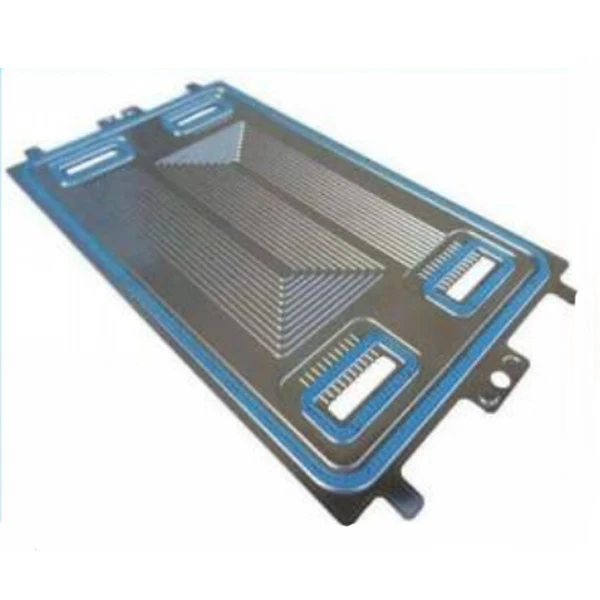

Топливный элемент Графитовая биполярная пластина PEMFC водородная Чистая энергия окислительно восстановительная батарея стационарная электростанция для хранения

- Категория: >>>

- Поставщик: Huizhou Liyuan New Energy Co. Ltd.

Сохранить в закладки 1600943357771:

Описание и отзывы

Характеристики

Workshop

The first company in China to complete the development of carbon paper and composite carbon board chain.We focus on the research, development, production, sales and overall solutions of key carbon-graphite materials in the new energy fields

such as proton exchange membrane fuel cells, lithium ion batteries and

flow batteries, and take it as our responsibility to help the "double carbon" strategy.

The main products include carbon paper based on hydrogen fuel cell,

gas diffusion layer, composite graphite bipolar plate, conductive paste

based on lithium battery, electric heating film and silicon-carbon anode

material, etc., which have been mass-produced, and the product

performance and production capacity have reached the domestic

advanced level, and the market prospect can be expected.

such as proton exchange membrane fuel cells, lithium ion batteries and

flow batteries, and take it as our responsibility to help the "double carbon" strategy.

The main products include carbon paper based on hydrogen fuel cell,

gas diffusion layer, composite graphite bipolar plate, conductive paste

based on lithium battery, electric heating film and silicon-carbon anode

material, etc., which have been mass-produced, and the product

performance and production capacity have reached the domestic

advanced level, and the market prospect can be expected.

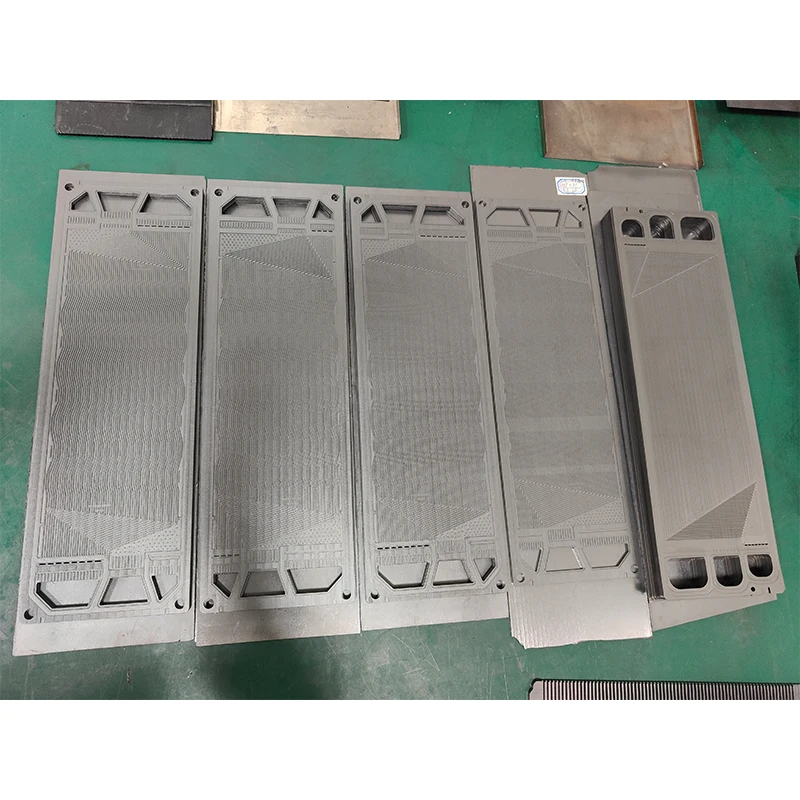

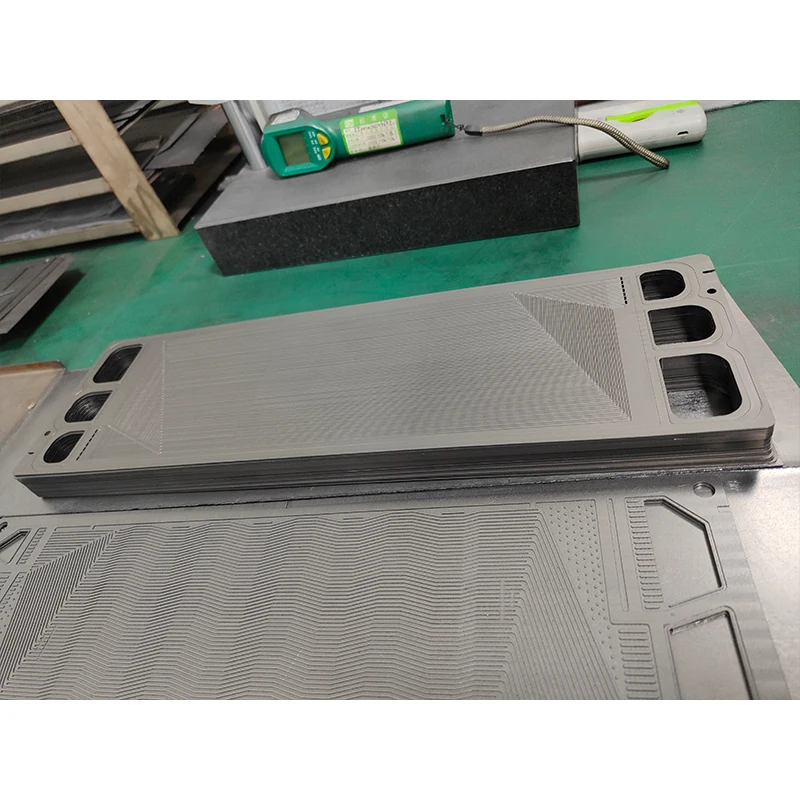

Gas diffusion layer Composite graphite bipolar plate

Heating film Conductive paste

Carbon electrothermal film series products

Clothing heating film PACK heating film for vehicle 5G base station heating film

Motorcycle seat heating film Automobile seat heating film

Carbon paper diffusion layer

Technical Parameter | Our Product | Japan TORAY Sample |

electric resistance (mΩ·cm) | Vertical: ≤ 40; Parallel: ≤3.0 | Vertical: 80; Parallel: 6.0 |

Thermal conductivity W/(m.k) | Vertical: ≤ 2.0; Parallel: ≤25 | Vertical: 1.7; Parallel: 21 |

Air permeability ml.mm/(cm2.hr.mmAq) | >2200 | 2000 |

poriness % | 78 | 78 |

volume density (g/cm3) | 00.2-0.46 | 0.2-0.46 |

Graphite bipolar plate

Our Product | electrical conductivity /S.cm-1 | bending strength MPa | Corrosion potential EcorrV(vs.SCE) | Corrosion current density Icorr(µA/cm2) |

DOE Standard | >100 | >25 | --- | <1 |

1 | 182.1 | 40.12 | --- | 0.83 |

2 | 166.2 | 46.32 | -0.07 | 0.78 |

3 | 132.6 | 55.74 | -0.22 | 0.67 |

4 | 105.7 | 63.58 | -0.11 | 0.92 |

Benchmarking Toray Japan: the cost is reduced by 40%, the air permeability is increased by 10%, and the amount of binder is significantly reduced.

In-situ growth of carbon nanofibers for reinforcement

Benchmarking the US DOE standard: the plate thickness is reduced from 1.0mm to 0.6mm, the strength is more than doubled, the accuracy is 10 microns, and the industrial chain is fully localized.

R&D design | content |

Gradient carbon-paper composite microporous layer technology | Usually, it is to improve the pore structure of the base layer, prevent the electrode catalytic layer from "flooding" and prevent the catalytic layer from leaking to the base layer during the preparation process. |

High uniformity dispersion technology of carbon brazing in papermaking | The fiber is well dispersed in water, which reduces the flocculation of pulp and increases the evenness of papermaking. |

Strengthening technology of carbon brazing dimension CVD | CVD process can minimize the amount of adhesive and greatly improve the flux and mechanical properties of diffusion layer. |

Improvement of micro-cracks in microporous layer | Reduce the diameter of water droplets and reduce the probability of GDL flooding blockage. |

Optimization of resin types | Several resins with excellent comprehensive properties were selected to improve the mechanical properties of bipolar plates. |

Resin modification | The resin was optimized by modification to improve the comprehensive properties of composite bipolar plate. |

Graphite modification technology | By modifying or treating the surface of graphite particles, graphite was modified to improve the performance of bipolar plate. |

Похожие товары

Стандартная распылительная Форсунка Vee Jet с встроенным сетчатым фильтром H-VVL H1/4vl, плоская Форсунка вентилятора

Алмазная втулка молоток диск абразивная роликовая щетка Грубая поверхность личи франкфуртская каменная цилиндрическая

45,00 $ - 50,00 $

Seesa GS сертифицированный Пластиковый садовый ИНСЕКТИЦИДНЫЙ Ulv-распылитель 5 литров 8 литров

Athllete набор из 12-тренировочная жилетка/Лакросса/команда майки

1,02 $ - 1,08 $

250 мл 300 мл 400 мл 500 мл 1000 мл с широким горлышком прозрачные пластиковые банки для конфет и печенья с крышками для упаковки пищевых продуктов

0,12 $ - 0,17 $

Водонепроницаемый велосипедный звонок 120 дБ, самый популярный электрический велосипедный мини-звонок с зарядкой от USB

Мотоцикл для детей мотоциклы 2022 новая модель высокое качество низкая цена белый синий красный детские игрушки продажи

28,00 $ - 31,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $