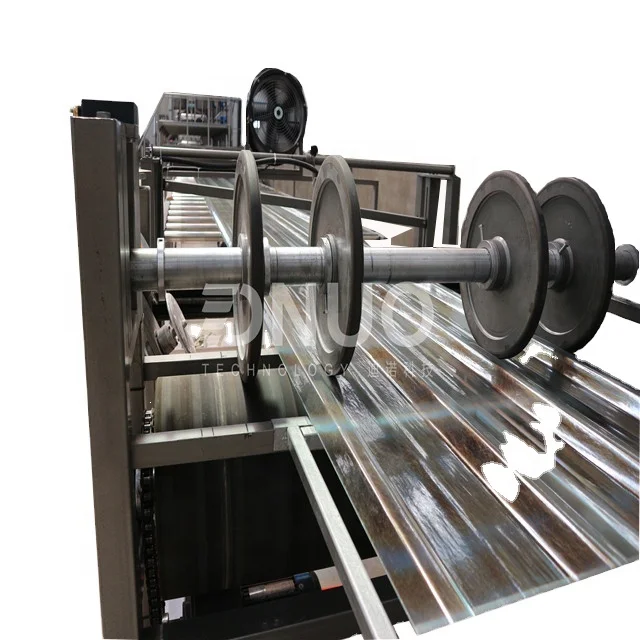

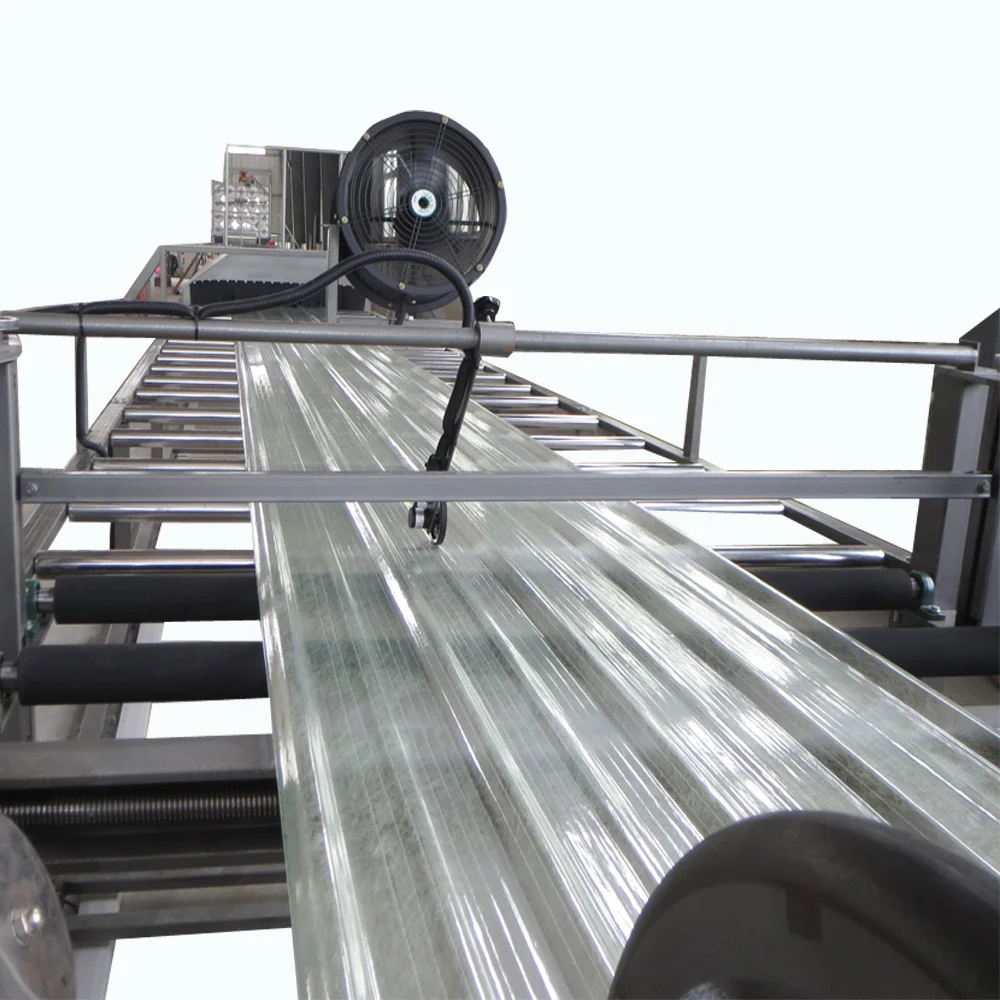

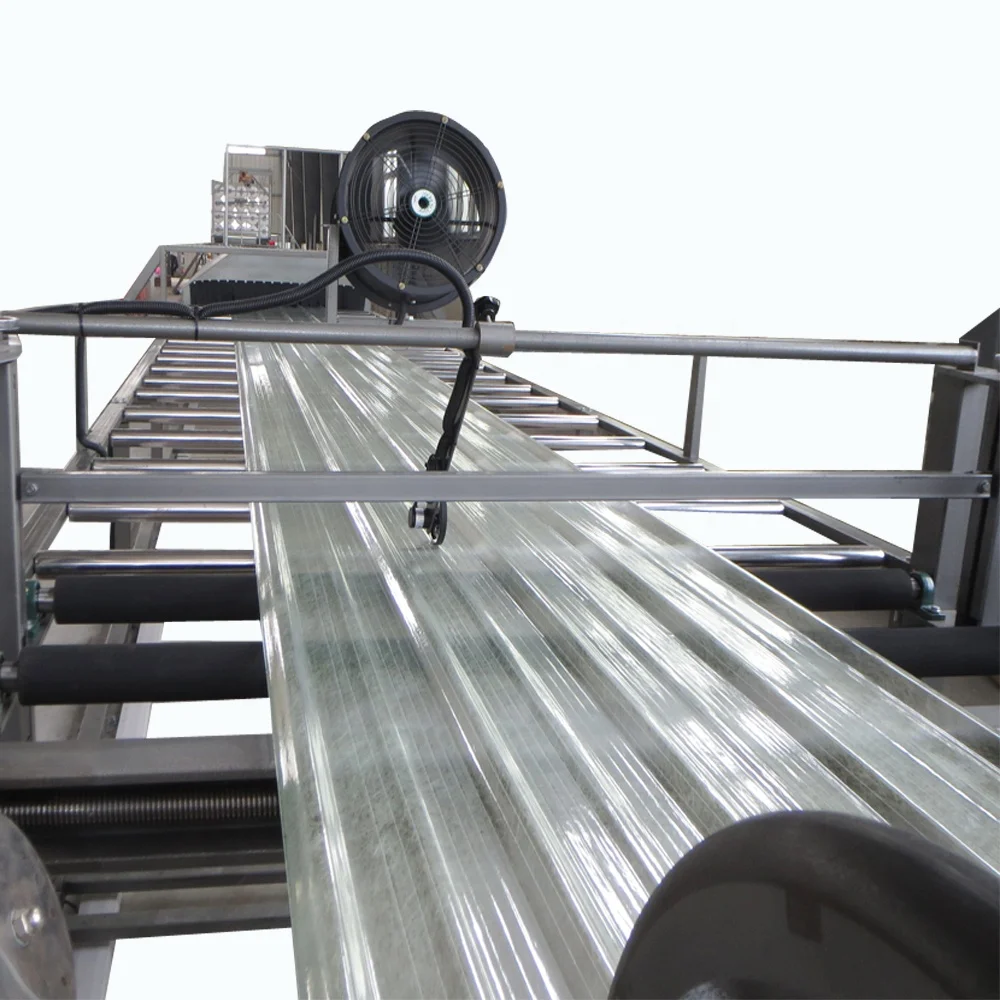

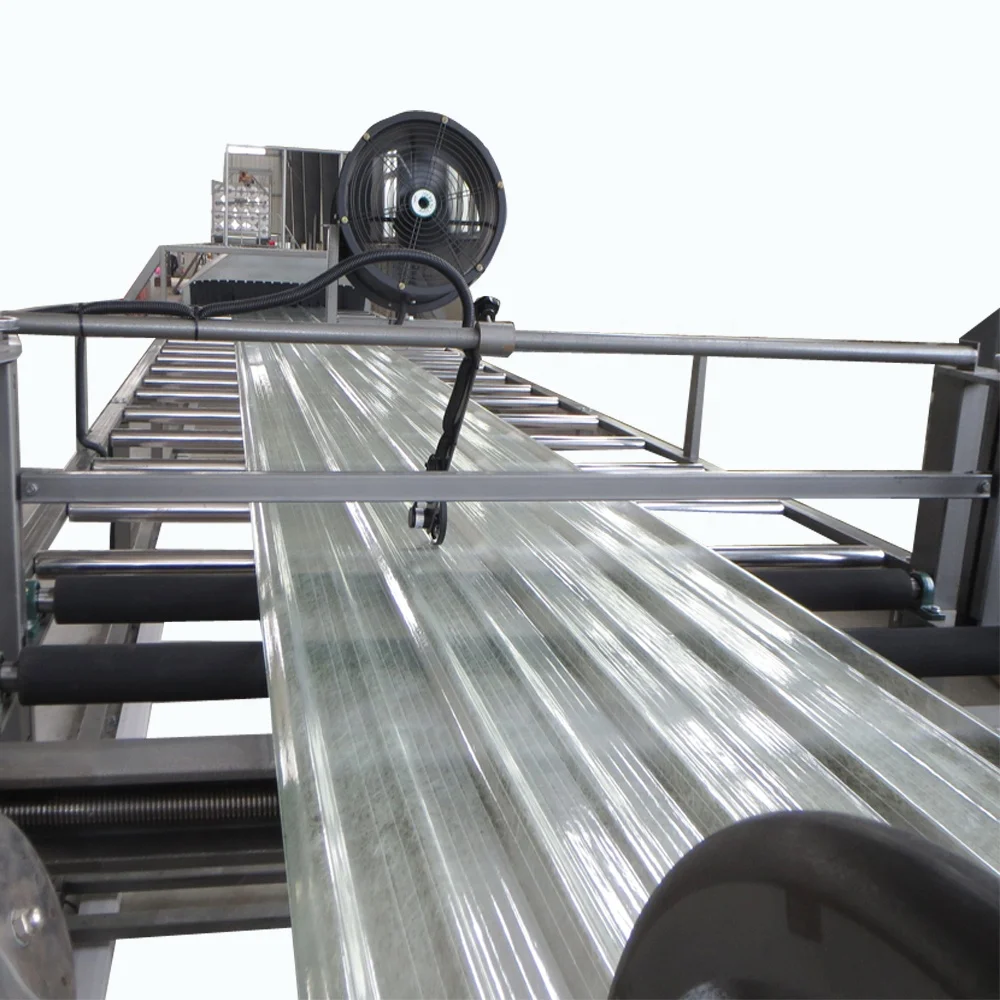

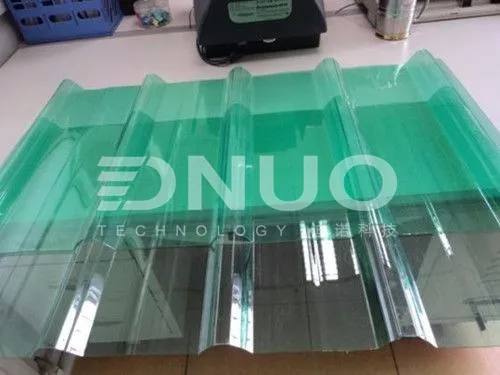

Фабрика Dnuo стеклопластиковый светильник из гофрированного волокна кровельный лист кровельная плитка Кровельная Панель машина для производства листов

- Категория: >>>

- Поставщик: Qinhuangdao Dinuo Technology Development Co. Ltd.

Сохранить в закладки 1600964006435:

Описание и отзывы

Характеристики

Dnuo factoy FRP Corrugated fiber glass skylight roof sheet roving tile roofing panel sheet making machine

Operation staff : | 3-6 people |

production speed : | 2-10m/min |

Sheet width : | maximum effective width of flat sheet is 1500mm |

Wave height : | maximum 130mm |

maximum 130mm : | 0.4mm-4mm |

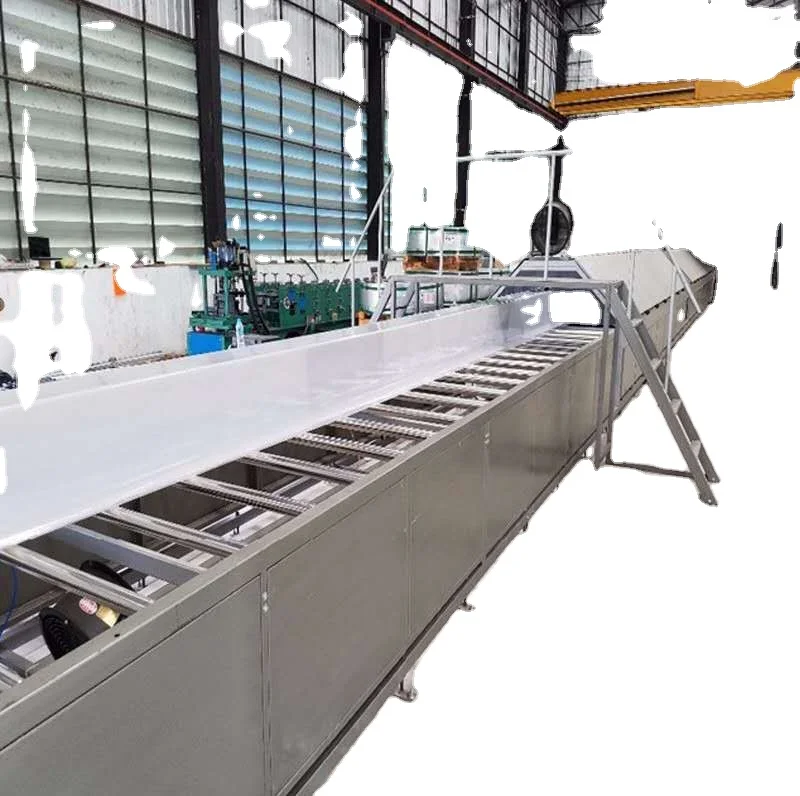

Machine main dimension : | 54m (L) ×1.85m (W) × 3.5m (H) |

Power requirement : | 80kw |

Power consumption : | running power consumption is 25kw/h |

Machine characteristics:

1, Easy operation based on PLC intellectual control system. Only short-term training can make operators complete production independently.

2, Unique arithmetic on temperature control makes oven heating fast, temperature control precise. Which improve quality of products, reduce energy consumption and shorten the preparing time effectively.

3, Roving chopper speed can be synchronous with the production line.

4, Special cross cutting machine and good synchronization performance make cutting accurately.

5, All the machine parts adopt international standard steel make machine with high stability.

6, System failure can be automatically alarmed and show fault point. Make maintenance easily.

7, Particular parts adopt special purpose wire, durable in use.

8, Size and layout of machine can be made according to customer requirements

Resin storage system

the storage tank placed the agitator motor, which can mix the resin with the filler and color paste to reduce the cost of the production.

Metering system

1.Pulse-free metering system achieve the precise metering and permitted add powder fillers, that can reduce the cost of production.

2.The pulse-free metering pumps can real-time control the dosage of raw material, for different raw material we applied different pump. For example, for resin, we adopt the CAM rotor pump; for curing agent and accelerator we applied the plunger pump. The practice proved these types of pump not only assure the quality of products, but also good operation.

3. PLC intelligent control system realized every metering pump automatic match the ratio, no need set the proportion one by one.

Heating oven

PID control temperature accurately, heating sectionalized, reduce power consumption under hot wind control, easily control curing of sheet, attain 90% above, can replace mould needn't shut down machine

Impregnation system

multi-line independent temperature control, able to better adapt change of ambient temperature, quick impregnation, effectively improve the speed of production.

.

Sheet thickness control system

Cabinet heating system.

2.Meanwhile the heating cabinet can open from the side and upper doors. Many factories produce the chamber with upper side open, which will lose a lot of energy and because of big weight of door, it is difficult to open to change the mold or observe the effect of the sheet.

3. In chamber placed the reversible mold frame, that can realize continuous production.

cooling and cutting system

2.\tSpecial cross cutting machine can synchronize with production. Many factories can’t realize the synchronous production, because their cutting machine is static, can’t moving with the sheet. So often met the problem of off tracking

3. in air-cooling zone, our high-power fan can rapidly cooling the sheet. If the aging process is not handled properly, there will be many problems, such as secondary curing, foaming and yellowish.

Industrial plants, warehouses, stadiums, shelters, gardens, agricultural greenhouses, corridors and canopies.Animal and plant greenhouse roofing.Industrial and civil building roofs and walls day lighting, such as factory building day lighting band, the hotel, gymnasium,swimming hall, parking lot.

Qinhuangdao Dinuo Technology Development Co. Ltd.

Packing according to customer requirement, ensure the machine is in a good condition.

Machine parts are packed in containers, classified and fixed to ensure transportation safety. The number of containers required.

varies according to the type of machine. Our nearest port is Tianjin Xingang.

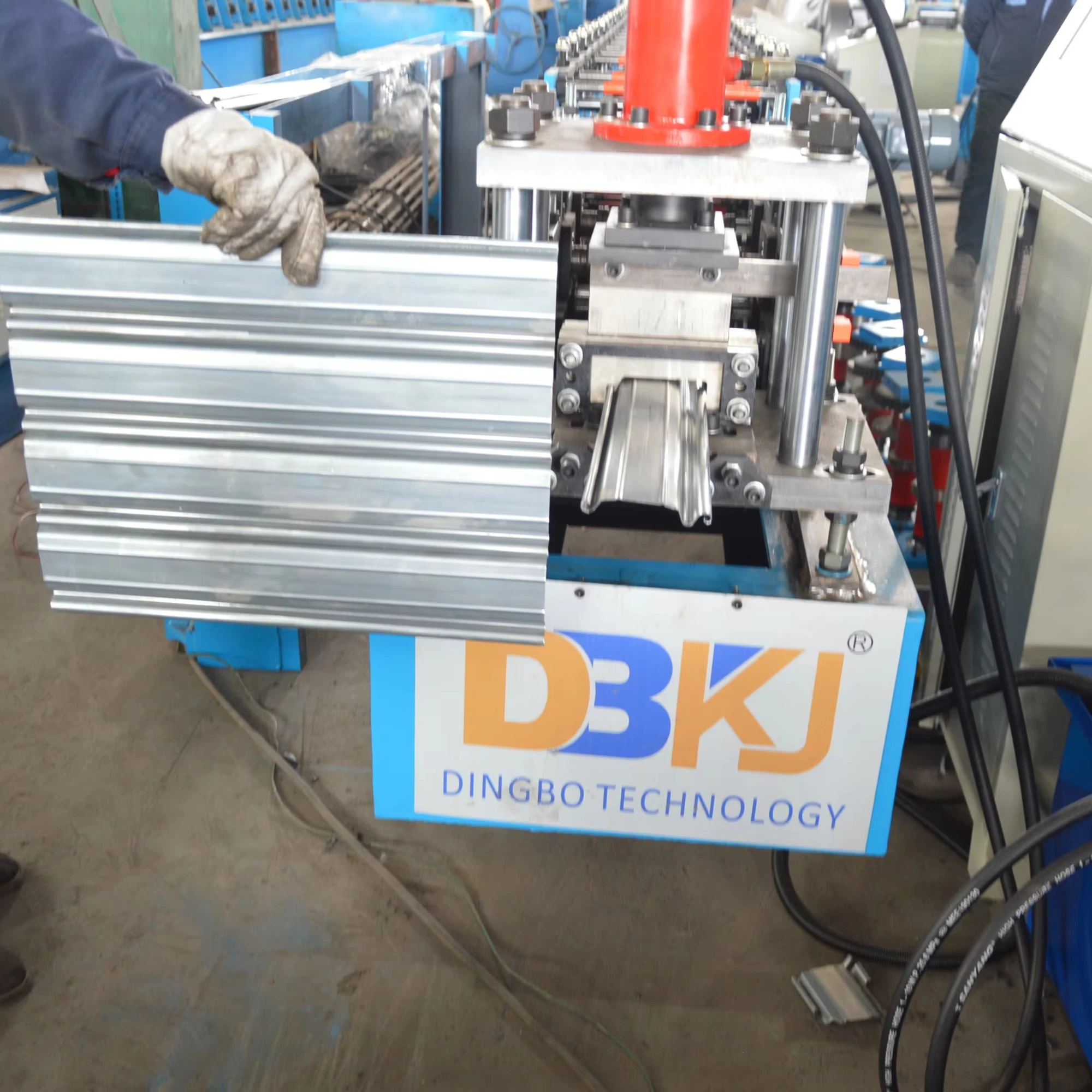

Fiberglass roof sheet machine

Fiber sheet making machine

Fiberglass making machine

Corrugated roof sheet machine

Roof sheets machine

FRP sheet making

single skin skylights making machine

Machine making gutters

Facade panels production machine

Corrugated sheet maker

Machine for making panel for greenhouses

fiber reinforced plastic panel machine

Machine to make corrugated sheet

Похожие товары

Интеллектуальный FRP лист производственной линии

PRFV Стекловолоконный гофрированный прозрачный потолочный светильник кровельная Стекловолоконная плитка листовая машина

DNUO.Интеллектуальный FRP лист производственной линии

Новый продукт FRP гофрированное стекловолокно skylight крыша плитка делая машину

FRP PRFV волоконно-Стекловолоконный гофрированный прозрачный световой люк кровельная листовая плитка Машины

2024 DNUO интеллектуальная машина для производства сточных канавок из стекловолокна теплиц

Высокопроизводительный полностью автоматический роликовый станок

Новые поступления

Новинки товаров от производителей по оптовым ценам