Оптовая продажа под высоким давлением заказ литье из алюминиевого сплава

- Категория: >>>

- Поставщик: Tiger Tech Precision Parts (huizhou) Co. Ltd.Tiger Ltd.

Сохранить в закладки 1600996689515:

Описание и отзывы

Характеристики

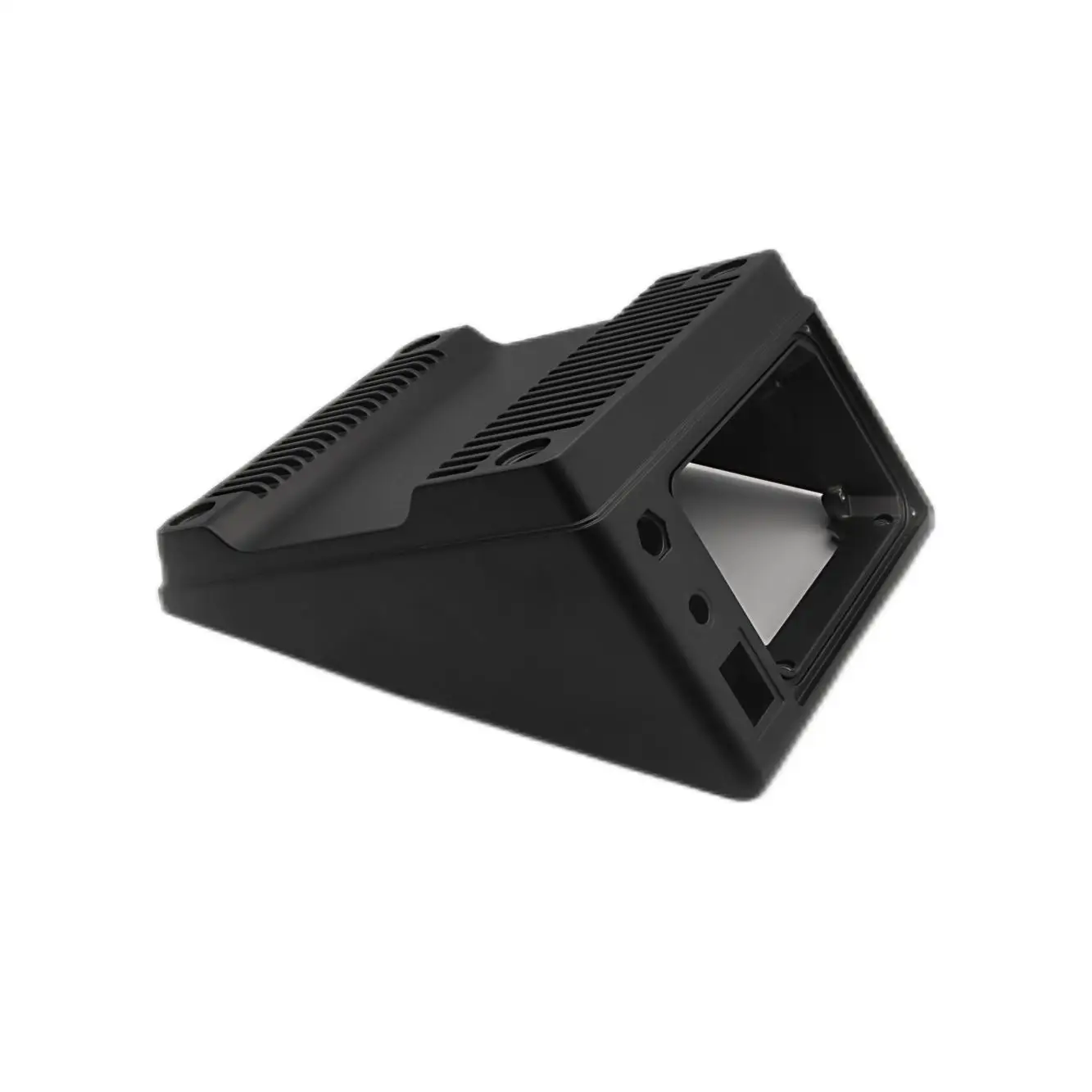

Wholesale High Pressure Customized Moulding Shell Aluminum Alloy Die Casting

Place of Origin | Guangdong, China |

Brand Name | OEM |

Model Number | OEM |

Material | Aluminum |

Machining Process | CNC Precision Machining |

Type | Aluninum Die Casting |

Standard | ISO 9001 |

Application | Shell |

Tiger Tech Precision Parts (Huizhou) Co,ltd.

was established in 2007, which is a professional production of aluminum and zintalloy precision die-casting of high-tech enterprise. Aluminum alloy products include new energy BMS shell and battery pack components (end plate, bracket, explosion-proofvalve, arplug hardware,etc), walkie-takie shell, LED lamp holder, routershell, etc Zinc alloy products include auto parts (shift handball, automatic tailgate controller accessories and rain bracket accesories) , video distributor, connector housing, torsion, communication cabinet pats, fishing gear drive gear plate, cell phoneantenna holder, high-end handbag hardware, etc. The main clients are Japanese, French, American, Chinese taiwanese and Chinese mainland. Tiger Tech not only make precision parts, but also appearance pieces, the combination of these two is the differentiation of our pursuit of development.

The company has advanced Japanese Takazuka die-casting machine, U 2 machine, full-automatic die-casting machine as well as a variety of supporting perfect peripheral processing equipment. And has a group of professional design, manufacturing technical team, the backbone of technical personnel engaged in die-casting industry nearly 20years of technical and manufacturing experience. In addition, the company has passed IS0 9001 : 2015 and IATF 16949:2016 certification, advanced quality management system for the protection of product quality.

The company has advanced Japanese Takazuka die-casting machine, U 2 machine, full-automatic die-casting machine as well as a variety of supporting perfect peripheral processing equipment. And has a group of professional design, manufacturing technical team, the backbone of technical personnel engaged in die-casting industry nearly 20years of technical and manufacturing experience. In addition, the company has passed IS0 9001 : 2015 and IATF 16949:2016 certification, advanced quality management system for the protection of product quality.

Professional:

16 years of deep-rooted die-casting industry, with rich experience inproduct manufacturing

16 years of deep-rooted die-casting industry, with rich experience inproduct manufacturing

Convenient:

Provide one-stop service from mold design to finished product packaging and transportation.

Confidentiality:

According to customer requirements, we can sign NDA, from design to finished product process all information strictly confidential.

Timeliness:

Years of foreign trade experience, and cooperate with the major logistics companies to ensure the timely delivery of products to customers.

High quality:

Our company has passed ISO9001:2015 and IATF 16949:2016 certification, adopting the world's advanced quality management system. With video detection andother advanced testing equipment, to ensure that each product before leaving the factory after strict quality testing.

Reasonable price:

We have our own factory, no agent can offer more competitive price.

FAQ

1. Who are we?

We are based in Guangdong, China, start from 2022, sell to Domestic Market(50.00%), Eastern Asia(30.00%), North America(8.00%), Western Europe(5.00%), Southern Europe(3.00%), South America(2.00%), Northern Europe(2.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Zinc Casting Parts, Aluminum Casting Parts, Magnesium Casting Parts, Iron Casting Parts, Copper Casting Parts

4. Why should you buy from us not from other suppliers?

1. 16 years of experience in aluminum alloy and zinc alloy casting.

2. The national high-tech enterprise certification.

3. Quality management system through the SGS certification.

4. One-stop service from mold customization to finished product delivery.

5. Payment terms?

Mold cost: 50% prepay upon order confirm, balance after sample approved; Mass production: 50% prepay, balance after B/L available.

We are based in Guangdong, China, start from 2022, sell to Domestic Market(50.00%), Eastern Asia(30.00%), North America(8.00%), Western Europe(5.00%), Southern Europe(3.00%), South America(2.00%), Northern Europe(2.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Zinc Casting Parts, Aluminum Casting Parts, Magnesium Casting Parts, Iron Casting Parts, Copper Casting Parts

4. Why should you buy from us not from other suppliers?

1. 16 years of experience in aluminum alloy and zinc alloy casting.

2. The national high-tech enterprise certification.

3. Quality management system through the SGS certification.

4. One-stop service from mold customization to finished product delivery.

5. Payment terms?

Mold cost: 50% prepay upon order confirm, balance after sample approved; Mass production: 50% prepay, balance after B/L available.

6. Delivery time?

Normally 25~40 days

7. Transaction process?

Consultation → Send the drawing (2D / 3D) → Confirm requirements → Quoted price → 50% mold fee → Sample making → Sample confirmation → 50% mold fee → Confirm mass production order → 50% prepay → Mass production → Balance payment → Shipping

8. How to connect us?

Consultation email: project02@tigertech-hz.cn Miss Jenny

Похожие товары

Изготовленные На Заказ алюминиевые литейные формы изготовленные на заказ детали

EB природный газ промышленный кобальтовый сплав точное литье для центробежного

Прецизионные пользовательские обратные R & D Кобальт хромированный сплав Inconel литые электронные лучевые сварочные услуги для оборонной камеры сгорания

6 313,98-7 921,18 ₽

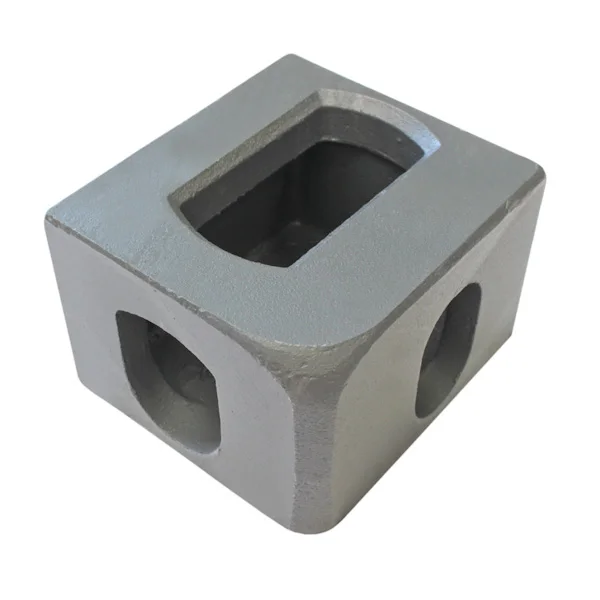

Стальной грузовой контейнер угловой отливной пост iso фитинг

1 722,00-2 066,40 ₽

Воспроизводимый угловой алюминиевый контейнер

261 061,18 ₽

Заводская распродажа стальные контейнерные Угловые блоки угловые фитинги

1 722,00-2 066,40 ₽

Контейнерные детали для транспортировки контейнерные угловые фитинги стальные Угловые литейные блоки

1 722,00-2 066,40 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $