Машина для приготовления кукурузных хлопьев

- Категория: >>>

- Поставщик: Jinan Dayi Extrusion Machinery Co. Ltd.Jinan Ltd.

Сохранить в закладки 1600939121556:

Описание и отзывы

Характеристики

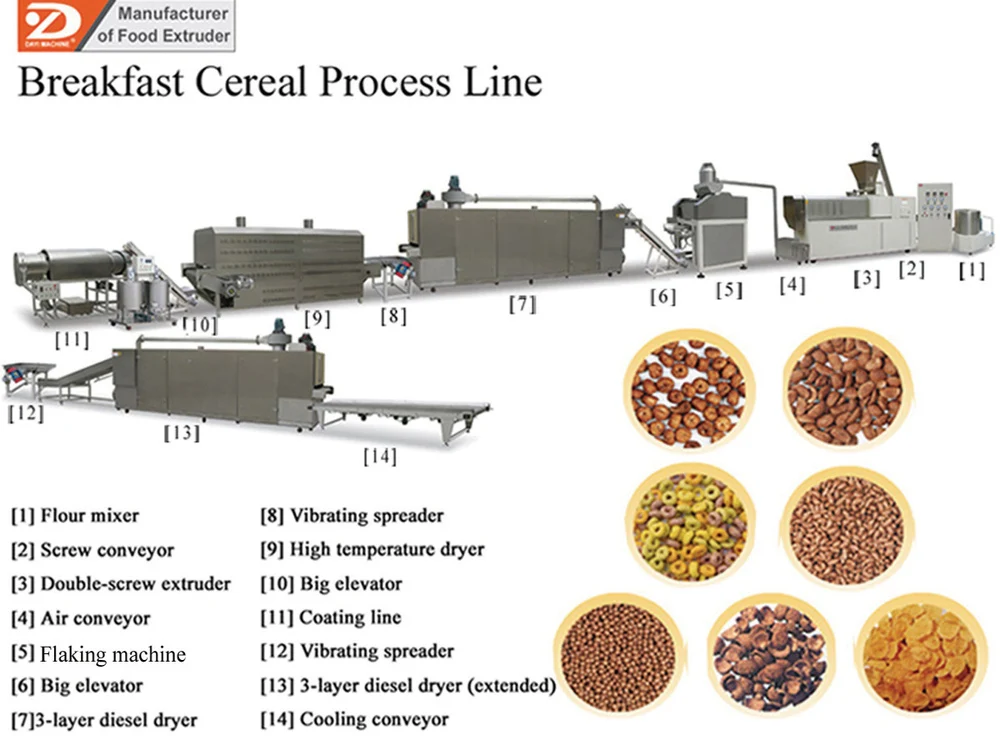

Double Screw Extrusion Machine Corn Flakes Plant

Breakfast cereal food and corn flakes food are crispy food which are produced by breakfast cereal process line using grist as basic material. It is fast and nutritional food with given structure in granule shape, flake shape adn animal shape. Its outstanding characteristic is containing abundant compound carbohydrate and meal fibre. Breakfast cereal can not only strengthen lots of microelement such as vitamin and mineral, but also be added with cocoa powder, sugar powder, honey, and maltose.

You can enjoy it directly by mixing with coffee, milk, yoghourt or functional drink. Children can eat breakfast cereal as sweet crispy snack. There are also natural corn flakes,sweet corn flakes and salty corn flakes according to different flavors.

Model | Installed Power | Power Consumption | Power Consumption | Dimension |

SLG65-CJ | 85.97kw | 56kw | 100~160kg/h | 34500*2000*2600mm |

SLG65-DJ | 88.56kw | 57kw | 100~160kg/h | 35500*2000*2600mm |

SLG70-A | 119.06kw | 82kw | 200~250kg/h | 35600*2000*2800mm |

Main Features

1) Direct transmission betwe en motor and gear box,reducing energy consumption.

2) Feeding,main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption.

3) Screw is made of alloy steel with long life.Segmental assembled screws are applied tomore kinds of materials and products

4) Automatic lubrication system can lower down power consumption and prolong the life.

5) Double screws feed equal materials forcibly.

6) Hanging mould and knives seat and bearing knife adjusting system can adjust the kniver exactly and swiftly.

Transmitting drive power: 0.37kw

Speed of press roller: 0~85rpm

Dimension: 1800×1700×1650mm

Driving power: 5.5KW

Heating power: 54KW

Width of mesh belt: 1200mm

Dimension: 12670 × two thousand × 2890mm

ensure uniform arrangement of materials.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Are you manufacturer or trader? | Certainly we are manufacturer. Welcome to visit us to check it! | ||||||

Do you supply formula to buyers? | Yes, we provide free basic formulas to buyers. | ||||||

What kind of fuels we can choose? | You can choose gas, diesel, electricity, steam as fuels, but please tell us when you ask for quotation. | ||||||

What is the size of your company's machines? How to solve the problem if it's not suitable? | We can customize it for you,the best way is telling us your workshop area, then we will draw a draft for you to ensure the rational use of your space. | ||||||

If the power supply is not 3ph 380V 50HZ, could you offer the suitable machine? | Yes, we can offer the suitable machine according to your power supply, for example 3ph 380V 60HZ, 3ph 415V 60 HZ, 3ph 220V 60HZand so on. | ||||||

Do you supply packing machine? | Yes, we can provide you with a packaging machine. | ||||||

Похожие товары

Машина для производства кукурузных хлопьев чтобы сделать кукурузные хлопья

Завтрак Хлопья Кукурузные производственная линия

Машина для Производства Кукурузных Хлопьев

Небольшая автоматическая машина для производства хлебных крошек Панко экономичный экструдер сушки панировочных сухарей

Автоматическая машина для производства мелких конфет

Цельноценные машины для малого бизнеса китайского производства

Машина для изготовления закусок детей

Новые поступления

Новинки товаров от производителей по оптовым ценам