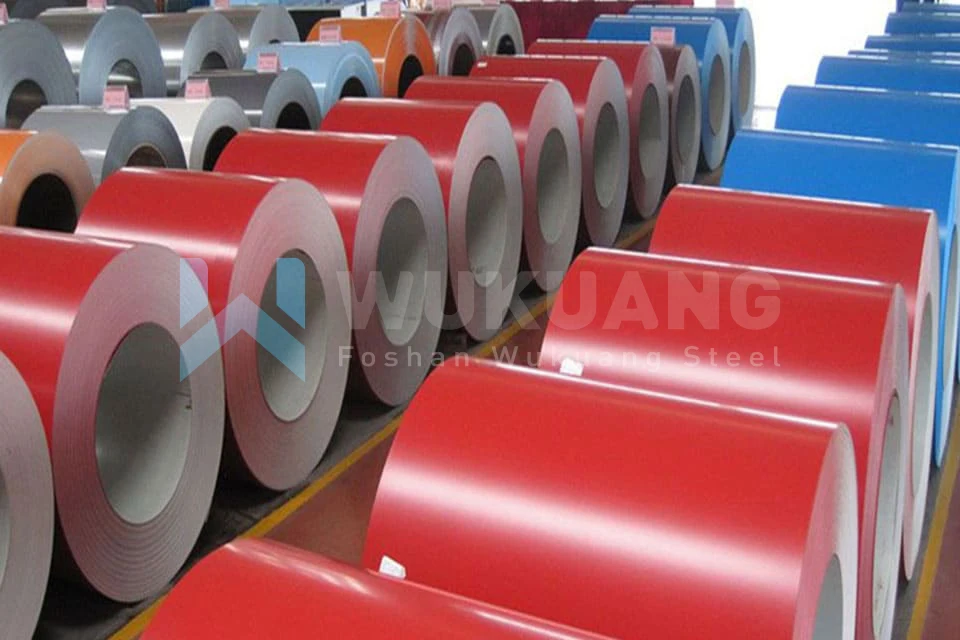

Оцинкованная катушка с цветным покрытием

- Категория: >>>

- Поставщик: Foshan Wukuang Steel Co. Ltd.

Сохранить в закладки 1600937691346:

Описание и отзывы

Характеристики

Products Description

Spangle usually refers to the flash effect or silver light on the surface of galvanized steel plate in the metal material industry. It refers to the shiny pattern or texture formed on the surface of galvanized steel plate due to a specific galvanizing process. Spangle mainly appears on hot-dip galvanized steel plates.

The formation of Spangle is due to the cooling and solidification of molten zinc during galvanizing. Specifically, when the steel plate is immersed in molten zinc for hot dip galvanizing, zinc reacts with the surface of the steel plate to form an alloy layer of steel and zinc. During the solidification of the alloy layer, zinc crystals will form crystals with different sizes and shapes on the surface of the steel plate. These crystals are Spangle, and they reflect light, resulting in a shiny silvery white or gold effect on the surface of the steel plate.

The size and shape of Spangle will be influenced by many factors, including zinc plating process, composition of zinc liquid and surface state of steel plate. Common Spangle shapes include Regular Spangle, Irregular Spangle, Minimized Spangle and Normal Spangle. The existence of Spangle makes galvanized steel sheet have unique appearance characteristics, and also adds certain decorative effect to the product.

It should be noted that the formation of Spangle will not affect the corrosion resistance of galvanized steel sheet. However, in some applications, such as automobile outer panels or some precision equipment, it may be required that the surface of steel plate has a non-Spangle appearance, so we can choose products without Spangle or remove Spangle in subsequent processing.

The formation of Spangle is due to the cooling and solidification of molten zinc during galvanizing. Specifically, when the steel plate is immersed in molten zinc for hot dip galvanizing, zinc reacts with the surface of the steel plate to form an alloy layer of steel and zinc. During the solidification of the alloy layer, zinc crystals will form crystals with different sizes and shapes on the surface of the steel plate. These crystals are Spangle, and they reflect light, resulting in a shiny silvery white or gold effect on the surface of the steel plate.

The size and shape of Spangle will be influenced by many factors, including zinc plating process, composition of zinc liquid and surface state of steel plate. Common Spangle shapes include Regular Spangle, Irregular Spangle, Minimized Spangle and Normal Spangle. The existence of Spangle makes galvanized steel sheet have unique appearance characteristics, and also adds certain decorative effect to the product.

It should be noted that the formation of Spangle will not affect the corrosion resistance of galvanized steel sheet. However, in some applications, such as automobile outer panels or some precision equipment, it may be required that the surface of steel plate has a non-Spangle appearance, so we can choose products without Spangle or remove Spangle in subsequent processing.

Product Details

Coating Surface Treatment | ||||||

Electro-galvanized | Hot-dip galvanized | AI-Zn alloy coated | Hot-dip AI-Zn coated | |||

Chrome-free passivation | Chrome acid passivation | Chrome acid passivation | Chromate Passivated | |||

Chrome-free passivation+oiling | Chrome acid passivation+oiling | Chrome acid passivation+oiling | Non-chromate passivated | |||

Phosphatization | Chrome-free passivation | Chrome-free passivation | Chromate Passivated+oiling | |||

Phosphatization+oiling | Chrome-free passivation+oiling | Chrome-free passivation+oiling | Non-chromate passivated+oiling | |||

Chrome-free fingerprint resistant | Chrome-free fingerprint resistant | Common fingerprint resistant | Anti-fingerprint | |||

Self-lubricating | Self-lubricating | Chrome-free fingerprint resistant | Non-Chromate anti-fingerprint | |||

Oiling | Oiling | Oiling | Oiling | |||

Without treatment | Without treatment | Without treatment | Without treatment | |||

Type | Grade | Standard |

Conventional galvanized steel sheet | Type A, Type B, Type C | ASTM |

DX51D,DX52D,DX53D,DX54D,DX56D,DX57D,DX58D | EN | |

Structural galvanized steel sheet | SS Grade 33/37/40/50/80 | ASTM |

S220GD, S250GD, S280GD, S320GD, S350GD, S550GD | EN | |

General galvanized steel sheet | SGCC, SGCD1, SGCD2, SGCD3, SGCD4 | JIS |

DX51D, DX52D, DX53D | GB | |

Material use galvanized steel Sheet | SGHC, SGH340, SGH400, SGH440 | JIS |

Deep drawing galvanized steel sheet | DDS, EDDS | ASTM |

Common carbon structural steel | Q195, Q215, Q235 | GB |

Main Products

Applications

Substrate | Brand | C (Wt%) | Si (Wt%) | Mn (Wt%) | P (Wt%) | S (Wt%) | Alt (Wt%) | Ti (Wt%) | Nb (Wt%) |

Cold rolled sheet | DC51D+Z, DC51D+ZF | ≤0.10 | / | ≤0.50 | ≤0.035 | ≤0.035 | / | / | / |

DC52D+Z, DC52D+ZF | ≤0.08 | / | ≤0.45 | ≤0.030 | ≤0.030 | / | / | / | |

DC53D+Z, DC53D+ZF | ≤0.08 | / | ≤0.40 | ≤0.030 | ≤0.030 | / | / | / | |

DC54D+Z, DC54D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | ≤0.020 | ≤0.015 | ≤0.10 | / | |

DC56D+Z, DC56D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | ≤0.020 | ≤0.015 | ≤0.10 | ≤0.10 | |

Hot rolled sheet | DD51D+Z | ≤0.10 | / | ≤0.50 | ≤0.035 | ≤0.025 | / | / | / |

DD54D+Z | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | ≤0.020 | ≤0.015 | ≤0.10 | / |

Grade | Yield Strength ,Mpa | Tensile Strength,Mpa | Elongation, % A80mm | ||||||||||

<0.3mm | 0.3-0.5mm | 0.5-0.7mm | 0.7-1.0mm | 1.0-1.6mm | ≥1.6mm | ||||||||

DC01 | 140-280 | ≥270 | ≥24 | ≥26 | ≥28 | ≥30 | ≥32 | ≥34 | |||||

DC03 | 140-240 | ≥270 | / | ≥30 | ≥32 | ≥34 | ≥35 | ≥36 | |||||

DC04 | 130-210 | ≥270 | / | ≥34 | ≥36 | ≥38 | ≥39 | ≥40 | |||||

DC05 | 120-180 | ≥270 | / | ≥35 | ≥38 | ≥40 | ≥40 | ≥41 | |||||

DC06 | 110-170 | ≥260 | / | ≥37 | ≥39 | ≥41 | ≥42 | ≥43 | |||||

DC07 | 100-150 | ≥250 | / | ≥40 | ≥42 | ≥44 | ≥44 | ≥44 | |||||

Grade | Yield Strength, Mpa | Tensile Strength, Mpa | Elongation, % L0=50mm, b=25mm | ||||||||||||

<0.25 mm | 0.25-0.3 mm | 0.3-0.4 mm | 0.4-0.6 mm | 0.6-1 mm | 1.0-1.6 mm | ≥1.6 mm | |||||||||

SPCC | / | ≥270 | ≥25 | ≥28 | ≥31 | ≥34 | ≥36 | ≥37 | ≥38 | ||||||

SPCD | 240 | ≥270 | ≥27 | ≥30 | ≥33 | ≥36 | ≥38 | ≥39 | ≥40 | ||||||

SPCE | 220 | ≥270 | ≥29 | ≥32 | ≥35 | ≥38 | ≥40 | ≥41 | ≥42 | ||||||

SPCF | 210 | ≥270 | / | / | ≥37 | ≥40 | ≥42 | ≥43 | ≥44 | ||||||

SPCG | 190 | ≥270 | / | / | / | ≥42 | ≥44 | ≥45 | ≥46 | ||||||

Company Profile

FAQ

FAQ

Q1: Can you offer free samples?

A: We will return the sample fee once getting the mass production order.

Q2: What is the delivery time?

A: Fast delivery in 5 days, up to order quantity.

Q3: What is your terms of payment ?

A: 30% T/T in advance ,balance before loading or LC at sight.

Q4: Do you provide custom made Products service?

A: Yes,custom made is acceptable.

Q5: Can I go to your factory to visit?

A: Of course, welcome to visit our factory anytime.

Q6: What product information do I need to provide?

A: Please kindly tell us what’s the steel grade, specification (thickness, length, width), surface treatment requirement do you have and quantities you need to purchase.

Q7: It's my first time to import steel products, can you help me with it?

A: We will do our best to give the solution and help you on the business.

Q8: If products not comply with the contract demands, what will you do?

A: We will compensate the customer for all the loss without any hesitation.

Похожие товары

Горячеоцинкованная решетка, сверхпрочная решетка, композитная решетка.

2 160,13 ₽ - 3 780,22 ₽

Горячеоцинкованная сварная стальная решетка

Aluminum Flat flooring expansion joint covering for basement in shopping centre

3 024,18 ₽ - 3 240,19 ₽

Хит продаж, нержавеющая сталь, материал для кухни, для ванной, дома, нескользящая канализационная решетка, крышки траншей для дренажа

540,04 ₽ - 2 700,16 ₽

Покрытие из стального волокна 13-25 мм с крючком, медные металлические волокна, конструкция, прочность на растяжение, 2850 Мп-пластины

144,73 ₽ - 230,06 ₽

Высококачественная труба с цинковым покрытием, труба для жидкости SGCC/SGCD/SECC/DX51D/DX52D, круглая квадратная прямоугольная оцинкованная труба для котельной трубы

49 682,86 ₽ - 60 483,48 ₽

Цветные алюминиевые Конвейерные Ленточные ролики из алюминиевого сплава для печатного оборудования

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $