Промышленная автоматическая машина для производства картофельных чипсов/продажа/полуавтоматическая линия по производству чипсов

- Категория: >>>

- Поставщик: Tianjin Hitrees Machinery Equipment Co. Ltd.Tianjin Ltd.

Сохранить в закладки 1600991291845:

Описание и отзывы

Характеристики

Product Overview

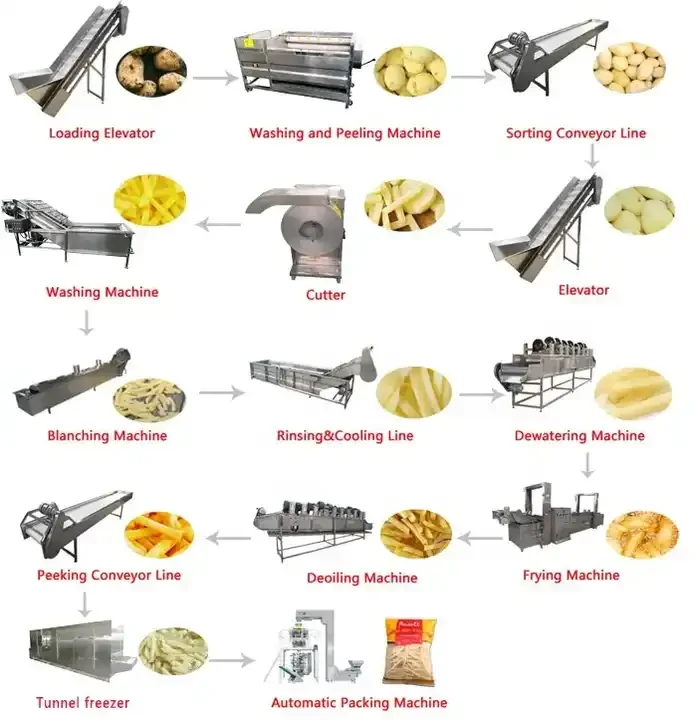

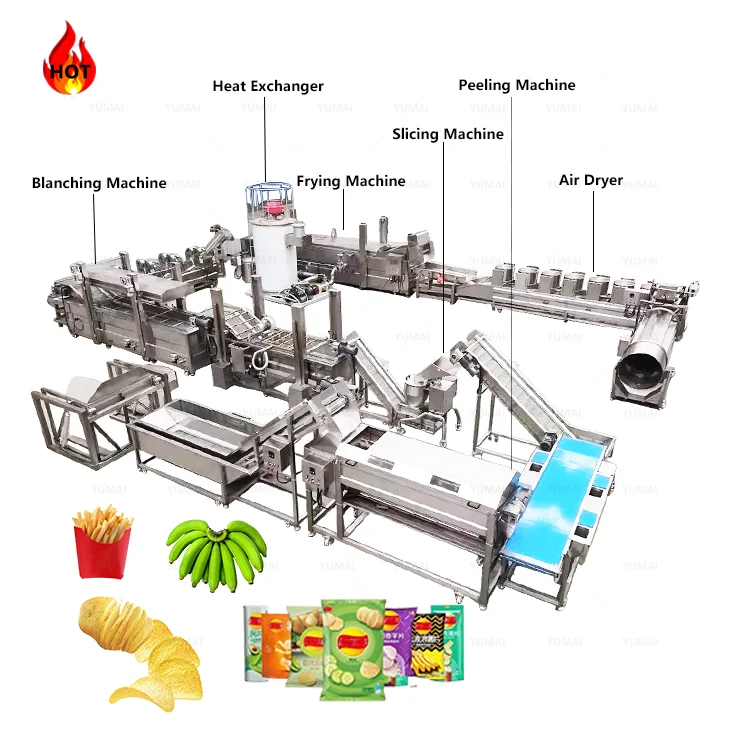

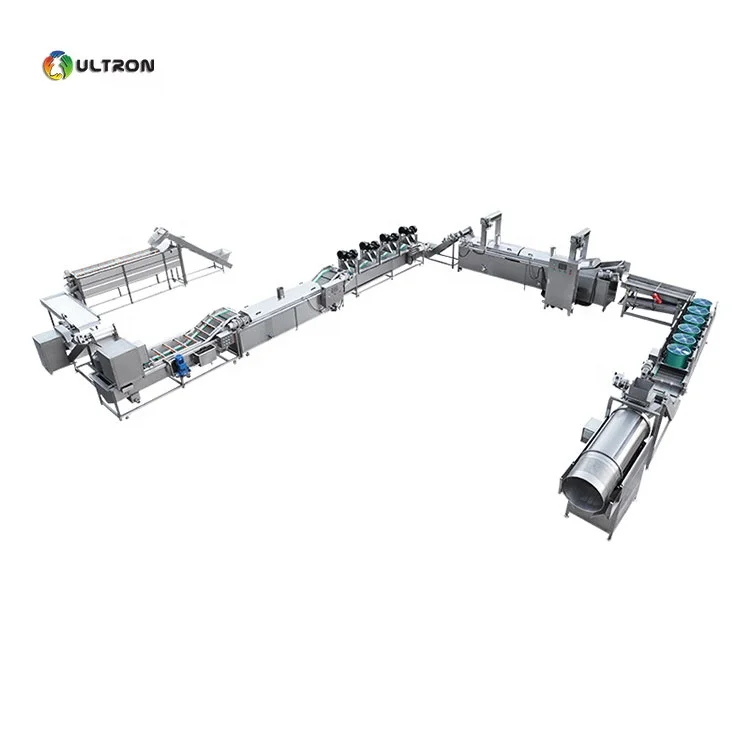

Potato chip production line

Potato chip frying production line has the characteristics of low one-time investment, low energy consumption, multiple functions, small size, high profit, easy to use and maintenance. The whole set of equipment consists of cleaning peeling, slicing (strip),

blanching, dehydration, oil and water mixed frying, deoiling, seasoning, packaging and auxiliary equipment.

Details Images

Potato Cutting Machine

1.This potato cutting machine is made of food grade stainless steel.

2.It can cut potato into stick and slice after changing different knife.

3.This machine is high efficient with good performance.The whole machine is manufactured complying with hygiene requirement.

2.It can cut potato into stick and slice after changing different knife.

3.This machine is high efficient with good performance.The whole machine is manufactured complying with hygiene requirement.

2.The water can be heated quickly.

3.It will be easy to frying the potatoes after blanching ,saving more oil and electric power.

4.Also the finished chips or french fries will be with beautiful color and best taste.

1.This machine is made of stainless steel with removable basket.

2.the machine works in high speed and finish the dewatering process within very short time.

3.Before the frying, the potato sticks or slices will be removed surface water after blanching to save the oil and avoid oil splashing

2.the machine works in high speed and finish the dewatering process within very short time.

3.Before the frying, the potato sticks or slices will be removed surface water after blanching to save the oil and avoid oil splashing

1.The machine is equipped with two individual compressor that come from France.

2.This machine can freeze fries into -18c after half cooking

3.It is also easy to operate and maintain.

2.This machine can freeze fries into -18c after half cooking

3.It is also easy to operate and maintain.

1.Chinese and English LCD touch screen

2.PLC control, easy to understand operation

3.High-precision electronic scale weighing, high precision

4.All stainless steel structure, easy to clean and corrosion resistant

5.Artificial bagging, photoelectric induction cutting

6.Vibrator feeding, high speed and high precision

2.PLC control, easy to understand operation

3.High-precision electronic scale weighing, high precision

4.All stainless steel structure, easy to clean and corrosion resistant

5.Artificial bagging, photoelectric induction cutting

6.Vibrator feeding, high speed and high precision

PRODUCT SPECIFICATIONS

Slicer | 1.Size: 600*500*900 2.Section size: 2-9mm 3.Power: 1.5kw 4.Material: 304 |

Blanching machine (frequency control) | 1.Size: 2500*950*1250 2.Net belt width: 600mm 3.Power: 50kw 4.Electric heating power: 48kw |

Fryer (frequency control) | 1.Size: 2500*1200*1550 2.Net belt width: 600 3.Power: 50kw 4.Electric heating power: 48kw |

Seasoning machine (frequency control) | 1.Size: 1400*800*1550mm 2.Drum diameter: 700mm 3.Drum length :1200mm 4.Power: 0.75kw |

Advantage

Adopt double net belt to transport potato chips, up and down the net belt can be converted. Users can adjust the transmission speed of the net belt according to the different fried food, equipped with burners, fast temperature, high production efficiency. Electric lifting system is set up to facilitate workers to clean and maintain the body. In addition, there are automatic smoke exhaust system and constant temperature continuous production system to ensure that workers have a good working environment to avoid smoke and fire at the same time to ensure that the food frying temperature is consistent, so that the fried food taste more crispy.

Packing&Shipping

Company Introduction

Tianjin Hitrees Machinery Equipment Co.,Ltd specialized to produce and sale food industry equipment, including cooling & freezing equipment,bakery equipment,kitchen equipment,ice cream machines,processing lines. Meanwhile, we can also provide site installation and commissioning services, and craft consultation services.

We have rich experience of providing food machines for all over the world, North America, South America, Europe, Australia, Africa, Southeast Asia and the Middle East areas included.

Many experienced engineers can design machines exactly according to your specific requirement. And after-sale service team is ready for offering help at any time when you have any problems.

We have rich experience of providing food machines for all over the world, North America, South America, Europe, Australia, Africa, Southeast Asia and the Middle East areas included.

Many experienced engineers can design machines exactly according to your specific requirement. And after-sale service team is ready for offering help at any time when you have any problems.

FAQ

Q1:Do you accept customised orders?

A1:Yes, ODM and OEM are welcome.

Q2: What is the lead time?

A2: It usually takes about 45 days.

Q3: What is your payment terms?

A3: We accept L/C D/A D/P T/T Western Union MoneyGram.

Q4: Do you offer after-sale technical support?

A4: Yes, with many years of experience, the Hitrees After Sales department is your partner in keeping your processing equipment up and running. We offer knowledge, expertise, and state-of-art equipment. We provide on-line technical service and support throughout the machine’s entire lifetime, enabling you to focus on your core business.

Q2: What is the lead time?

A2: It usually takes about 45 days.

Q3: What is your payment terms?

A3: We accept L/C D/A D/P T/T Western Union MoneyGram.

Q4: Do you offer after-sale technical support?

A4: Yes, with many years of experience, the Hitrees After Sales department is your partner in keeping your processing equipment up and running. We offer knowledge, expertise, and state-of-art equipment. We provide on-line technical service and support throughout the machine’s entire lifetime, enabling you to focus on your core business.

Похожие товары

2018 индивидуальная полуавтоматическая мелкомасштабная машина для производства картофельных чипсов заводская цена продажи

6 300,00-6 700,00 $

100-500 кг/ч машина для производства картофеля замороженного фри

Производственная линия замороженного картофеля фри/Оборудование для фри

Китайский производитель машина для обработки свежего картофеля маниока приготовления замороженного фри

7 000,00-10 000,00 $

Машина для переработки картофеля фри электрическая полуавтоматическая Картофельная стружка Fry Production Line

Машина для резки банановых чипсов и фруктов оборудование обработки ломтиков корня лотоса сладкого картофеля

1 100,00-1 300,00 $

Машина для нарезки картофеля лотоса машина сладкого банановых чипсов емкость 600 кг/ч коммерческое оборудование корнеплодов

1 100,00-1 300,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $