Высококачественное хрустящее оборудование для закусок без масла машина жарки слоеного кукурузного завода

- Категория: >>>

- Поставщик: Jinan Sunward Machinery Co. Ltd.Jinan Ltd.

Сохранить в закладки 1600945151569:

Описание и отзывы

Характеристики

High Quality Crispy Snack Food Equipment without oil fry snacks machine Puff Corn Plant

Snack food equipment takes corn, rice, wheat, oat, barley, etc as ingredients to make puffed snack/breakfast cereals. Through friction of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

Process

The flow chart of snack food equipment as following: material mixing → extruding →( shaping )→ baking→ flavoring → (cooling)→(packing)

Main Features

1) Simple structure in linear type ,easy in installation and maintaintion.

2) Snack food equipment adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Snack food equipment running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Snack food samples:

Main machine details

Double screw extruder---- the main machine to make snack. It is used to extrude and inflate material and then form it in different shapes. According to different screw design rate to full different technology request.

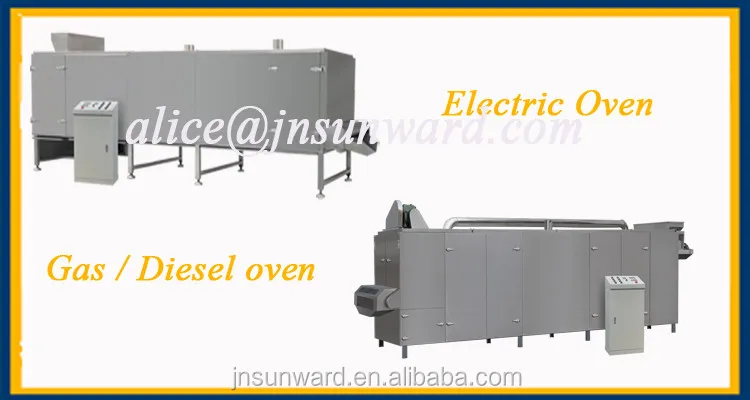

Multilayer oven----it is used to bake the snack food and remove the moisture to make it with crispy teasts. It can take electricity, gas, diesel, steam as main energy. The length and layers can be designed according to the customers' need.

Flavoring system---- it is used to flavor snack with different teasts. It can flavoring snack with different type powder and liquid, for example: sugar, spice, salt, oil, sugar, chocolate, cream and so on. It can be configured flexibly according to different need.

Our Service

Pre service

1. Related machines' technicl parameter wil be supplied.

2.According to custoomer's factory size, factory layout can be provided in advance.

3.According to customer's material cost, general formulation can be supplied well.imen book.

4.Special machine can be designed according to customer's need.

5.Professional advise about market, machines, machine, process, packing can be supplied.

6.Suggesting for shipping agent or helping the book ship as customer required.

After sale service

1. Alocation chart as the buyer's requestswill be supplied.

2. Operation manual will be supplied after shipping.

3. One year warranty, lifet time maintains with cost price.

4. Free easy broken spare parts will be sent with machines.

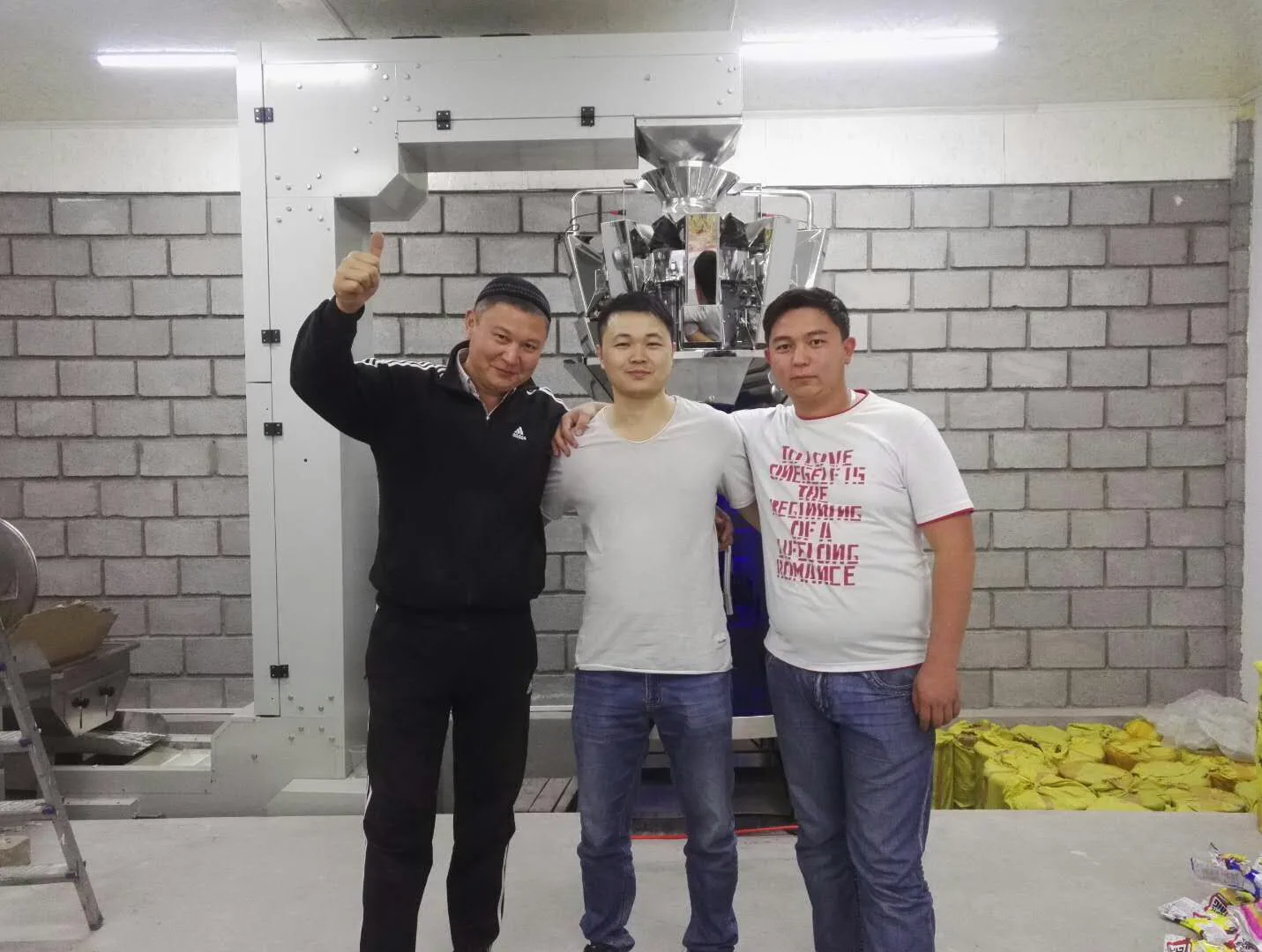

5. Engineer oversea service to install machine and trian workers.

Certifications

Our Company

Jinan Sunward Machinery Co., Ltd is an industry and trade integrated enterprise. The company is committed to R & D extrusion machinery and related ancillary equipments. It is covering mainly machinery and equipment for corn meal milling system, corn flakes/breakfast cereal system, baby food system, corn puff snacks system, pellets system, artificial rice system,soy nuggets system; as well as pet food/fish food system.

Похожие товары

Автоматическая машина для наполнения пасты/машина инъекций и тортов/машина изготовления тортов

Новый продукт идеи 2024 машина для производства фалафеля Аранчини инкрустинга и наполнения крокетов

Автоматический мелкий бизнес воздушный рисовый торт делая машину

Мобильный трейлер для кемпинга грузовик закусок уличный Быстрый Кейтеринг фургон хот-догов с сертификацией Ce

Мобильная уличная тележка для продажи пищи на открытом воздухе

Машина для производства закусок

Полностью Автоматическая машина Вегетарианский мясной соевый протеин Tvp Машина для производства сухого растительного мяса

Новые поступления

Новинки товаров от производителей по оптовым ценам