1000 для палестинской глазурованной черепицы рулонная машина

- Категория: >>>

- Поставщик: Tianjin Ironstar Industry Co. Ltd.Tianjin Ltd.

Сохранить в закладки 1600916854882:

Описание и отзывы

Характеристики

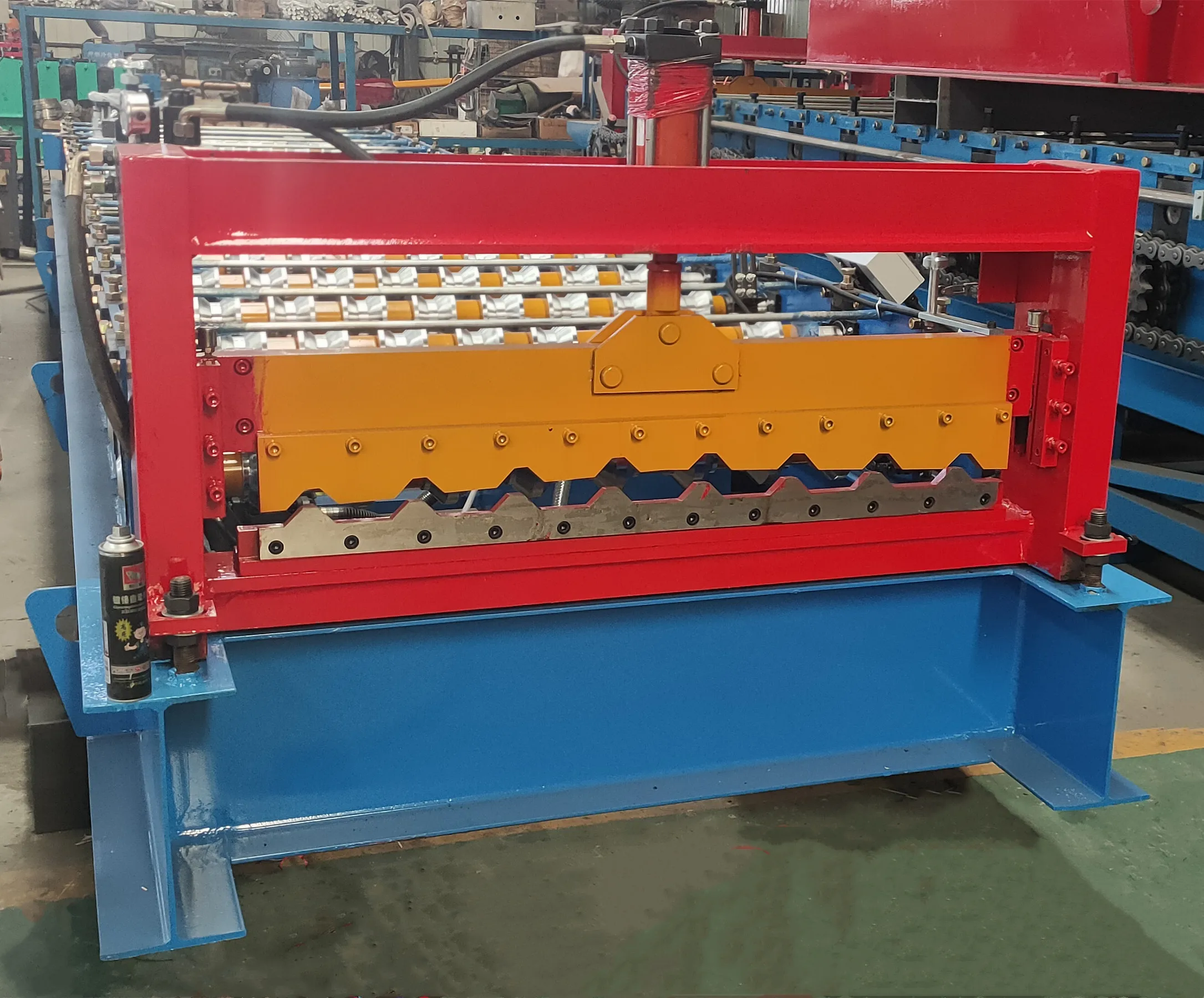

840 roofing sheet roll forming machine | metal roof roll forming machine | metal roof machine | trapezoidal sheet roll forming machine | roofing sheet making machine | wall sheet roll forming machine 1000 trapezoidal roofing sheet panel roll forming machine for Palestine 1000 for Palestine Glazed Tile Roof Panel Roll Forming Machine roofing machine

840 trapezoidal sheet roll forming machine popular sell in many countries, Coil width before rolling is 1000mm /1200mm / 1250mm. After rolling product width is 840mm, Material common is PPGI material, material thickness common between 0.3-0.8 mm. Machine details is like up type:

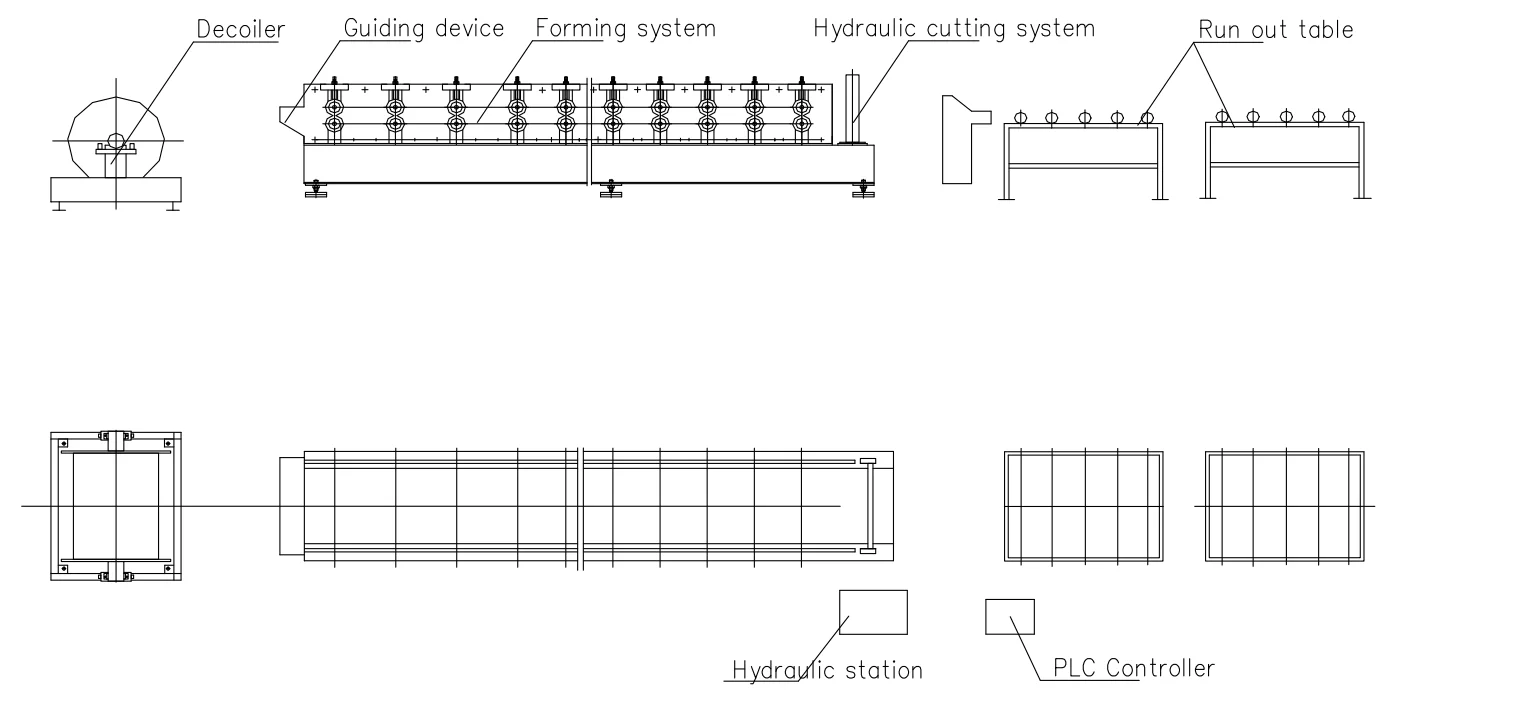

Working flow of 1000 trapezoidal roofing sheet panel roll forming machine for Palestine

Decoiler-roll forming machine-PLC control box-hydraulic cutter-Run out table

| Part details | Item Name | Specification |

| Material | Raw material | Galvanized steel or PPGI |

| Thickness | 0.3-0.8 mm | |

| Machine | Roller station | 13 |

| Shaft diameter | 70 mm | |

| Shaft material | 45# steel with 0.05mm chrome | |

| Roller material hardness 30-40 HRC | 45# steel with 0.05mm chrome | |

| Machine size | About 6.2×1.5×1.3 m | |

| Machine weight | About 3.5 ton | |

| Machine color | As customer' request | |

| Working speed | 8-20 m/min | |

| Cutter | Hardness | 50-65 HRC |

| Cutting tolerance | ± 1 mm | |

| Material | Cr 12 | |

| Operate | Hydraulic cutting | |

| Power | Driving way | Chain 1 inch |

| Main power | 4 kw | |

| Pump power | 3 kw | |

| Voltage | 380v/50HZ,3P or customize as customer' request | |

| Control system | PLC brand | Delta made in Twaiwan |

| Screen | Touchable screen | |

| Language | Chinese and English or add language as customer need | |

| Decoiler | Operation | Manual |

| Weight capicatity | 5 ton | |

| Price | Free as gift | |

| Receiving table | Operation | Manual |

| Length | 3 m | |

| Price | Free as gift |

Roof panel produce on 1000 trapezoidal roofing sheet panel roll forming machine for Palestine

Contact Nona to get more videos or details of this 1000 trapezoidal roofing sheet panel roll forming machine for Palestine and other roof panel roll forming machine.

Trapezoidal roofing sheet roll forming machine

Corrugated roofing sheet roll forming machine

Glazed tile roofing sheet roll forming machine

Tianjin Ironstar Industry Co., ltd is one professional roll forming machine manufacturer with 26 years working experience and 400 workers provide service for you. Products mainly include: 1000 trapezoidal roofing sheet panel roll forming machine for Palestine Trapezoidal steel roof/wall panel roll forming machine, Glazed metal tile roofing roll forming machine, C U channel roll forming machine, Angle bead light keel roll forming machine, Omega truss roll forming machine and T bar roll forming machine, roll up Shutter slat door roll forming machine, door frame roll forming machine, C&Z shape interchangeable roll forming machine, Cap ridge roll forming machine, water gutter roll forming machine, metal sheet cutting machine, metal sheet bending machine for door frame or gutter, metal sheet slitting machine, metal roof or wall board curving machine, metal floor deck roll forming machine, and etc. Roll forming machines above can be customized according to your demands.

1. Q: How to visit our company to see our 1000 trapezoidal roofing sheet panel roll forming machine for Palestine and other roof panel roll forming machines:

A: Fly to Beijing Airport: By fast train From Beijing South station to Cangzhou west station(1hour), then we can pick up you to factory(40min).

A:Fly to Shanghai Airport: By fast train From Shanghai Hongqiao station to Cangzhou west station(4.5 hours), then we can pick up you to factory(40min).

2. Q: What should I provide if I want to customized machine?

A: U need provide profile drawing, material, thickness, voltage and your special requirements.

3. Q: What is the Warranty?

A: Within 24 months, all technical staff are ready to serve you at any time.

4. Q: What can you do if the machine broken?

A: Our machine's warranty period is 24 months, if the broken parts can't repair, we will send new parts replace the broken parts free, but you need pay the express cost if after warranty period. we can negotiate to solve the problem, and we supply the technical support for whole life of equipment.

5. Q: If need technician to workshop to debug and teach, how to do?

A: We sent technician to your country to fix the machine. Buyer should bear cost including: visa, round trip ticket and suitable accommodation, also buyer should pay the salary 100 USD/day.

Похожие товары

Заводская распродажа, трапециевидная R-панель Ibr, машина для прокатки кровельных листов, полностью автоматическая машина для производства плитки

Роликовая формовочная машина для труб водосточных желобов

Стальная кровельная алюминиевая Металлическая Кровельная Панель

Машина для профилирования листового листа

Трехслойная машина для формовки рулонов строительных материалов простая в эксплуатации с системой управления ПЛК завода по производству PPGI

Непрерывная Eps/pu полиуретановая фенольная пенопластовая настенная доска сэндвич изоляционная потолочная панель производственная линия

Устойчивая к атмосферным воздействиям влагостойкая композитная напольная плитка для террасы/производство твердых деревянных плит

Новые поступления

Новинки товаров от производителей по оптовым ценам