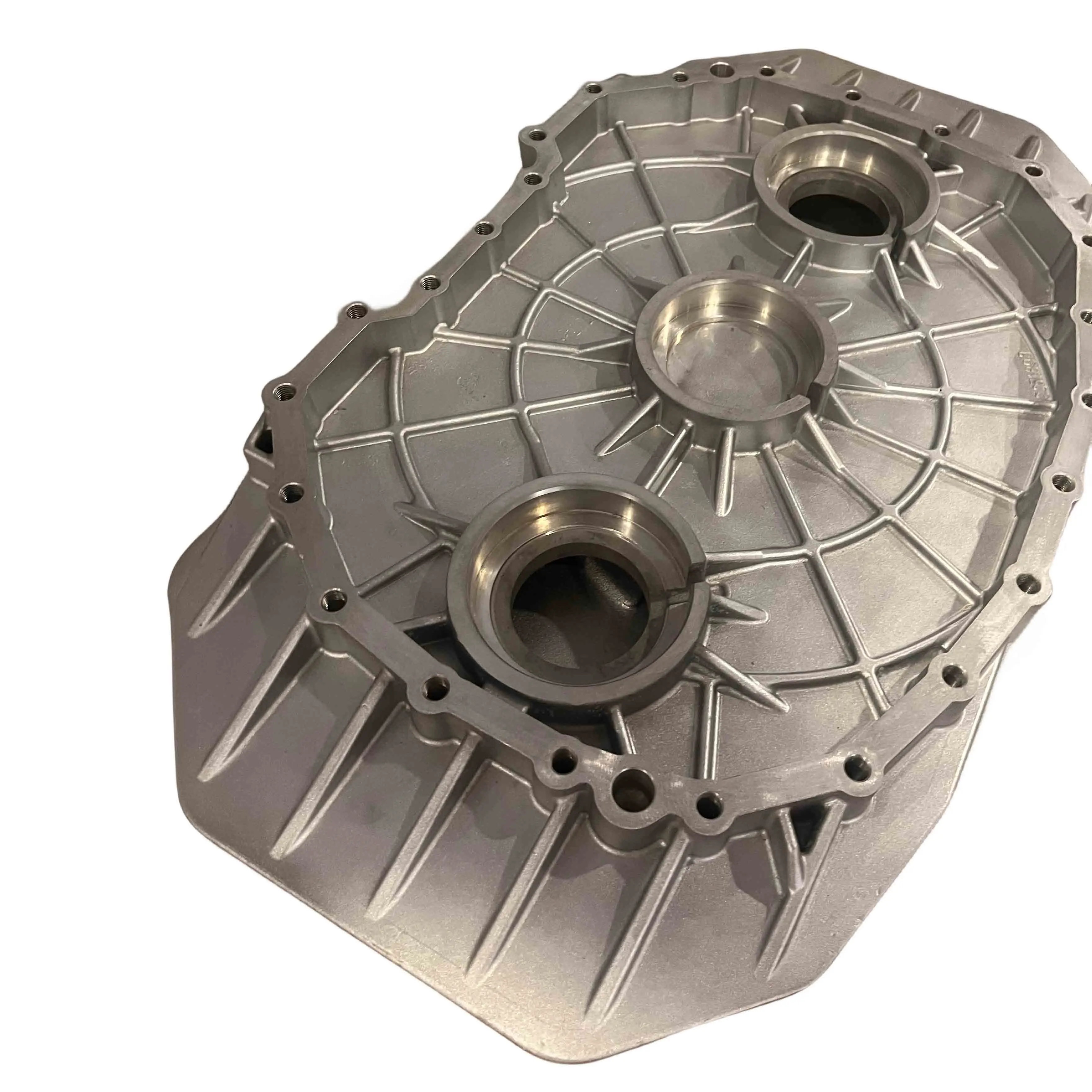

Изготовитель на заказ металлические латунные цинковые литейные формы детали анодированные алюминиевые литые

- Категория: >>>

- Поставщик: Dongguan Winner Manufacture LimitedDongguan Limited

Сохранить в закладки 1600933335215:

Описание и отзывы

Характеристики

Our Service

OEM Factory Precision Custom Stainless Steel Aluminum Titanium Cnc Parts Milling And Turning Machining Service

Custom Service--Contact us for samples.

Custom Service--Contact us for samples.

1.Welcome to request samples.

2.Free drawing design.

3.OEM/ODM one-stop service.

4.+/-0.01MM tighter tolerances.

5.Fast lead times,3-5days for samples.

Special Note:

If you buy for personal use,please click the [Buy Samples] button.

If you need custom you design,please click to [Send Inquiry] to get good price.

2.Free drawing design.

3.OEM/ODM one-stop service.

4.+/-0.01MM tighter tolerances.

5.Fast lead times,3-5days for samples.

Special Note:

If you buy for personal use,please click the [Buy Samples] button.

If you need custom you design,please click to [Send Inquiry] to get good price.

What can we do for you ?

Specification of Products

Product Name | OEM Factory Precision Custom Stainless Steel Aluminum Titanium Cnc Parts Milling And Turning Machining Service |

Service | CNC Machining |

Turning and Milling | |

CNC Turning | |

OEM Parts | |

Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc |

2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | |

5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | |

Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, |

Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, | |

electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |

Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. | |

Drawing format | STEP,STP,IGS,CAD,PDF,DWG,DXF etc or samples. |

Tolerance | +/-0.01mm ~ +/-0.05mm |

Surface roughness | Ra 0.1~3.2 |

Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM |

Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

CNC milling work range: 510mm*1020mm*500mm |

CNC ALUMINUM PARTS

Sand blasting

Multicolor Anodizing Aluminum

Hard Anodizing

Chroming

Polishing

Powder Costing

Brushing etc

conventional material

AL5052 AL 6061

AL 6063 AL 7075

AL 2024 etc

Hard Anodizing

Chroming

Polishing

Powder Costing

Brushing etc

conventional material

AL5052 AL 6061

AL 6063 AL 7075

AL 2024 etc

CNC COPPER PARTS

Conventional Material

Brass

Bronze

Red copper etc

Surface Treatment

Brushing

polishing

Lacquer etc

STAINLESS STEEL PARTS

Conventional Material

45# Q235 Q345B4140 / 4130 Carbon Steel

SS303 SS304 SS316

Spring Steel etc

Surface Treatment

Brushing

polishing

Powder Costing

Chroming

Electropolishing

Blackening

Galvanized

SS303 SS304 SS316

Spring Steel etc

Surface Treatment

Brushing

polishing

Powder Costing

Chroming

Electropolishing

Blackening

Galvanized

Our Factory

Dongguan Winner Manufacture Ltd

1, 12+ years experience in structural parts customization service

2, 5000+m² of factory,100+ employees,20+ professional engineers for designing and quality controling.

3, 1200+ Product Series with standard parts and ODM/OEM SERVICES TO MEET ANY REQUIREMENTS

4, All products WITH FULLY INSPECTION : material inspection/ sample checks/Third party or customer checks.providing considerate before-sale and after-sale service.

2, 5000+m² of factory,100+ employees,20+ professional engineers for designing and quality controling.

3, 1200+ Product Series with standard parts and ODM/OEM SERVICES TO MEET ANY REQUIREMENTS

4, All products WITH FULLY INSPECTION : material inspection/ sample checks/Third party or customer checks.providing considerate before-sale and after-sale service.

Why choose us?(Our differences)

1) Purchase raw materials;

1) Purchase raw materials;

2) Custom Fixture and Machine Adjustment;

3) Communicate with our engineers about the cost composition of production parts.this allow you to better understand the cost components of this quotation.

4) According to your products. while ensuring the product quality,we will choose the most suitable lathe for you to process.help you save cost and time.

5) Surface treatment.if you have requirements for surface treatment of products.we can do also process them.

3) Communicate with our engineers about the cost composition of production parts.this allow you to better understand the cost components of this quotation.

4) According to your products. while ensuring the product quality,we will choose the most suitable lathe for you to process.help you save cost and time.

5) Surface treatment.if you have requirements for surface treatment of products.we can do also process them.

Quality Control

A full inspection of product appearance

A comprehensive examination of the external features and properties of a product to check that the size, shape, color, surface finish, overall cosmetic appearance conform to the design specifications and meet the expected visual aesthetics for the intended customers.

A full inspection of product threads

A thorough inspection of all threaded surfaces on a product to ensure conformity to the thread type, diameter, pitch, depth, fit, This includes checking that the threads are cut or formed to the proper shape, are cleanly machined, deburred with no cracks or tears, so will meet the desired installation and performance criteria.

Installing protective covers over all threaded fasteners

Installing protective covers over all threaded fasteners on a product to prevent damage to the threads during shipping and handling. These covers, typically made of plastic or vinyl, cap each threaded hole and debris that could prevent proper engagement of the fasteners during final assembly. They are removed once the product reaches its final destination

Certifications

Customer Review

FAQ

1. Can we get a sample to test ?

Of course , Most of produts we provide for free to help you test .

2. What is your common MOQ ?

OUR common MOQ is 1 pc, bulks order based on your requirements.

3. How can we pay the order ?

2. What is your common MOQ ?

OUR common MOQ is 1 pc, bulks order based on your requirements.

3. How can we pay the order ?

Usually you can pay by TT on alibaba bank acount or our HK bank account.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-5 weeks.

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-5 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment..

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment..

Похожие товары

Литье под давлением алюминия и магния

Китай литейное литье из серебра услуги по литью алюминия под давлением

Литье из Китая литье серебра обслуживание алюминия под давлением

Изготовленные на заказ алюминиевые детали для литья под давлением услуги гравитационного грубого

2 262,52-2 601,89 ₽

Фабрика продает алюминиевые отливки для деталей машин

Индивидуальное литье под давлением из алюминия Высокоточное Литье песка цинкового инвестиционное

452,51-678,76 ₽

Алюминиевое литье под давлением

905,01-1 131,26 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $