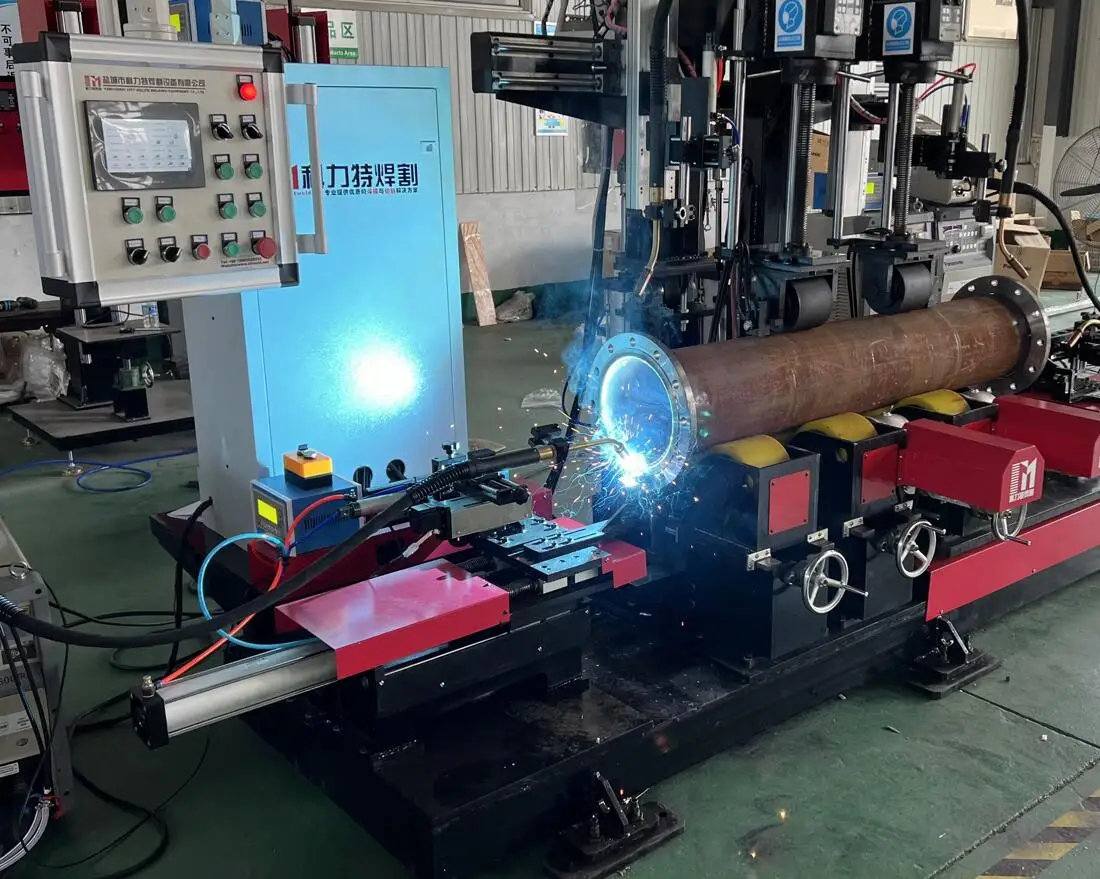

Автоматический сварочный аппарат для труб и фланцев сварочной станции MIG MAG

- Категория: >>>

- Поставщик: Yancheng City Kelite Welding Equipment Co. Ltd.Yancheng Ltd.

Сохранить в закладки 1600947996933:

Описание и отзывы

Характеристики

KLTHFH-4×3000M-YD500FT2 ( List)

| Description | Model | Quantity |

1 | Pipe-flange automatic ring seam welder | 3P*AC380 V ,50/60 HZ 0.75kw AC variable frequency speed control motor, high torque hard helical gearbox Manually rotating the compression assembly Manual 3 Axis torch adjustment device; Welding torch pneumatically lowered Load:3000kg; Maximum clamping diameter: Φ500mm | 1set |

Longest support pipe: 3000mm; Overall length of bed:4640mm ; Track length 3070mm | |||

Pneumatic propulsion, the machine head with flange end mechanical spring tracking device; including manual 3-Axis welding gun adjustment mechanism, the welding torch pneumatic rise and fall. | |||

Rotary console; touch screen + PLC controller, Frequency control, motor is equipped with encoder; Schneider Electric | |||

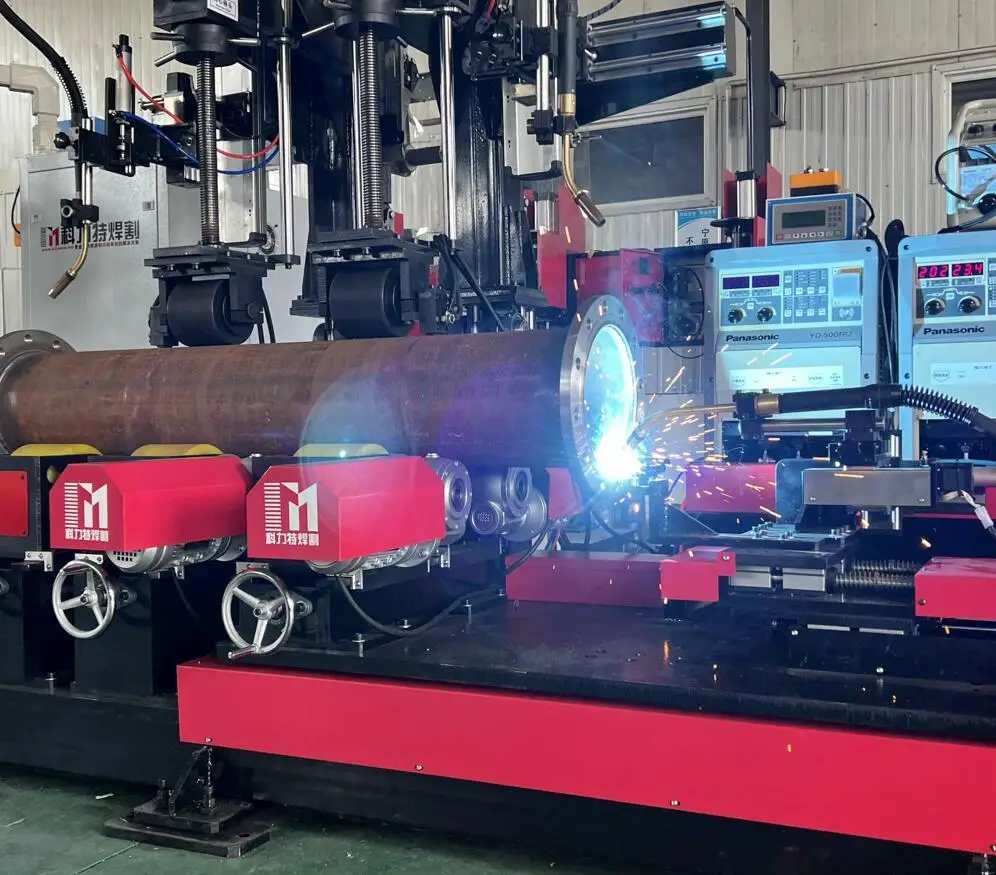

2 | Welding Power Supply | YD500FT2 (CO2/Pulse MAG/ Pulse MIG)(Panasonic) AC 3*380V ,50/60 HZ,Load rate 100% Main welding materials: carbon steel, stainless steel; Cable 5m | 4 set |

3 | Welding torch | 500A, water-cooled welding torch | 4 sets |

4 | Cooling water tank | Model: WL-20L | 4 sets |

5 | Electrical cable | Power cord, welding power ground cord, external conversion box, trachea, etc. | 1 set |

6 | Conductive tip | Φ=1.0mm/Φ=1.2mm, 1 row = 10 pieces | 10 row |

7 | Welding torch cover | 500A welding torch ;1 row = 5 pieces | 10 row |

Main function description of the machine

1.1Workload loading and unloading method: Manually loading and unloading the workpiece, the mechanical tracking device equipped with the left and right cylinders is tightly tightened to the left and right flanges, manually rotating the pressure roller to press the pipe fittings, opening the torch cylinder down switch, adjusting the position of the welding torch, pressing the start button, implementing the pipe method The ring is welded at the same time.

1.2 Welding method: Using the rotating friction force of the Press-fit power roller frame and the pipe fitting, the workpiece is rotated. The machine adopts the gas-shielded welding process, and the load rate of the welding power source is required to be 100%. The 500A water-cooled welding torch and the matched water-cooled water tank can realize long-time welding of the pipe flange. Therefore, we choose the Panasonic -YD500FR2, which has CO2/MAG pulse/MIG pulse function and is applied to carbon steel and stainless steel.

1.3 Workpiece precision requirement:

(1)The surface of the work shall not affect the quality of welding oil, rust, moisture;

(2)Must not affect the positioning of burrs, etc.;

(3)The clearance shall be no more than 1mm;

(4)The consistency error of the same weld group is less than 0.5m.

1. Component:

Pipe flange automatic circumferential welding machine KLTHFH-4 × The 3000M is mainly composed of press mounted power roller frame, non power roller frame, base, left welding joint, right welding joint, control system, Panasonic YD500FT2 (MIG PULSE/MAG PULSE/CO2) welding power supply, welding gun swing device, cooling water tank, carbon dioxide cylinder, etc.

1,Press mounted power roller frame;2,unpowered roller frame;3,base

4,left welding joint;5,right welding joint;6,control system

7,welding power supply;8,welding gun swing device;9,cooling water tank

2. Pipe-flange automatic ring seam MIG welder layout: (picture is for reference only)

The main technical parameters

| Model | KLTHFH-4×3000M |

1 | Track travel | 4000mm |

2 | Effective welding length | ≤3m |

3 | Welding speed | 200~800 mm/min |

4 | Welding power supply | Panasonic -YD500FT2 |

5 | Cooling water tank | WL-20 |

6 | Number of welding guns | 4 sets |

1.Detailed description of the machine:

1.1 Press-fit power roller frame:

It is mainly composed of active roller, manual pressing roller, roller power and bracket welding.

1.2 The manual pressing roller is a driven roller, and the adjusting hand wheel keeps the roller pressed against the workpiece, and the rotating shaft is provided with upper and lower copper conductive rings. The copper conductive ring is a wearing part. The conductive ring should be regularly inspected for serious wear. If the wear is serious, it should be replaced in time. The output negative cable of the welding power supply is connected here.

1.3 The head uses a 3 Axis manual adjustment mechanism for the position adjustment of the torch. In the automatic welding state, the welding gun is pushed up and down by the cylinder.

1.3 Leftwelding head

The left and right welding heads are respectively composed of a mounting base or a movable base, a push-pressing cylinder device, a flange guiding spring mechanical tracking device, and a 3 Axis welding gun adjusting mechanism.

1. mounting base; 2. movable base,; 3. push-pressing cylinder device;

4. flange guiding spring mechanical tracking device;

5. 3 Axis welding gun adjusting mechanism; 6. Welding torch swinging device

* Long-term stock

* Focus on welding and cutting equipment

* View our Factory.

Y.Are you manufacture or trade company ?

M:We are professional manufacturer of many kinds welding and cutting machine.

Y:How to package?

M:Frist layer, covered by plastic film for waterproof,second layer:covered by foam to protect the machine from shaking ,third layer:steel craft case or wooden cases.

Y:Will the package strong enough?

M:Our package is strong enough,nearly all our machine is packed in this way,and the customers receive in good state,So please don't worry,you will receive the welding machine in good condition.,but also can package as your requirement.

Y:How can you guarantee the quality of welding machine?

M: we have passed the ISO test,and if you have time,you can come to our factory to check the machine before order .and we have one year guaranteed,free parts can be send free within one year.

Y:How to install and operate the machine?

M:1.the machine is installed by us before send out,you need to install some parts according to the vedio and manual we send to you.

2.engineer can come to your side to install for you if need

3.install and operate training can be offer in our factory or in your side.

Y:What can I to do if the machine have problem?

M:please contact us at the frist time,and don't repair in your side,we will tell you how to solve it after discuss,we can guaranteed to solve within 24h if not the part break.

Y:how is your after-sale customer service?

M:you can contact our sales manager if have any question,we are online everyday.

Y.How to place an order?

M:1). Tell us the welding material ,welding size ,welding thickness...etc ,the more detailed the better .

2). After view your requirement ,we offer best plan and quotation .

3). Price confirmed ,we can proceed order and arrange shipment to your country.

Похожие товары

Хорошее качество ультразвуковой точечный сварочный аппарат пистолет портативный 800 Вт

Усовершенствованный изоляционный сварочный аппарат для ногтей SB-1250 улучшающий ваши строительные проекты!

Ручной 3 в 1 волоконно-Лазерный Сварочный Станок для очистки резки 2000 Вт 15000 3000 волоконно-металлический сварочный аппарат из нержавеющей стали

Автоматическая машина для сварки и резки медной плетеной проволоки Hwashi оборудование оплетки

Портальная установка для сварки балок коробчатого сечения линии производства

6-осевой сварочный робот AR2010 mig отслеживающий шестиосевой Роботизированный манипулятор волоконно-лазерный аппарат

Yaskawa Motoman робот для дуговой сварки AR2010 TIG/MIG/MAG макс. Рабочий диапазон 2010 мм

Новые поступления

Новинки товаров от производителей по оптовым ценам