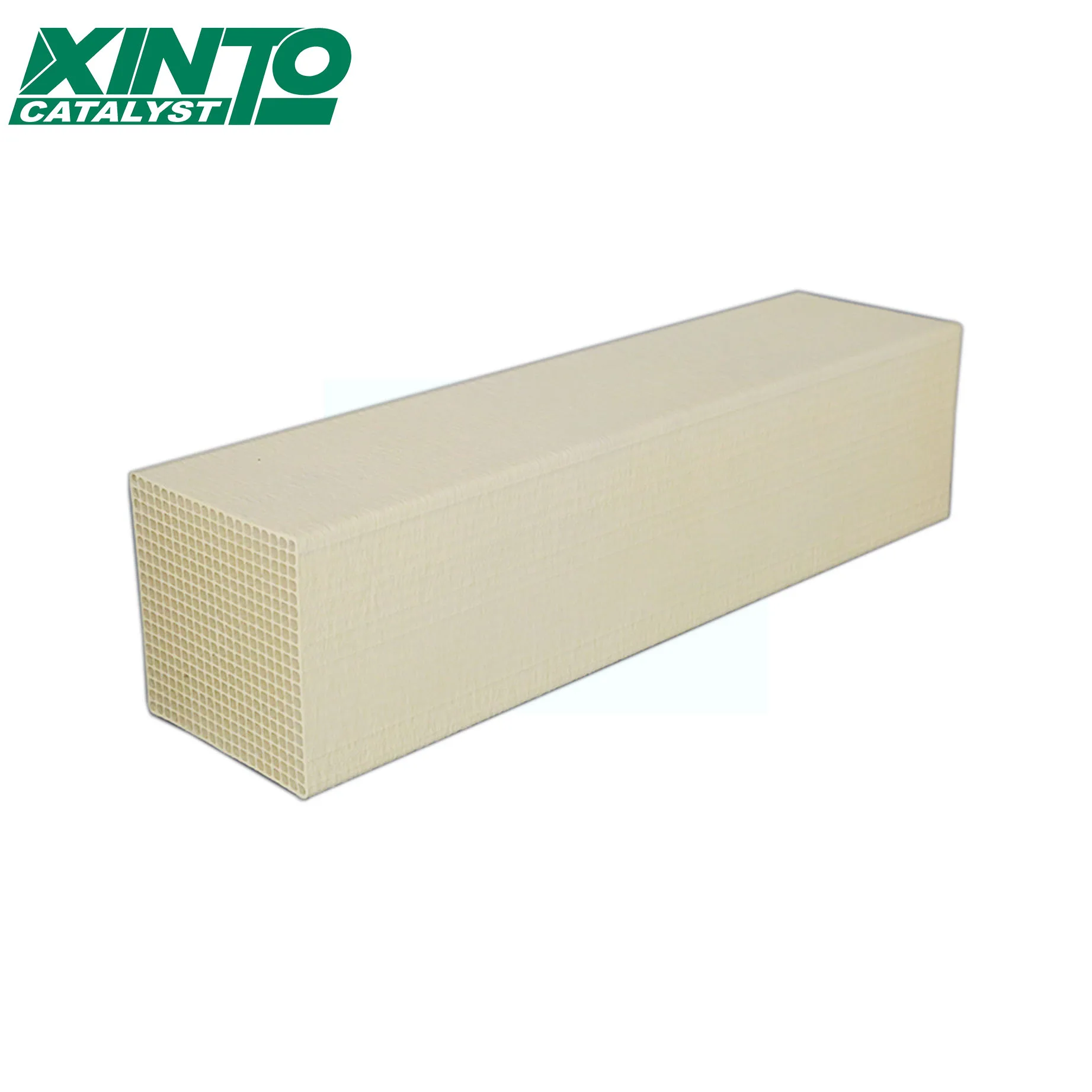

Промышленный сотовый Scr катализатор XINTO для удаления большой удельной поверхности

- Категория: >>>

- Поставщик: Qingdao Zhongyan Supply Chain Management Co. Ltd.

Сохранить в закладки 1600938331325:

Описание и отзывы

Характеристики

Company Information

Shandong Xintuo New Material Technology Co., Ltd. was reborn in Xinyi Group. Xinyi brake has become the No. 1 brake brand in China since 1992. Since 2006, the group has started to research exhaust systems, three-way catalysis of automobile internal combustion engine and diesel engine; Later, because China positioned the development direction of automobiles in the direction of new energy electric vehicles, we carried the technology accumulation in automobiles and transferred them to industrial applications in 2012, which received great support from Xinyi Group; And we officially started commercial production and operation in 2014;

The group was restructured this year, and our company officially began to operate independently, in order to adapt to market changes and development faster; The success of the past few years is also because we have a research and development team led by a doctor. The transformation from internal combustion engine to industrial application is not a great challenge for us; It is this unique core advantage that makes us stand out in the fierce domestic market competition, gradually expanding from SCR denitration to CO, CH4, VOCS, NH3, and dioxin removal. .

Company Structure:

QINGDAO ZHONGYAN SUPPLY CHAIN MANAGEMENT CO., LTD

As the export service window of XINTO Catalyst, Zhongyan branch company maximizes the advantages of Qingdao in talent, logistics and port location to better serve customers all over the world.

SHANDONG XINTUO NEW MATERIAL TECHNOLOGY CO., LTD

Head Company and Production base of XINTO Catalyst, on the basis of domestic production equipment, the company independently designs automated production lines and reduce employees in the production line, thereby minimizing the impact of human factors on product quality and make it stable. Meanwhile, the company has increased the improvement research on equipment, optimized producing process in many aspects, and ensured that the product performance and quality are always in a leading position in the industry.

Patents and Certs

Product Description

We Make Efforts to be the best supplier of SCR Denitration Catalyst:

ULTRA-LOW TEMPERATURE SCR DENITRATION CATALYST

The ultra-low temperature denitrification catalyst developed by the company has good denitrification performance under low sulfur and dust conditions at 150-180°C in the ultra-low temperature section. The denitrification efficiency can reach more than 90%. It is widely used in Vaiours industries such as natural gas boilers and kilns.

LOW TEMPERATURE SCR DENITRATION CATALYST

The company's self-developed low-temperature denitration catalyst adopts advanced production technology. The catalyst has very good denitration performance in the low temperature section (180-280 °C), it can process high concentration of nitrogen oxides, and the denitration efficiency is over 95%. Low-temperature denitration catalysts are widely used in coking plants, sintering machines, small industrial boilers, industrial furnaces, glass and other industries.

MEDIUM TEMPERATURE SCR DENITRATION CATALYST

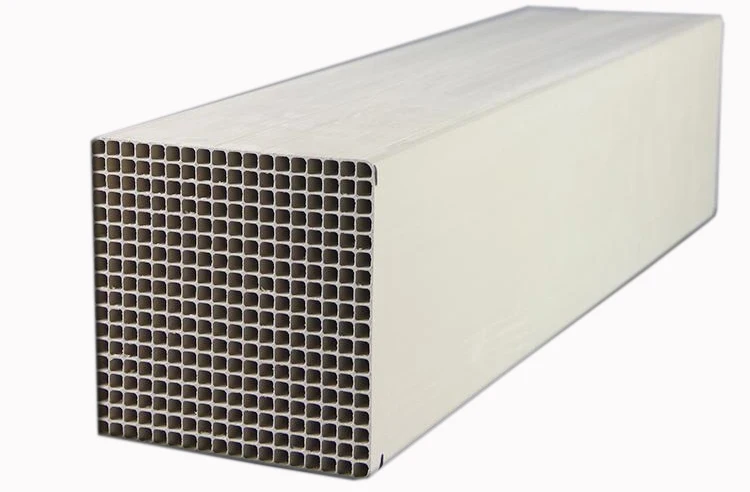

This type adopts a front-end hardening process, increase the wear-resistant coating and maintain a long mechanical life. The raw material is made of high quality anatase titanium dioxide with large specific surface area. It is optimized for the flue gas environment of various industries and has strong anti-poisoning ability. The product design can be carried out for different flue gas conditions, with strong pertinence and excellent product performance. Widely used in power plant boilers, industrial boilers and other industries, to adapt to temperature range of 280-420°C.

HIGH TEMPERATURE SCR DENITRATION CATALYST

This type adopts international advanced technology and high-quality cordierite catalyst carrier. Coating composite molecular sieve catalyst, to improve the activity and stability of the catalyst at high temperature. It can be widely used in 300-550°C working conditions, and can be customized according to different industry conditions. It is commonly used in various high-temperature flue gas fields such as gas kiln and diesel engine.

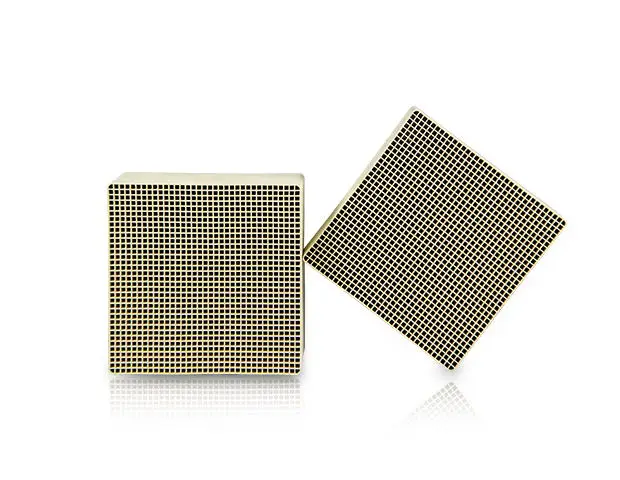

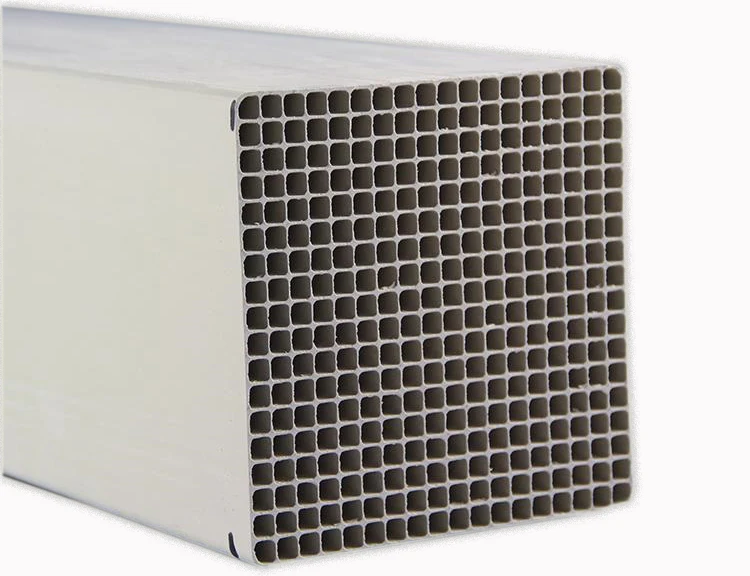

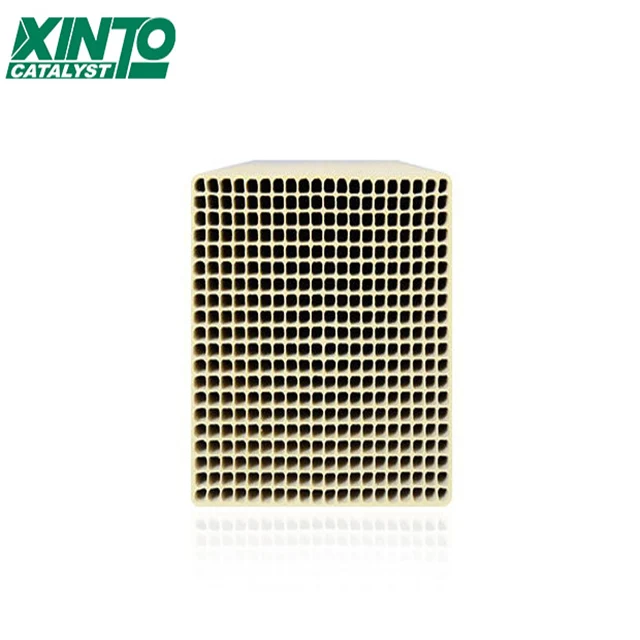

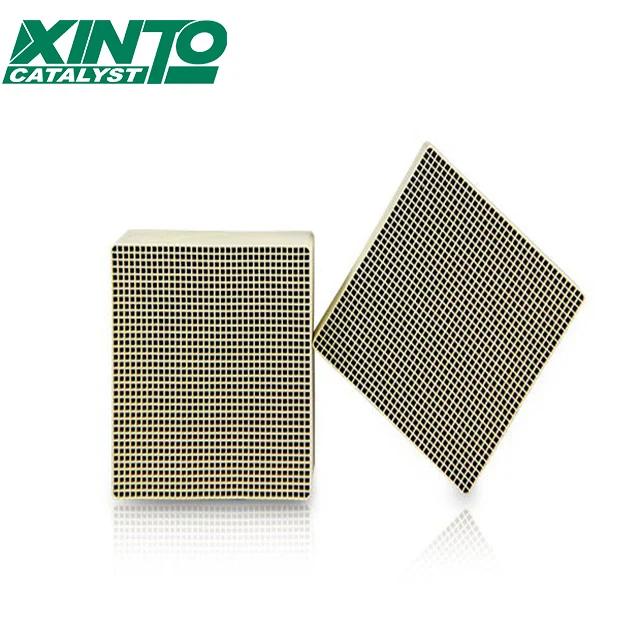

Product name | SCR Denitration Catalyst |

MOQ | 2 Cubic Meter/Cubic Meters (Min. Order) |

Place of Origin | Shandong, China(Mainland) |

Brand Name | XINTO |

Cross Sectional Dimensions | 150×150mm |

Length | 500-1300mm |

Chemical Composition Content | 1%~5% V205, 5%~10% W03, and Ti02 mostly |

Application | DeNOx |

Denitration Efficiency | >90% |

Classification | Catalyst |

Other Names | Chemical Reduction Via a Reducting Agent |

Lead time | 30 days |

Life time | 24000 hours |

Factory Equipment

DeNOx Applications

Based on the introduction of SCR honeycomb catalyst production technology and technology, we digest and absorb and innovates, independently develops and produces honeycomb catalysts that can adapt to the harsh domestic flue gas conditions. The comprehensive product index meets or exceeds the foreign products in the same category, breaking the foreign monopoly and becoming the only company in China that has mastered all the core technologies of the catalyst.

The “XINTO” brand medium and low temperature denitration catalyst developed by the company has broadened the conventional treatment temperature zone of SCR denitration catalyst, and widened the treatment area to 180-420 °C. On the basis of extensive service to the power industry, the company adheres to science and technology. Innovation, leading the future development strategy, has successively developed professional catalysts in the fields of cement, steel, chemicals, ceramics, glass, etc., as well as denitrification synergistic removal of dioxin multi-effect catalysts. The company's products cover medium and high temperature V-Ti-R based (300-420 ° C), medium and low temperature Mo-Ti-R based (180-300 ° C) and other low temperature range catalyst products.

The products have been widely used in thermal power, steel, coking, sintering, ceramics, glass, cement, chemical and other fields. After long-term successful proved operation, it has high efficiency of denitration and long service life.

At present, "XINTO" brand medium and low temperature SCR denitration catalyst has been subdivided into individual formulas adapted to different industries and fields, and special catalyst products can be customized according to customer requirements, and efforts are made to solve the worldwide problem of NOx treatment under low temperature conditions.

Finished Products

Performance Cases

Environmental Fairs

Factory Advantages

The company owns a stable technical team and builds close cooperation with Tsinghua University, Nanjing University of Technology, Zhejiang University and other foreign technology companies. We are currently building a new state-level laboratory to continuously enhance the company's technical strength. The catalyst regeneration and recycling project is also being prepared, and we will have the ability to recycle and recycle waste catalyst (hw50) within 1-2 years.

On the basis of domestic production equipment, we independently design automated production lines to reduce employees, thereby reducing the impact of human factors on product quality, making product quality stable and controlling production costs. Meanwhile, we are enhancing the research and improvement of production equipment and processes, and optimized in various aspects’ details of equipment and processes, in order to ensure that product performance and quality always in a leading position in the industry.

FAQ

1. Are you manufacture or trading company?

We are manufacture, this company on the Alibaba is our Specialized subsidiary for exporting.

As the export service window of XINTO Catalyst, Zhongyan maximizes the advantages of Qingdao in talent, logistics and port location to better serve customers all over the world.

We warmly welcome you to visit our head company.

2. How do you provide right product for our project?

We have a professional technical team, specific software and test equipment, we will provide you a form to fill,

it will help us to know about the flue gas condition; then we can design the catalyst solution for you.

3. Can you provide on-site guidance for installation or other things?

Yes, if it is necessary, we can send technical engineer to you for the on-site guidance.

4. What's the advantage of your company?

Producing Advantage

We have advanced automated production lines and equipment, reduce the impact of human factors on the product quality, Use the experience of ISO/TS16949 auto parts production quality management mode for reference, and make sure delivery the goods in time.

1> 10% Larger Specific Surface Area

2> Activity Start Sensitive

Supply Scope Advantage

1> Homogeneous Extrusion, main elements V2O5, W03, TiO2

2> Coating on Carrier, Cordierite, Fe/Cu-based Molecular Sieve, Pt, Rh, Pa

Technical Advantage:

We know engineering as well as our catalyst, we can provide design consultation and optimization, to help evaluate the original project scheme.

We can provide technical consulting services, including SCR design, operational guidance, and on-site services, including installation technology, start-up operations and equipment inspections.

After-sales Service Advantage

For exporting, we have 30 years experience of international trading service, know rules very well.

Похожие товары

XINTO, ведущий в отрасли, Scr денитрационный сотовый керамический катализатор для цементных заводов Sncr катализатор

Фабрика Catalyst 99% жидкости бензин использования агента для Rocket cas no.102-54-5 ферроцен

Специальный отвердителя для двухкомпонентный домашний текстиль лср жидкая силиконовая резина

Общего Назначения Жидкий Герметик, Анаэробный Герметик

Фабрика 99% бензин и дизель добавки (cas: 102-54-5) оранжевый порошок ферроцен

Октадецилтриметил аммоний Chlo-ride CAS 112-03-8 честное обслуживание качество первая своевременная

Высококачественная хлорауриновая кислота/тетрахлорауриновая кислота HAuCl4 CAS No.:16903-35-8 по лучшей

Новые поступления

Новинки товаров от производителей по оптовым ценам