimitedDongguan Limited

Сохранить в закладки 1600893024887:

Описание и отзывы

Характеристики

Our Service

Tooth Profile | Spur Gears, Helical Gears, Bevel Gears |

Module | M0.5, M0.8, M1.0, M1.5,M2.0,M2.5,M3.0...etc |

Teeth Quantity | 10-150 teeth or customized |

Inner Bore | 2-200mm or customized |

Pressure Angle | 20 Degree |

Direction | Left hand or right hand |

Teeth Width | Customized |

Total Thickness | Customized |

Heat Treatment | Gear Teeth Induction Quenching |

Application Industry | ||

Automotive | Power Steering Rack and Pinion Assembly Steering Gear Rack and Pinion Unit Steering Rack and Pinion Kit Rack and Pinion Steering Gear Box | |

Industrial Machinery | Linear Motion Rack and Pinion System Rotary Motion Rack and Pinion Drive Actuator Rack and Pinion Assembly Positioning System with Rack and Pinion | |

Material Handling | Crane Hoist Rack and Pinion System Scissor Lift Rack and Pinion Drive Cargo Elevator Rack and Pinion Assembly Automated Storage and Retrieval System (ASRS) Rack and Pinion Drive | |

Construction | Scaffolding Rack and Pinion System Elevator Rack and Pinion Drive Bridge Formwork Rack and Pinion Assembly Mast Climbing Work Platform Rack and Pinion Drive | |

Robotics | Robotic Arm Rack and Pinion Drive Linear Actuator with Rack and Pinion System CNC Machine Tool Rack and Pinion Drive Gantry Robot Rack and Pinion Assembly | |

Product Display

Common Material

Metals: Metals like aluminum, brass, copper, stainless steel, and titanium are popular choices for CNC machining. They are durable, have high tensile strength, and can be easily machined to produce complex parts.

Plastics: CNC machining can work with many types of plastics, including ABS, acrylic, nylon, PEEK, polycarbonate, and PVC. These materials are lightweight, cost-effective, and have good chemical and impact resistance.

Composites: Composite materials such as carbon fiber, fiberglass, and Kevlar are used in many industries, including aerospace,automotive, and sports equipment. CNC machining can create complex shapes and patterns with these materials.

Foam: CNC machining can also work with foam materials, such as polystyrene and polyurethane. These materials are commonly used in packaging, insulation, and model-making.

Ceramics: CNC machining can produce intricate ceramic parts for medical, aerospace, and electronic applications. Ceramic materials have high strength, high temperature resistance, and good electrical insulation properties.

Metals: Metals like aluminum, brass, copper, stainless steel, and titanium are popular choices for CNC machining. They are durable, have high tensile strength, and can be easily machined to produce complex parts.

Plastics: CNC machining can work with many types of plastics, including ABS, acrylic, nylon, PEEK, polycarbonate, and PVC. These materials are lightweight, cost-effective, and have good chemical and impact resistance.

Composites: Composite materials such as carbon fiber, fiberglass, and Kevlar are used in many industries, including aerospace,automotive, and sports equipment. CNC machining can create complex shapes and patterns with these materials.

Foam: CNC machining can also work with foam materials, such as polystyrene and polyurethane. These materials are commonly used in packaging, insulation, and model-making.

Ceramics: CNC machining can produce intricate ceramic parts for medical, aerospace, and electronic applications. Ceramic materials have high strength, high temperature resistance, and good electrical insulation properties.

Application Field

Our Factory

Dongguan Winner Manufacture Ltd is a comprehensive technical service enterprise that integrates precision hardware design, development, manufacturing, and sales. The existing factory covers an area of over 4000 square meters. The company has convenient transportation, beautiful environment, complete factory facilities and excellent machinery and equipment, as well as a group of professional and high-quality management teams. With strong scientific research and technical strength, long-term processing and manufacturing experience, and reliable after-sales service, it has won good customer relationships and has become an excellent supplier of well-known brands and enterprises at home and abroad. The company has CNC machining centers, CNC lathe departments, automatic lathe departments, and mature post processing processes such as laser engraving, oxidation, sandblasting, and high gloss. The company currently has over 100 precision equipment such as CNC computer lathes, precision automatic lathes, precision carving machines, laser carving machines, sandblasting machines, grinding machines, etc. To ensure product quality, we are equipped with testing equipment such as 3D, 2.5D, projector, salt spray testing machine, high-temperature and high humidity machine, film thickness tester, roughness tester, tensile tester, hardness tester, height gauge, etc

Customer Review

FAQ

1. What is the load capacity of the custom rack and pinion system?

The load capacity of the custom rack and pinion system is dependent on several factors, including the size and material of the rack and pinion components, the gear ratio, and the application requirements. We can work with you to determine the load capacity needed for your specific application and design a custom solution that meets those requirements.

2. What is the speed of the custom rack and pinion system?

The speed of the custom rack and pinion system is dependent on the gear ratio selected. We can work with you to determine the required speed for your application and select an appropriate gear ratio to achieve that speed.

3. What is the precision of the custom rack and pinion system?

The precision of the custom rack and pinion system is dependent on several factors, including the gear ratio, the size and material of the rack and pinion components, and the manufacturing process used. We can work with you to determine the precision requirements of your application and design a custom solution that meets those requirements.

4. What are the dimensions of the custom rack and pinion system?

The dimensions of the custom rack and pinion system will be determined by the application requirements. We can work with you to determine the necessary dimensions for your application and design a custom solution that meets those requirements.

5.What lubrication method and frequency should be used for the custom rack and pinion system?

The lubrication method and frequency for the custom rack and pinion system will depend on several factors, including the application requirements, the materials used for the rack and pinion components, and the operating environment.

We can work with you to determine the most appropriate lubrication method and frequency for your application.

6. What materials and coatings should be used for the custom rack and pinion system to withstand the environmental factors of the application?

The materials and coatings used for the custom rack and pinion system will depend on the specific environmental factors of the application, such as temperature, humidity, and corrosive substances. We can work with you to determine the most appropriate materials and coatings to ensure the system can withstand the operating environment.

Contact Us

Похожие товары

OEM изготовленный на заказ прецизионный алюминиевый литой лучший дизайн лучшее качество

Китай профессиональный OEM высокоточный по индивидуальному заказу изделия для литья под давлением из цинкового сплава

83,03-118,61 ₽

Литье под давлением прецизионное литье по производству воска индивидуальному заказу из цинкового сплава алюминия нержавеющей стали инвестиционное

106,75-142,34 ₽

Китайская фабрика изготовленная на заказ Высокоточное Литье под давлением по выгодным ценам

1 186,09-1 541,92 ₽

Различные литые изделия из сплава под давлением на заказ

83,03 ₽

OEM завод ISO 9001 услуги литья под давлением металла Профессиональный изготовленный на заказ продукт из нержавеющей стали

59,31-142,34 ₽

Высококачественная литейная форма для литья под давлением алюминиевый литой автомобильный блок услуги по отливке товаров

474,44-593,05 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $