XCJ нестандартная Настройка качества карбидные роторные файлы заусенцы 6 мм Карбид вольфрамовые вращающиеся Заусенцы Набор

- Категория: >>>

- Поставщик: Chengdu Xinchuanjie Cnc Tool Co. Ltd.

Сохранить в закладки 1600978488915:

Описание и отзывы

Характеристики

About this product

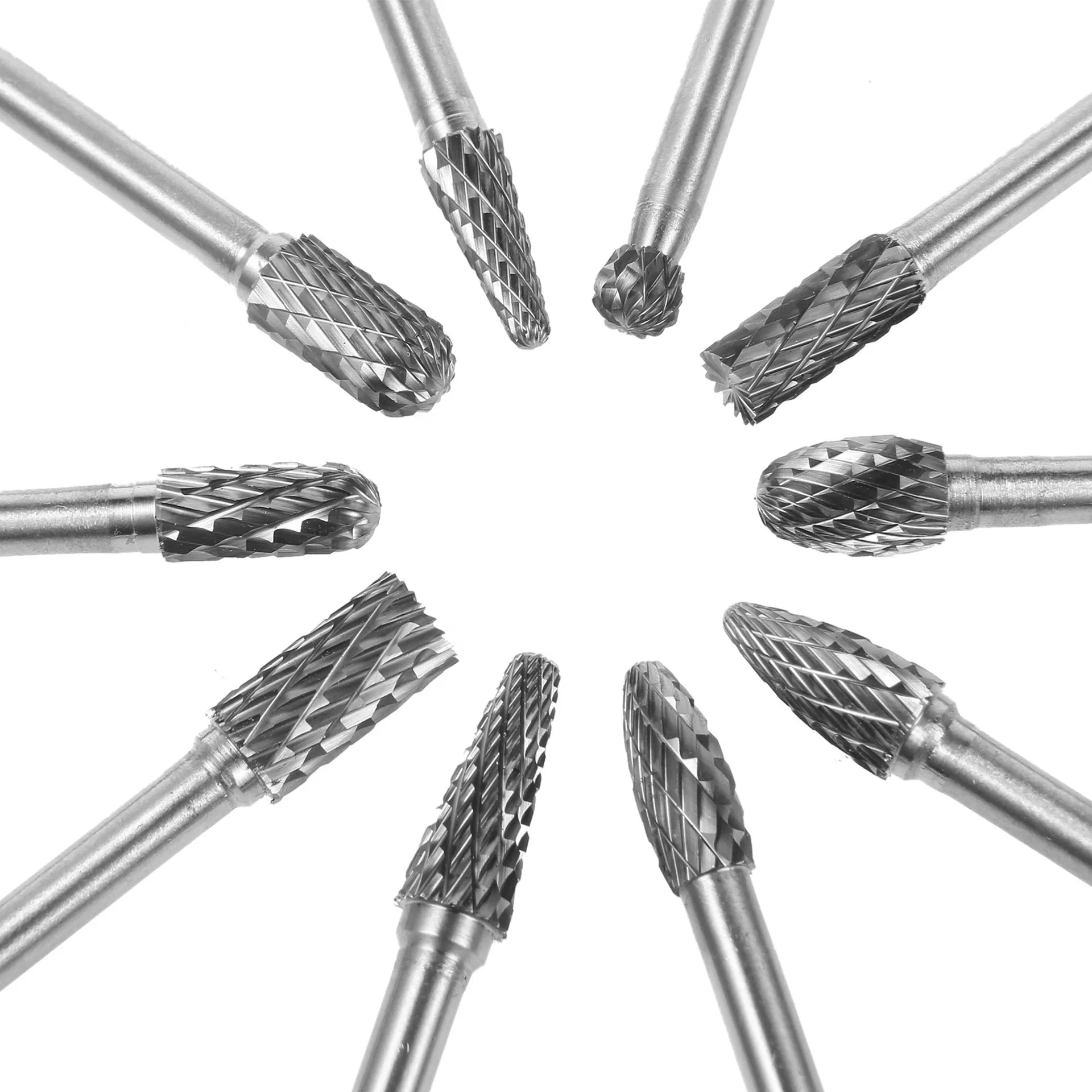

*Product Name: Carbide rotary burr(A12/C10/D10/L06/F12/A06/L12/M12 8PCS) *Material: Tungsten Carbide *Color: silver

*Diameter:A12/C10/D10/L06/F12/A06/L12/M12mm etc.

*Head Hardness: HRA90 Cut Type: Double Cut Coating: Bright (Uncoated)

*They are used in electric, pneumatic, and hydraulic die grinder. These burrs are essentially files which can grind in tight spaces with precision focus. Used by mechanics, machinists, tradesman, and hobbyists.

*Aluminum cut burrs are for use on non-ferrous and non-metallic materials. It is designed for rapid stock removal with minimum chip loading.

*Sharp, Durable and Well Balanced: The carbide burr set cut through extraneous material like a hot knife through butter. No wear out after a long time use. The shaft will not bend at high speed.

*Great for detail work, Not great for hogging out material. For that, we'd recommend some larger ones.

DIY Glowing LED Bottle,Engraved Porcelain Plate,Glass Plate,Granite.

Engraved Slate,Leather,Wood,Porcelain.

Max Rotation Speed: 60000 RPM, Direction of Rotation: Right Hand/Clockwise, Feed Direction: In general, burrs are used counter-rotationally or with a swinging motion. Pass the tool rapidly over the workpiece in the direction of rotation to achieve fine finishes or to achieve very smooth chamfers.

Burr Shape: End Cut Cylindrical, Ball Nosed Cylindrical, Ball, Oval, Ball Nosed Tree, Tree, Flame, Ball Nosed Cone, Cone, Inverted Cone.

Optimal Drive Tool: Straight, Angle Die Grinder, Flexible Shaft Drive, Robot. Average Drive Tool: Drill, Drill Press. Drive Type: Air or Electric

Materials Applications: Hard Wood, Balsa, Wax, Soapstone, Slate, Marble, Granite, Concrete, Steel, Hardened Steel, Weld-Seam,Stainless Steel, Brass, Copper, Bronze, Aluminum, Cast Iron, Cobalt, Nickel, Titanium, Zinc, Earthenware, Terracotta, Porcelain,Fiberglass, Plastic, Rubber, Fiber-Reinforced Plastics and so on.

Burr Applications: Carving, Engraving, Sculpturing, Polishing, Deburring, Contouring, Chamfering, Milling, Cleaning, Porting,

Cutting, Grinding, Elongating Holes etc.

Cutting, Grinding, Elongating Holes etc.

Recommendation: 1. Grinding welds, hardened steel, a tool drive output of 300-500 watts is optimal. 2. For glass hole, grinding is better than drilling, when grinding glass, please lubricate the hole with water. 3. For beginners, please choose more smaller burr head dia. than the holes’ dia. and swing-move the burr to elongate holes, otherwise the burrs will chatter in narrow holes caused by not grabbing tool firm and stably. 4. Do not press hard the tool, let speed do the work.

Why Choose Us

Chengdu Xin'chuangjie CNC Tool Co., Ltd.

is a professional enterprise specializing in the production of high-quality carbidetools, manufacturing and sales of high-quality carbide tools.The main equipment comes from Germany, the United Statesand Switzerland.Equipment industry, automobilemanufacturing industry, petroleum industry, medical machineryand other industries provide complete cutting tool solutions.The company's main business is: carbide milling cutters,carbide drills.carbide reamers,non-standard toolcustomization, taps,CNC blades,CNC tool holders. CNC toolsand machine tool accessories,etc.

In addition to a broad line of standard cutting tools, Xin'chuangjie boasts a full complement of custom tooling capabilities including an experienced team of application specialists and custom tooling designers, who provide our customers with diverse engineering capabilities. This expertise has grown organically from a combined 10-plus years of design experience. The creation of unique customer solutions can provide significant value the form of performance improvement and profitability improvement.

In addition to a broad line of standard cutting tools, Xin'chuangjie boasts a full complement of custom tooling capabilities including an experienced team of application specialists and custom tooling designers, who provide our customers with diverse engineering capabilities. This expertise has grown organically from a combined 10-plus years of design experience. The creation of unique customer solutions can provide significant value the form of performance improvement and profitability improvement.

Passivation equipment

quality inspection

Laser marking

Commonly used milling cutter warehouse

Non-standard milling cutter warehouse

CNC blade warehouse CNC cutter bar warehouse

Vietnam Exhibition

Cambodia Exhibition

Thailand Exhibition

CERTIFICATE

SALES AND SERVICE NETWORK

TRANSPORT

FAQ

Q: Are you a manufacturer? Do you have a factory?

A: We are professional manufacturers with more than 15 years of experience in the field of cutting tools.5 year of tungsten carbide export business. We have three sales stores in China, can provide you with one-stop shopping, meanwhile we have an excellent and professional sales team, we have strict desire on the quality of the carbide tools.

Q: Delivery time?

Q: Delivery time?

A: Usually the exchange time is 3-5 days after receiving the advance payment. For customized products, 15-20 days after receiving the advance payment.

Q: How long can I expect to get the sample?

Q: How long can I expect to get the sample?

A: fter you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 3-7 days. The samples will be sent to you via express and arrive in 3-5 workdays.

Q: what can you buy from us?

Q: what can you buy from us?

A: Carbide End Mills, Carbide Drills, Carbide Inserts, Carbide Thread Mills, Carbide Custom Tools, CNC Tool holders, CNC Cutter Heads, CNC Tools, etc..

Q: What's your delivery method?

A: Express, DHL, TNT, FEDEX, EMS, air and sea can be provided according to your requirements.

Q: Do you offer OEM?

Q: Do you offer OEM?

A: Yes, we do.

Q: Do you produce special carbide tools?

Q: Do you produce special carbide tools?

A: We can, we can customize it according to your drawings and samples.

Q: What are your payment terms?

Q: What are your payment terms?

A: T/T30% as a down payment and 70% delivery time. Before you pay, we will show you pictures of the product and packaging.

Похожие товары

Диаметр хвостовика 6 мм, двойная резка, форма дерева с радиусно-Концевой цилиндрической формой с радиусным концом, вращающийся карбид вольфрама

306,31 ₽ - 382,88 ₽

Циферблат внутреннего диаметра бренда Chengliang Chuan, микрометр внутреннего диаметра, высокоточный индикаторный датчик, 10-18-35-50-160 мм

12 580,25 ₽ - 13 127,21 ₽

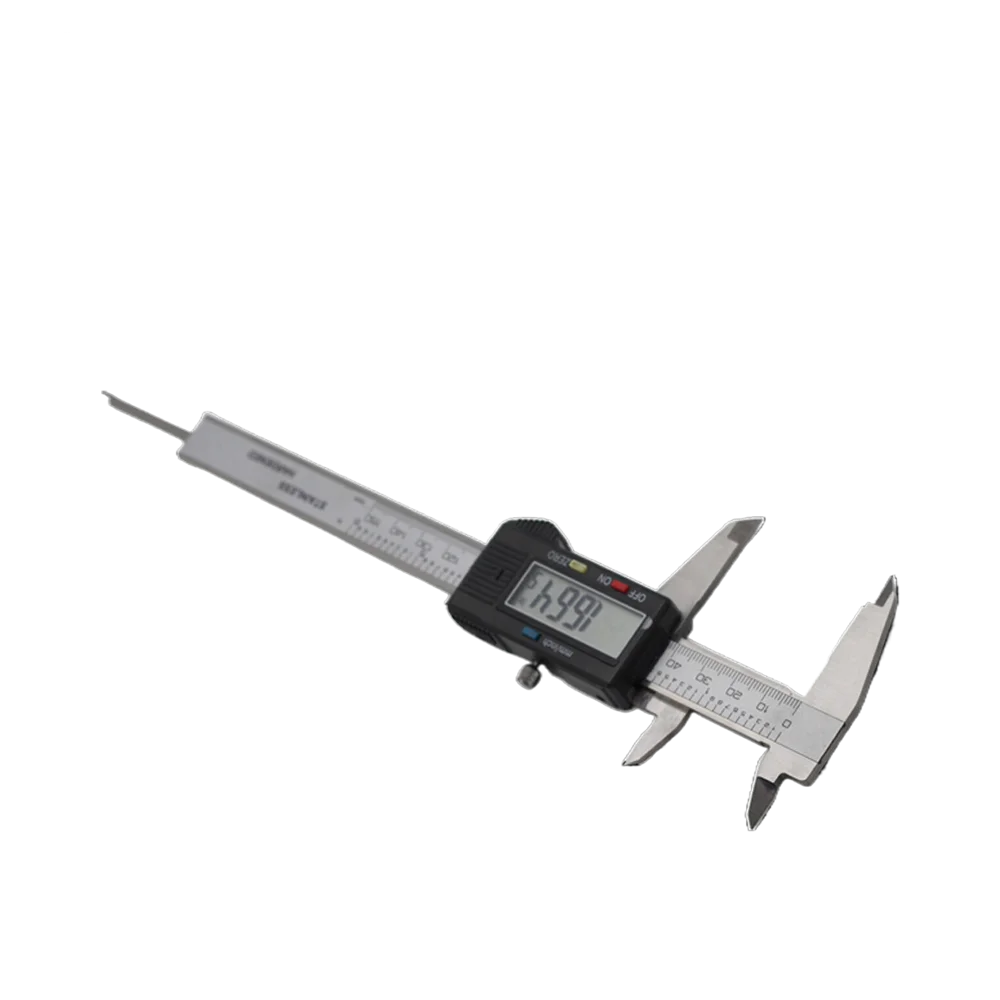

Профессиональная Оптовая Продажа 6-дюймовый цифровой штангенциркуль 0-150 мм Премиум серии цифровой штангенциркуль

1 859,69 ₽ - 1 969,09 ₽

Zund Z21 остроконечное колебательное лезвие для ЧПУ

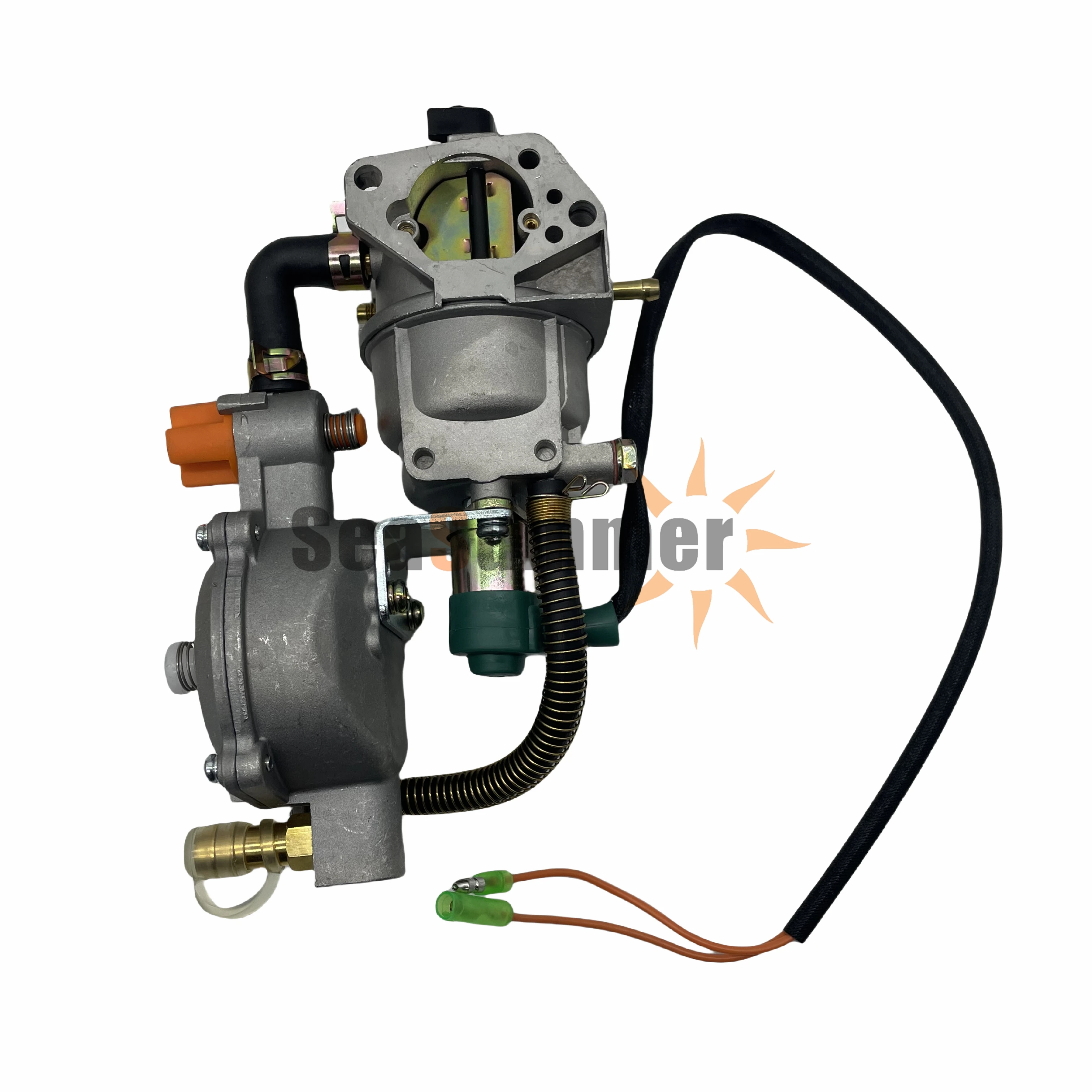

Ручной двухтопливный карбюратор для бензиновых генераторов HONDA GX390, 188F, 190F

1 476,82 ₽ - 1 586,21 ₽

Углеродистая сталь/алюминий/болт из нержавеющей стали/винт/гайки/крепежные детали для авто JX2603 специальные автомобильные детали

1,10 ₽ - 10,94 ₽

SUNSHINE DT-19N мини смарт-диапазон телефон ремонт переменного тока тестер сопротивления цифровой мультиметр для мобильных устройств

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $