3d печать титановый порошок нержавеющая полированная печатная машина

- Категория: >>>

- Поставщик: Guangdong Fohan Technology Co. Ltd.

Сохранить в закладки 1600913305994:

Описание и отзывы

Характеристики

How Automotive Industrial Benefit from 3D Printing Technology

The automotive industry can benefit from 3D printing technology in a number of ways, including:

Rapid prototyping: 3D printing allows designers to quickly create physical prototypes of new automotive parts and components, reducing the time and cost associated with traditional prototyping methods.

Customization and personalization: 3D printing enables the production of highly customized parts and components, allowing car manufacturers to offer more personalized vehicles to their customers.

Improved supply chain efficiency: 3D printing can help car manufacturers reduce their reliance on traditional supply chains by enabling them to produce parts and components on-site, reducing the need for inventory and transportation.

Lightweighting: 3D printing can be used to produce lightweight parts and components, which can help improve fuel efficiency and reduce emissions.

Reduced waste: 3D printing can help car manufacturers reduce waste by producing parts and components only when they are needed, eliminating the need for large inventories and reducing the amount of scrap produced during the manufacturing process.

Innovation: 3D printing allows car manufacturers to experiment with new designs and materials, opening up new possibilities for innovation in the automotive industry.

Overall, 3D printing technology can help the automotive industry become more efficient, flexible, and innovative, while also reducing costs and improving the overall quality of vehicles.

Greatly Improve Automotive Manufacturing

3D print steering knuckle slm selective laser melting metal. The steering joint structure is designed by lightweight design, and the force transmission path of each interface is effectively extracted. The weight of the overall structure is reduced by 33%. The optimized results are formed by 3D printing, which effectively avoids the mold filling difficulties and metallurgical defects of castings brought by traditional casting process. Others advantages like, shortern R&D cycle, reduce cost, verify structure and appearance etc.

3D Printing Innovation The New Energy Vehicles

Use new PET-GF material make the battery case for new energy vehicles faster and enhance the performance, lighter the weight. 3D printing allows for the creation of parts with complex geometries that are difficult or impossible to produce using traditional manufacturing methods. This can result in improved performance, such as reducing weight and increasing strength.

3D Printing Make Vehicle Modifications Easier

3D printing allows for the creation of unique and custom-designed parts that can be tailored to specific vehicle modifications.

This means that vehicle owners can create parts that fit their exact specifications, without having to rely on mass-produced

parts. Also time-saving and cost-saving. Every one can have their personal design cars.

This means that vehicle owners can create parts that fit their exact specifications, without having to rely on mass-produced

parts. Also time-saving and cost-saving. Every one can have their personal design cars.

Lightweight for Automobile Cliper

Automobile caliper is a kind of caliper devicewith the functions of slowing down, stoppingor keeping the moving wheels in a stopped state.

lt is generally only used for the disc brake systemlt is a part that protrudes from the outside of the brakepad and can enhance the braking performance.

lt is generally only used for the disc brake systemlt is a part that protrudes from the outside of the brakepad and can enhance the braking performance.

We Have 17 Sets BLT Metal Printers

SLM: Selective laser melting is a major technical approach in the manufacturing of metal material additives.

This technology uses laser as the energy source, and scans the metal powder bed layer by layer according to the path planned in the 3D CAD slice model. The scanned metal powder is melted and solidified to achieve the effect of metallurgical combination, and finally the metal parts designed by the model are obtained.

SLM technology overcomes the difficulties of traditional technology in manufacturing metal parts with complex shapes. It can directly form nearly fully dense metal parts with good mechanical properties.

3D Printing Technologies | SLM | ||||||

Layer thickness | ±0.1mm | ||||||

Minimum Wall Thickness | 0.50mm | ||||||

Max Printed Size | 250*250*300mm | ||||||

Accuracy | ±0.2mm | ||||||

Material | BLT Metal Powder: 316L, AlSi10Mg, TC4, Die Steel(Tool Steel) | ||||||

Leading | 1-5 Days | ||||||

After each layer, powder is distributed on top of the bed and the process repeats until the part is complete. This highly efficient method can build functional, geometrically complex parts 80 micron layers at a time - with mechanical properties that rival injection molded parts.

Based on the theory of “discrete-collecting”, metal additive manufacturing (metal 3D printing) is able to realize “dimension-reduction” manufacturing of complex 3D geometry structure. It opens up a new direction for the realization of complex structure and makes design much easier and freer. Metal AM is continuously empowered by product structure optimization design to help product designers and industry users explore more extreme possibilities and make manufacturing easier.

We Have 15 Sets HP MJF Printers

Multi Jet Fusion MJF known as HP 3D printing, is an industrial 3D printing process that produces functional nylon prototypes and

end-use production parts in as fast as 1 day. Multi Jet Fusion uses an inkjet array to selectively apply fusing and detailing

agents across a bed of nylon powder, which are then fused by heating elements into a solid layer.

end-use production parts in as fast as 1 day. Multi Jet Fusion uses an inkjet array to selectively apply fusing and detailing

agents across a bed of nylon powder, which are then fused by heating elements into a solid layer.

POST PROCESSING

We offer one-stop post-processing services

Wire-electrode cutting

In the SLM process, the metal melts and solidifies instantaneously (the cooling rate is about 10000K / s), the temperature gradient is large, resulting in great residual stress. If the substrate is not rigid enough, the substrate will be deformed. Therefore, the substrate must be rigid enough to resist the influence of residual stress.

This is using the wire-electrode cutting to depart the projects from the base board.

Polish

The surface smoothness of 3D printed parts is worse than CNC machining, casting, die casting and other processes. The main reason is that some supports generated during the printing process will leave some marks on the surface after removing the supports. This is the disadvantage of 3D printing, but in many cases, it can be achieved by manual polishing. Some products with relatively large size are welded and spliced by electric welding, and need polishing at the welding position.

Heat Treatment

Metal 3D printed parts usually need to undergo heat treatment after manufacturing. It reduces the internal stress formed in the manufacturing process and can change the microstructure of parts.

This change in microstructure will change some properties, such as toughness and hardness. Among them, one method to completely densify 3D printing metal parts to reduce porosity is hot isostatic pressing (HIP) treatment.

CNC Machining

CNC is also a good rapid prototyping process, but it can not process parts with complex shapes. CNC can also be used as a post-processing method to assist 3D printing process to achieve higher accuracy. The combination of the two processes solves the problems of complex structures and precision.

Painting

In surface treatment painting, the surface of the material is coated with a layer of paint to provide protection, improve appearance, or enhance performance. The process involves several steps, including surface preparation, application of paint, and curing. Surface preparation is a crucial step in surface treatment painting.

The surface of the material must be clean, dry, and free of contaminants such as dirt, oil, and rust. The surface may also be treated with a primer or undercoat to improve adhesion and promote a smooth finish.

Once the surface is prepared, the paint is applied using various techniques, including brushing, rolling, spraying, or dipping. The type of paint used depends on the desired effect and the material being painted. For example, automotive paint is designed to withstand extreme temperatures and weather conditions, while decorative paint is used to improve the appearance of walls and furniture.

After the paint is applied, it must be cured to achieve the desired result. Curing is the process of allowing the paint to dry and harden, which may take several hours or days depending on the type of paint and the conditions in which it is applied.

In conclusion, surface treatment painting is a popular technique used to improve the appearance and performance of materials. The process involves preparing the surface, applying the paint, and curing it to achieve the desired result.

Once the surface is prepared, the paint is applied using various techniques, including brushing, rolling, spraying, or dipping. The type of paint used depends on the desired effect and the material being painted. For example, automotive paint is designed to withstand extreme temperatures and weather conditions, while decorative paint is used to improve the appearance of walls and furniture.

After the paint is applied, it must be cured to achieve the desired result. Curing is the process of allowing the paint to dry and harden, which may take several hours or days depending on the type of paint and the conditions in which it is applied.

In conclusion, surface treatment painting is a popular technique used to improve the appearance and performance of materials. The process involves preparing the surface, applying the paint, and curing it to achieve the desired result.

Electroplating

Painting and plating are other options for coating Multi Jet Fusion parts. Performing surface smoothing first will help achieve the best results with the least additional effort. Because every industry has its own painting specifications, the best bet is to have samples done with existing painting suppliers. Hydrographs are another method of coating. An image or pattern is floated on water, the part is dipped in it to transfer the pattern over.

Given that a layer of material is applied in the process, hydrographs also result in a smoother surface.Electroplating consists of dissolving a metal in a solution and attaching the metal particles to the surface of the printed part using an electric current. Before this process can be performed on a polyamide part, the part must be made electrically conductive through the use of electroless plating, gas activation, or a conductive coating.

Mteal 3D printing Technology already widely applicated in many industrials like Aerospace, Automative, Medical, Tooling, Decoration, Fashion etc.

Mass Production 3D printed articulated dragon

This famous articulated flexi dragon was designed by Spanish designer Mcgybier, 3D printing can directly print any model with hinge structure. Fohan has 20+sets of industrial metal 3D printers offer fast manufacturing low volum integrated structural parts.

Metal Printing Service For Cunsumer Products

People's consumption standards are higher and higher these days, Pursue more personalized product appearance, and the fashion changing rapidly, all of these requires more on product designing and manufacturing. The traditional process has been unable to meet these personalized requirements of consumers. For example, such a hollow structure cannot be made by traditional CNC. At present, more and more 3D printing materials have been developed with better and better performance, which can fully meet the physical performance requirements of daily consumer goods

Tool Steel Apply in Tooling Making Field

Generally, Tooling mould is produced in small batches and have complex shapes. In particular, the manufacturing of conformal cooling water path cannot be completed by traditional CNC. 3D printing is very suitable, which not only shortens the delivery time, but also greatly reduces the cost

FQA

A: We are the biggest 3D printing manufacturer in China with 20 years experience and have over 800 sets industrial SLA printers.

Q: How long is your lead time?

A: 1. 3D drawings: about 5-7 days, it depends on the complex of your products.

2. 3D printing: about 1-3 days, it depends on the sizes of your prototypes.

3. Polishing/surface

treatments: about 1-3 days, it depends on your requests on surface treatment.

treatments: about 1-3 days, it depends on your requests on surface treatment.

4. Functional making: about 2-5 days, it depends what kinds of function you need.

5. Painting: about 2-4 days, it depends on the qty of prototypes.

6. Delivery time: about 4-5days

Q: What are files you need for quote?

A: 1. It's better to offer 3D files, like STP, STL, IGS, PARASOLID, etc.

2. 2D file isalso ok with detail requests.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but the freight be paid by customer

Похожие товары

Горячая Распродажа, Китай, высокоточные пластиковые и Углеродистые стальные литья для мебельных фитингов

В продаже в наличии в большом количестве plc реле Мицубиси FX3U-64MR-ES-A

252,30 $ - 253,10 $

Прямая продажа с завода, кузнечный молоток, низкая цена, пневматическое Кованое оборудование для металла

2 500,00 $

Чисто белая Мерцающая настенная панель в прозрачную сетку для украшения дня рождения и свадьбы невесты

0,60 $ - 0,95 $

E код мужской LVDS кабель 4 Pin HSD разъем для телематических сигналов

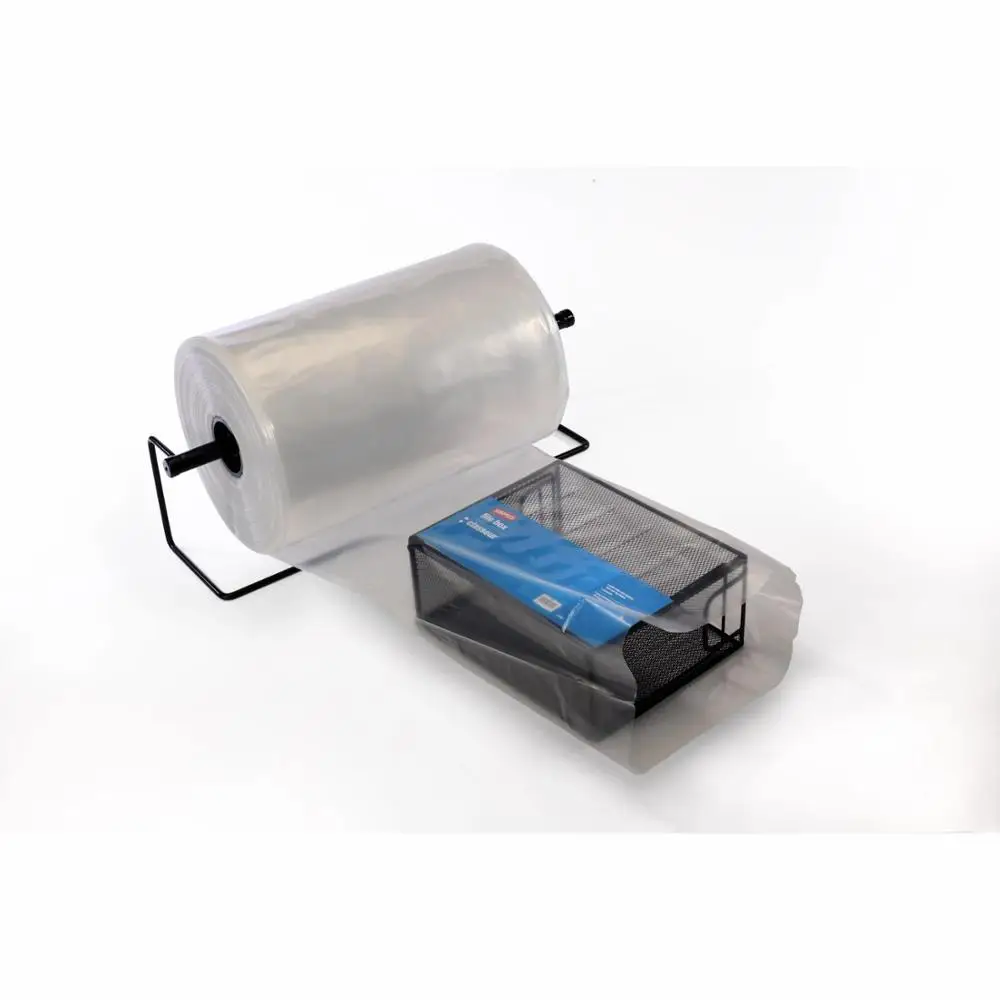

Китайская фабрика оптовая продажа прозрачная пластиковая труба низкой плотности и рулон

1,90 $ - 2,00 $

Солнечная PTZ-камера Ubox 4G, Wi-Fi 2 МП 4 МП, Солнечная камера видеонаблюдения с SIM-картой, аккумулятором, беспроводная уличная система безопасности на солнечной батарее

51,33 $ - 54,42 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $