Горизонтальная декантерная центрифуга SUS304 для обезвоживания крахмала производство Китай заводская цена

- Категория: >>>

- Поставщик: Liaoyang Wintech Industrial Co. Ltd.

Сохранить в закладки 1600945259810:

Описание и отзывы

Характеристики

Product Overview

Customization Separation Equipment Continuous Horizontal Decanter Centrifuge For Sludge With Screw Discharging

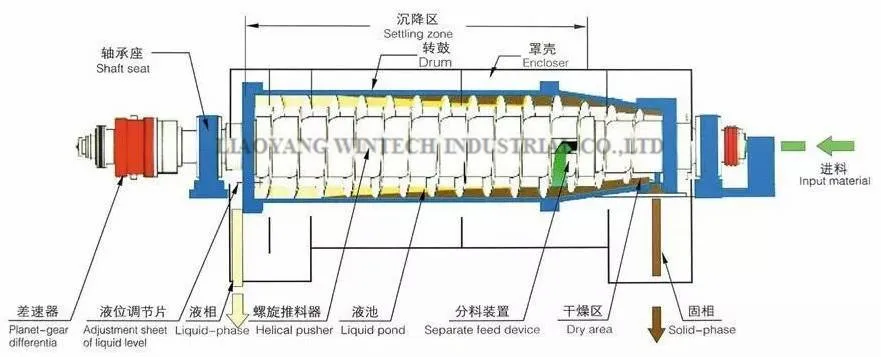

Horizontal screw decanter centrifuge is a kind of spiral discharge settling centrifuge, which is pushes the slag to discharge port at the small end of the drum through the blades on the spiral pusher, and the liquid phase overflows through the overflow hole at the large end of the drum. In order to achieve the purpose of continuous separation.

FEATURES AT A GLANCE

Automatic feeding and discharging

Safety frame

Optional type drum

Easy operation

Wide application

Long lifetime

ADVANTAGES:

1. Two motor, two frequency inverter drive system, realize differential speed stepless regulation and energy return.

2.Spiral stoker blades: Surfacing welding tungsten carbide grinding.

3.Drum cone cylinder material outlet: Replaceable wear resistant, corrosion resistant ceramic alloy bushing.

4.Main bearing: Sweden Janpan

5. Main sealing parts: Taiwan SOG, material is Nitrile butadiene rubber

6. Electrical protection: overload, phase loss, torque protection

7. Main and vice inverter use common DC bus, vice motor’s function is generating electricity ( save electricity)

8. PLC remote control.

Left elevation

Back elevation

Right elevation

Working Principle

This machine is horizontal spiral discharging settling centrifuge, the main machine has a column-cone bowl, spiral stoker,

differential system, bearing seat, base, cover, main motor,vice motor, and electric control chamber. With the high speed rotating of bowl, form strong centrifugal force, making the sludge dehydrate continuously in 24 hours a day.

The main motor through the triangle belt make the bowl rotating, through the planetary gear differential, make the vice motor and spiral differential speed different, realize sludge dewatering and pushing material function, That means differential rotating speed control and torque control. because containing solid rate of sludge may have wave motion, by differential speed control system is the guarantee for speed stability, achieve solid content in sludge is constant, the constant torque control make decanter load in a stable state, the separation effect and flocculation is the best state, so as to ensure the safe operation of the centrifuge.

It has good seal performance (guarantee without material leak in the process of operation), sludge dewatering work in full seal state, makes the environment clean.

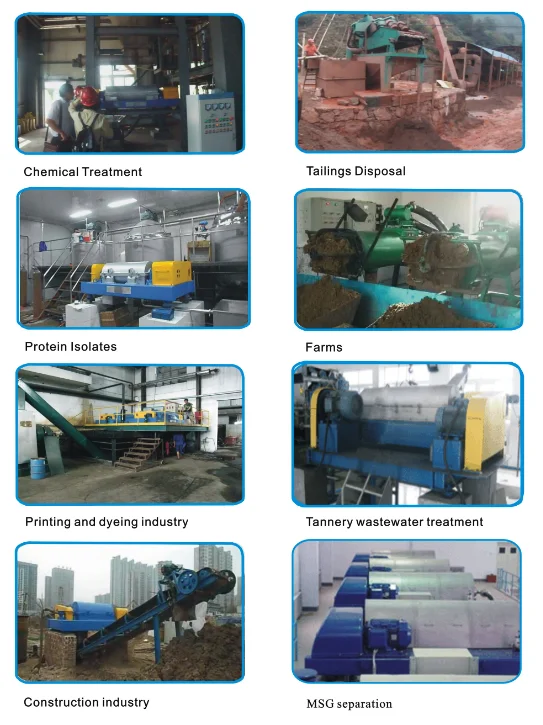

APPLICATION SCOPE:

It is widely used in big capacity solid liquid separation or liquid liquid separation , such as:

1.Foodstuff : various waste oil , coconut oil, fat oil separation, kitchen oil, moto oil, lubricant oil and starch separation etc.

2.Waste water :Textile factory, Dyeing factory , city waste water.

3. Slurry: Mine, city slurry etc.

4. Chemical and pharmaceutical materials separation.

1.Foodstuff : various waste oil , coconut oil, fat oil separation, kitchen oil, moto oil, lubricant oil and starch separation etc.

2.Waste water :Textile factory, Dyeing factory , city waste water.

3. Slurry: Mine, city slurry etc.

4. Chemical and pharmaceutical materials separation.

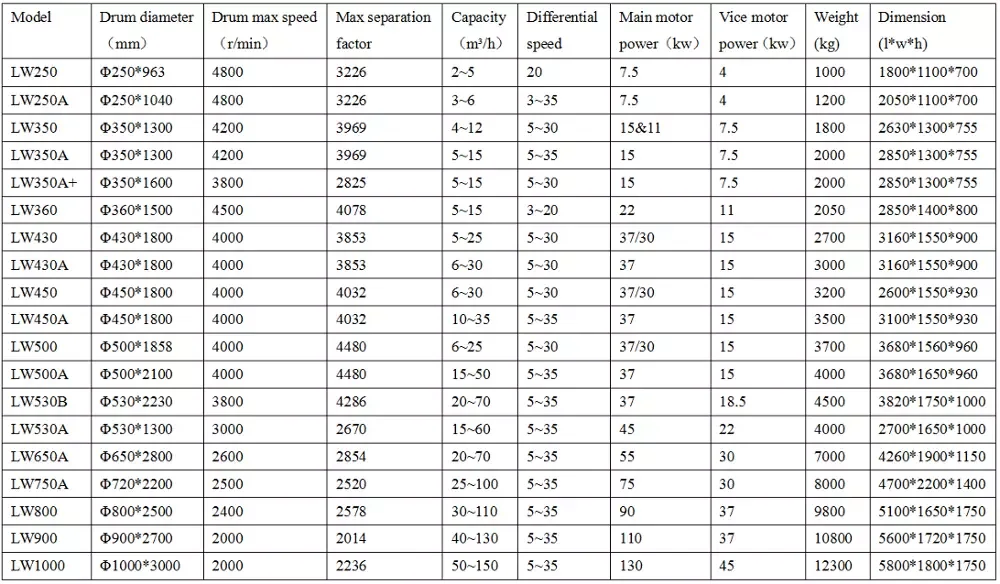

PRODUCT SPECIFICATIONS

Details Images

COMPANY PROFILE

LIAOYANG WINTECH INDUSTRIAL CO.,LTD is specialized in design, development, manufacture and sale of pharmaceutical, food, chemical machinery. Our products include tubular centrifuge, filter centrifuge, decanter centrifuge, disc separator, sedimentation centrifuge etc. As an experienced team, we also help our customer to design and supply the food and drug production line, adopts ISO9001 system management module and manufactures according to GMP and CE standards. Mainly export to Southeast Asia, North America, Africa, Europe etc.

Our company follows strict quality controls and various systematic procedures. We take utmost care of quality at every stage of the manufacturing process.Our research and development wing is our asset that develops and incorporates innovative ideas and products. Our Team is full of experienced and qualified professionals, who have sound knowledge about the quality of our machinery.

Looking to the future with a commitment to design innovation and quality products, supported by an outstanding level of customer service. The unexcelled quality medical machinery can be easily obtained from us because we maintain the quality and standard of our products from incoming raw materials to the finished products.

We sincerely invite you to be our long term relationship friend , and we always prepared to provide our best services for you and would like you to know below we want to present :

1. Each machine is manufactured by professional experienced staff.

2. 12 months warranty + 100% QC inspection Before Shipment.

3. Overseas services provided. Technicians can be sent to spot for guiding the installation and debugging. Training operators and accomplish the commissioning.

4. Consultant services for whole machine life, 24 hours technical support by email and phone.When warranty date expired, lifetime maintenance service is provided and at buyer’s cost.

SIMILAR PRODUCTS

FAQ

1. What data is required to confirm the model?

(1) Materials to be separated (2) Treatment capacity per hour (3) Solid content

2. What certificates do you have?

We can provide CE, ISO 9001, etc

3. What is the warranty period of the equipment?

Normally 1 year warranty

4. Can we visit your factory?

Sure, we sincerely invite you to visit

5. Can we bring our own materials to your factory for experiments?

Sure, you are welcome at any time. We will arrange professional engineers and technicians to do experiments and analyze data for you on site.

6. Can it be customized?

Sure, our equipment can be customized according to the actual requirements of customers.

7. How long is the construction period?

It's about 30 days, but it also needs to be determined according to the specific equipment model, order quantity, etc., But if you need it urgently, please let us know, we can arrange the factory to rush production.

8. Will you provide installation services?

If you need, we can arrange professional technicians and engineers to install and debug on site.

Похожие товары

660nm 850nm ближнего инфракрасного диапазона красный свет терапия устройства данное средство, вылечит вас от облысения кепки красный свет СИД инфракрасный шапочка для волос

85,00 $ - 98,00 $

Непосредственная поставка с завода, Органический Экстракт Какао, 10:1 порошок теобромина 99% какао-порошок

Смартфон портативный для Huawei Nova 7 8i 5t Mate X2 20 30 20 X P20 P30 P40 Lite P50 Pro Plus Honor 20 Gt2 Gt3 Pro Y9a

30,00 $ - 44,00 $

Новый тип, Лидер продаж, длительный срок службы, Хлопушка, колесо, Детская хлопушка

Лидер продаж, сырье lldpe pp ldpe, переработанные пластиковые гранулы hdpe по низкой цене

0,88 $ - 0,95 $

Четырехколесный Электрический скутер для пожилых людей с аккумулятором

665,00 $

Блок управления Fanuc A02B-0210-B501 A02B0210B501

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $